Siemens Industry, Inc. 5300 Triangle Parkway, Norcross, GA 30092

A5E31166447A-002

Auxiliary Contact

A maximum of two auxiliary units can be installed in the re

-

cesses of each contactor (see Fig. 5 for location and bottom of

Table 4 for the auxiliary units catalog numbers and their contact

configuration). Auxiliary units mount by means of spring clip

and retainer screw. To remove the unit rotate the retainer screw

several times (counter-clockwise) and then slide the auxiliary

contact unit out of the recess.

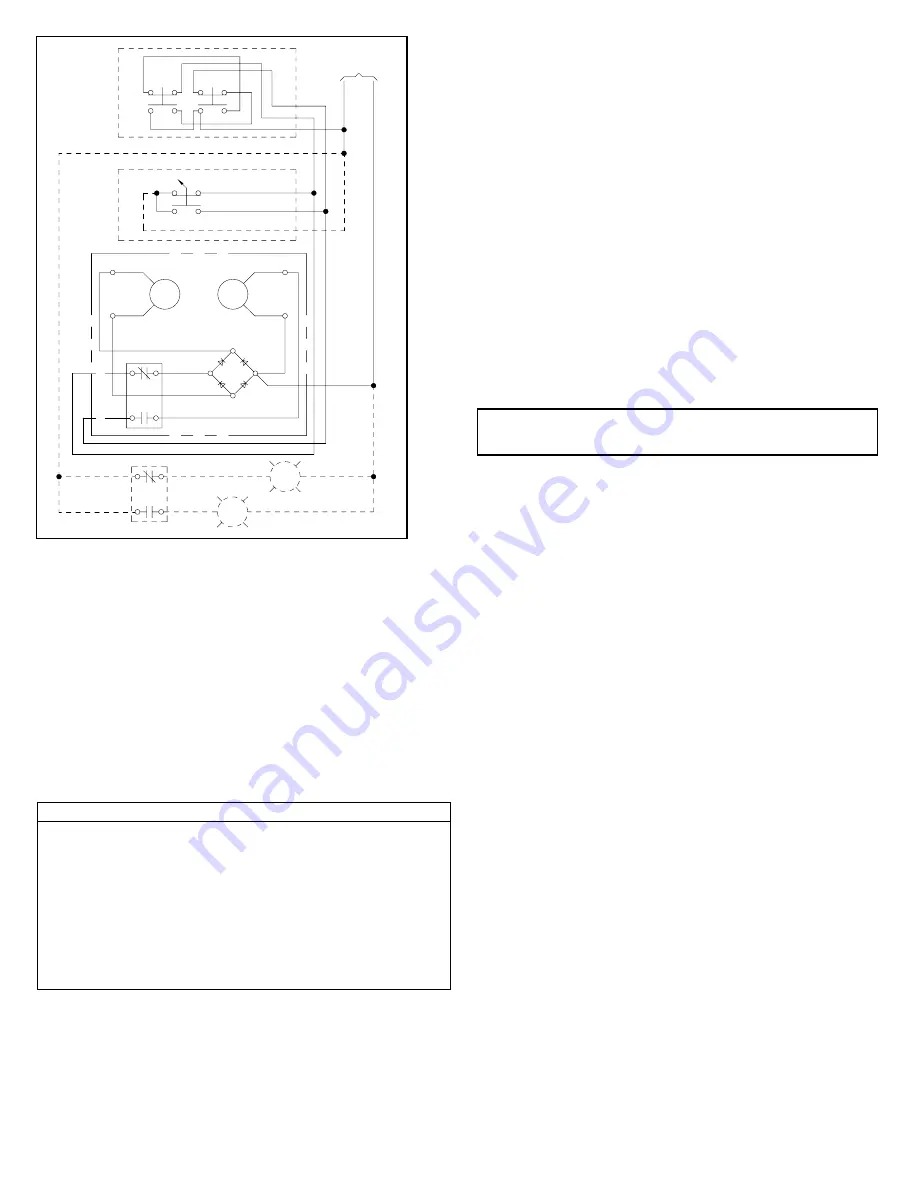

Fig. 2 Connection Diagram for Common/Separate Control

with Momentary Pushbutton or ON-OFF Selector

Switch

Table 3 - Coil

Voltage

VAC

Freq.

Hz

Part Number

2-4 Pole 5 Pole

24

60 Hz

CLMC4C024

CLMC5C024

110/120

50/60 Hz

CLMC4C120

CLMC5C120

208

60 Hz

CLMC4C208

CLMC5C208

220/240

50/60 Hz

CLMC4C240

CLMC5C240

277

60 Hz

CLMC4C277

CLMC5C277

440/480

50/60 Hz

CLMC4C480

CLMC5C480

550/600

50/60 Hz

CLMC4C600

CLMC5C600

CAUTION -

All control wiring for contactor operation must only be made to

the coil isolation contact terminals #2, #3 and L2 terminal con-

nection points. Wiring made to any other terminal points will

burn out the coil and diode. If a coil burnout occurs, both the

coil and the diode must be replaced.

Coil Replacement

–

refer to Figure 1, Table 3.

Loosen the two screws at each side of the upper base and re

-

move the wire connections. Loosen the assembly screws (1).

Pull the loosened upper base structure (2) forward. Unplug

the coil (3) from the upper base, plug in a new coil and re

-

place the upper base structure while depressing the kick-out

springs (4) to ensure they set in the molded seats in the cross-

bar (5). Reconnect the four coil leads. Tighten the assembly

screws referring to Table 2. Mechanically operate the unit to

ensure there is no binding of the crossbar.

Contact Inspection

–

refer to Figure 1

Loosen the two arc chute screws (6) located immediately

above and below the nameplate and remove the arc chute

(7). The contacts (8) are visible. Re-tighten the screws per

Table 2.

Contact Wear and Replacement –

refer to Figure 1,

Table 4.

CAUTION: Install arcbox prior to energization

Contacts are designed for a long service life based on a spe

-

cific electrical load under normal service and environmental

conditions. If any one of these factors is altered, a shorter ser

-

vice life or a breakdown will result. Contactors are subject to

both mechanical and electrical wear during their operation. In

most cases mechanical wear is insignificant. The erosion of

the contacts is due to electrical wear. During arcing, material

from each contact is vaporized and blown away from the useful

contacting surface.

Note:

When contact replacement is required, it is necessary

to replace both stationary and moving contacts plus moving

contact overtravel springs. After replacement, manually oper-

ate switch to be sure binding does not occur.

After removing the arc chute (7) and with replacement contacts

in hand, compress the overtravel spring (9) and remove the

moving contact (8) from the crossbar (5). Remove any power

connections. Remove screws (10) and lift out the stationary

contact carriers (11). The new contacts are then installed by

reversing the above procedure and referencing Table 2 for

torque specifications. Moving contacts should be free to move,

overtravel spring seated, and the crossbar free to move when

the arc chute is in position. Silver cadmium oxide contact but-

tons require NO dressing or lubrication during their life.

Magnet - Armature Assembly

Self alignment and permanent air gap features of the magnet

armature make replacement unnecessary. Mating pole face

surfaces should be kept clean.

OFF

ON

OFF

ON

VOLTAGE

CONTROL

(L1)

1

(L2)

X2

ON

OFF

( + )

( - )

BLACK

( + )

( - )

AC

AC

L2

RED

WHITE

CLMFCCK11

3

2

RE

D

CLMFCAK11

OFF

ON

RE

D

CLM CONTACTOR

All manuals and user guides at all-guides.com