27

5996

8

2020

-

SAC 240 & SAC 320

MG_0010

P.O. Box 519

N-1612 Fredrikstad Tel: +47 69 30 00 60

Sleipner Motor

AS

Copyright all RIGHTS reserved Sleipner Motor

AS

P/N:

DWG No:

All Dimensions in mm

Drawn

Approved

Revised

Date

Name

Sheet

Sh.

Rev:

E

D

C

B

F

A

E

D

C

B

F

A

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

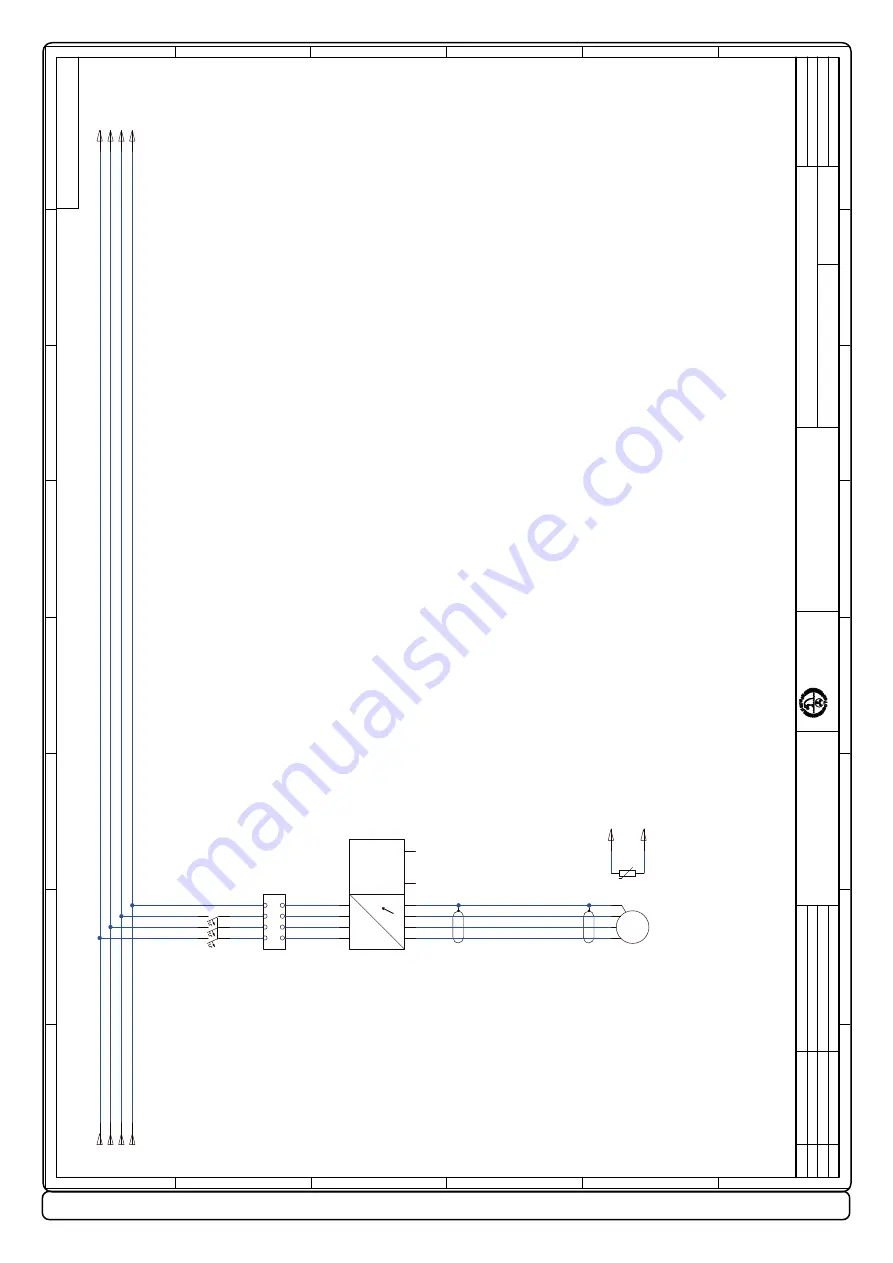

AC

3

SAC PDC 301 -

ACS580/ACH580

VFD Power

BS-013-EL-161

E

18.04.18

BS

07.01.20

SV

M

3

~

~

~~

~

T1

T2

-U2

L1

L2

L3

PE

1

2

3

4

5

6

Module Circuit Breaker 3P

-F1

L3

PE

L1

L2

L1

L2

L3

PE

U1

V1

W1

UDC+

UDC-

PE

U2

V2

W2

PE

ACS580/ACH580

-U1

AC Motor 3

-M1

1

2

U

V

W

PE

AC Motor 3

-M1

Temperature Sensor

Use shielded cable designed for use with variable frequency drives.

High voltage DC bus. Do not connect.

MG_0009

P.O. Box 519

N-1612 Fredrikstad Tel: +47 69 30 00 60

Sleipner Motor

AS

Copyright all RIGHTS reserved Sleipner Motor

AS

P/N:

DWG No:

All Dimensions in mm

Drawn

Approved

Revised

Date

Name

Sheet

Sh.

Rev:

E

D

C

B

F

A

E

D

C

B

F

A

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

PDC-301

3

SAC PDC 301 -

ACS580/ACH580

Control

BS-013-EL-161

E

18.04.18

BS

07.01.20

SV

Power Management System

Thruster

Enable

Power

Limit

Thruster

Request

Aux. voltage output and programmable digital inputs

Serial data link switches

Relay output RO2 [Running]

250V

AC /30V DC, 2A

Relay output RO1 [Ready run]

250V

AC /30V DC, 2A

EFB (EIA-485) / Embedded fieldbus

Safe torque o

ff

Reference voltage and analog inputs and outputs

RO2A

RO2C

DGND

+24V

AO1

AO2

AGND

RO3B

RO3A

RO3C

IN2

Panel Port

Relay output RO3 [Fault (-1)]

250V

AC /30V DC, 2A

BIAS

S5 (BIAS)

ON

S4 (TERM)

ON

TERM

X14

Option slot 2

X13

Option slot 1

Voltage/Current selection switches

U

S1

AI1 (U/I)

U

S2

AI2 (U/I)

I

S3

AO1 (U/I)

U

I

I

All control boards do not have switches S1, S2 and S3. In that case, select voltage or current for inputs AI1 and

AI2 and output

AO1 with parameters.

DI6

DI5

DI4

DI3

DI2

DI1

AGND

+10V

AI2

AGND

IN1

SGND

OUT2

OUT1

B+

RO2B

DCOM

SCR

AI1

A-

DGND

RO1B

RO1A

RO1C

SIDE-POWER

S-link

VFD

(RS-485)

-W2.X1

*5

T2

T1

6 1321

*5

*5

PMS

ACS580/ACH580

ACS580/ACH580

-U1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

RJ45

34

35

36

37

38

29

30

31

19

20

21

22

23

24

25

26

27

X1

X2 & X3

X4

X5

X6

X7

X8

6 1326

-X1

PDC-301

-U4

Optional

Red Wire: Cut and Insulate

Ground the outer shield of the cable 360 degrees under the grounding clamp on the grounding shelf for the control cables inside VFD.

S-Link

WH

BU

BK