We reserve the right to make changes without prior notification

UM 18-5111_

8 010 758.0704 GO KE

ENGLISH

Ultrasonic sensor

with one or two switching outputs

Operating Instructions

Safety Specifications

‡ No safety component in accordance with EU machine

guidelines.

‡ Read the operating instructions before star ting operation.

‡ Connection, assembly, and settings only by competent

technicians.

‡ Protect the device against moisture and soiling when

operating.

Proper Use

The UM 18-5111_ is an ultrasonic sensor and is used for

non-contact detection of objects, animals, and people.

Starting Operation

A

Only UM 18-51111 and UM 18-51115

T

T

T

T

Teach-in switching output:

each-in switching output:

each-in switching output:

each-in switching output:

each-in switching output:

– Place the object at the desired switching distance from

the sensor.

– Connect L+ for approx. 3 s to the control input (MF).

B

Only UM 18-51112 and UM 18-51114

The operating modes are set via the control input (MF).

The switching output 1 (Q

1

/Q

–

1

) can be set by connecting

L+ to the control input (MF). Analog to this, the switching

output 2 (Q

2

/Q

–

2

) can be set by connecting M to the

control input (MF).

The Teach-in concept is explained using the example of

switching output 1 (Q

1

/Q

–

1

). The response of LED1 and

LED2 must be swapped in points

B1

to

B5

for the

switching output 2 (Q

2

/Q

–

2

).

B1

Switching function

T

T

T

T

Teach-in switching point

each-in switching point

each-in switching point

each-in switching point

each-in switching point

– Place the object at the desired switching distance in

front of the sensor ; both LEDs display the state of the

switching outputs

– connect L+ to the control input (MF), LED1 blinks, LED2

maintains its state

– until both LEDs blink simultaneously (after approx. 3 s)

– remove L+ from the control input (MF); both LEDs blink

alternately

– connect L+ to the control input (MF) again; LED1 blinks,

LED2 is off

– remove L+ from the control input (MF) after approx.

1 s; both LEDs display the state of the switching outputs.

The switching point is stored permanently, and the sensor

is ready to operate.

B2

Additional functions

T

T

T

T

Teach-in max.

each-in max.

each-in max.

each-in max.

each-in max. switching point (limiting scan r

switching point (limiting scan r

switching point (limiting scan r

switching point (limiting scan r

switching point (limiting scan range)

ange)

ange)

ange)

ange)

– Do not place any object in front of the sensor ; both

LEDs display the state of the switching outputs

– continue as under point

B1

.

B3

T

T

T

T

Teach-in in windo

each-in in windo

each-in in windo

each-in in windo

each-in in window oper

w oper

w oper

w oper

w operation

ation

ation

ation

ation

– Place the object at a switching distance near the sensor ;

both LEDs display the state of the switching outputs

– connect L+ to the control input (MF), LED1 blinks, LED2

maintains its state

– until both LEDs blink simultaneously (after approx. 3 s)

– remove L+ from the control input (MF); both LEDs blink

alternately

– place the object at switching distance near the sensor

– connect L+ to the control input (MF) again; LED1 blinks,

LED2 is off

– remove L+ from the control input (MF) after approx.

1 s; both LEDs display the state of the switching outputs.

The window with the switching point near the sensor and

far from it is stored permanently, and the sensor is ready to

operate. If the user tries to set the window width < 5 mm,

B1

(switching point with an object) is set. If a distance is

taught in the detection range of the sensor and a second

one is outside of the detection range, both LEDs blink for

3 seconds simultaneously fast (error display). The old

switching points are maintained.

B4

T

T

T

T

Teach-in in object betw

each-in in object betw

each-in in object betw

each-in in object betw

each-in in object between sensor and background:

een sensor and background:

een sensor and background:

een sensor and background:

een sensor and background:

– Reflector : Pay attention to alignment: 90° sensor to

reflector, smooth surfaces.

– Place the reflector in front of the sensor ; both LEDs

display the state of the switching outputs

– connect L+ to the control input (MF), LED1 blinks, LED2

maintains its state

– until both LEDs blink simultaneously (after approx. 3 s)

– remove L+ from the control input (MF); both LEDs blink

alternately

– connect L+ to the control input (MF) again; LED1 blinks,

LED2 is off

– until LED1 lights (approx. 10 s)

– remove L+ from the control input (MF); both LEDs

display the state of the switching outputs.

The window is set symmetrically around the fixed reflector

with ± 8 % of the switching distance. If a distance is taught

in the detection range of the sensor and a second one is

outside of the detection range, both LEDs blink for 3

seconds simultaneously fast (error display). The old

switching points are maintained.

B5

T

T

T

T

Teach-in output function (Q/

each-in output function (Q/

each-in output function (Q/

each-in output function (Q/

each-in output function (Q/Q

Q

Q

Q

Q

–

–

–

–

–

)))))

– Connect L+ to the control input (MF), LED1 blinks,

LED2 maintains its state; both LEDs blink simultaneously

after 3 s

– until both LEDs blink alternately fast (approx. 13 s)

– remove L+ from the control input (MF); LED2 blinks

fast; LED1 displays the output function;

LED1 on = Q, LED1 off = Q

–

– while the LED2 blinks fast, the output function is

inver ted each time L+ is connected. LED1 on = Q,

LED1 off = Q

–

.

If L+ is not connected for 10 s, the set output function

remains active; the sensor is ready to operate.

B6

Switch betw

Switch betw

Switch betw

Switch betw

Switch between

een

een

een

een T

T

T

T

Teach-in and synchronization

each-in and synchronization

each-in and synchronization

each-in and synchronization

each-in and synchronization

Self-synchronization: Connect sensors via PIN 5 (max. 10

can be switched parallel). As a result, the “detection range”

is increased. When there is parallel operation of the

sensors, the installation distance sideways must be smaller

than 10 cm. A type of “grid operation” is achieved via the

synchronization.

– Switch of the power to the sensor (switch off the

operating voltage)

– connect M to the control input (MF), switch on the

operating voltage, keep M connected to the control

input (MF); LED2 blinks fast, and LED1 displays the state

of the switching output

UM 18-51111

UM 18-51112

UM 18-51114

UM 18-51115

2

UM 18-5111_

– until both LEDs blink simultaneously (after approx. 3 s),

– remove M from the control input (MF); LED1 blinks fast,

and LED2 displays the operating mode; LED2 on =

Teach-in mode, LED2 off = synchronization mode

– while the LED1 blinks fast, there is a switch between

Teach-in and synchronization each time M is connected.

LED2 on = Teach-in mode; LED2 off = synchronization

mode.

If M is not connected for 10 s, the set output function is

adopted; the sensor is ready to operate. Do not connect

PIN 5 in RUN mode.

B7

Factor

Factor

Factor

Factor

Factor y setting

y setting

y setting

y setting

y setting

– Switch off the operating voltage

– connect M to the control input (MF), switch on the

operating voltage, keep M connected to the control

input (MF); LED2 blinks fast, and LED1 displays the state

of the switching output.

Both LEDs blink simultaneously after 3 s.

– until both LEDs display the switching state

(after approx. 13 s)

– remove M from the control input (MF).

The sensor has its factory setting.

Maintenance

SICK sensors do not require any maintenance. We recommend

that you clean the external lens surfaces and check the screw

connections and plug-in connections at regular inter vals.

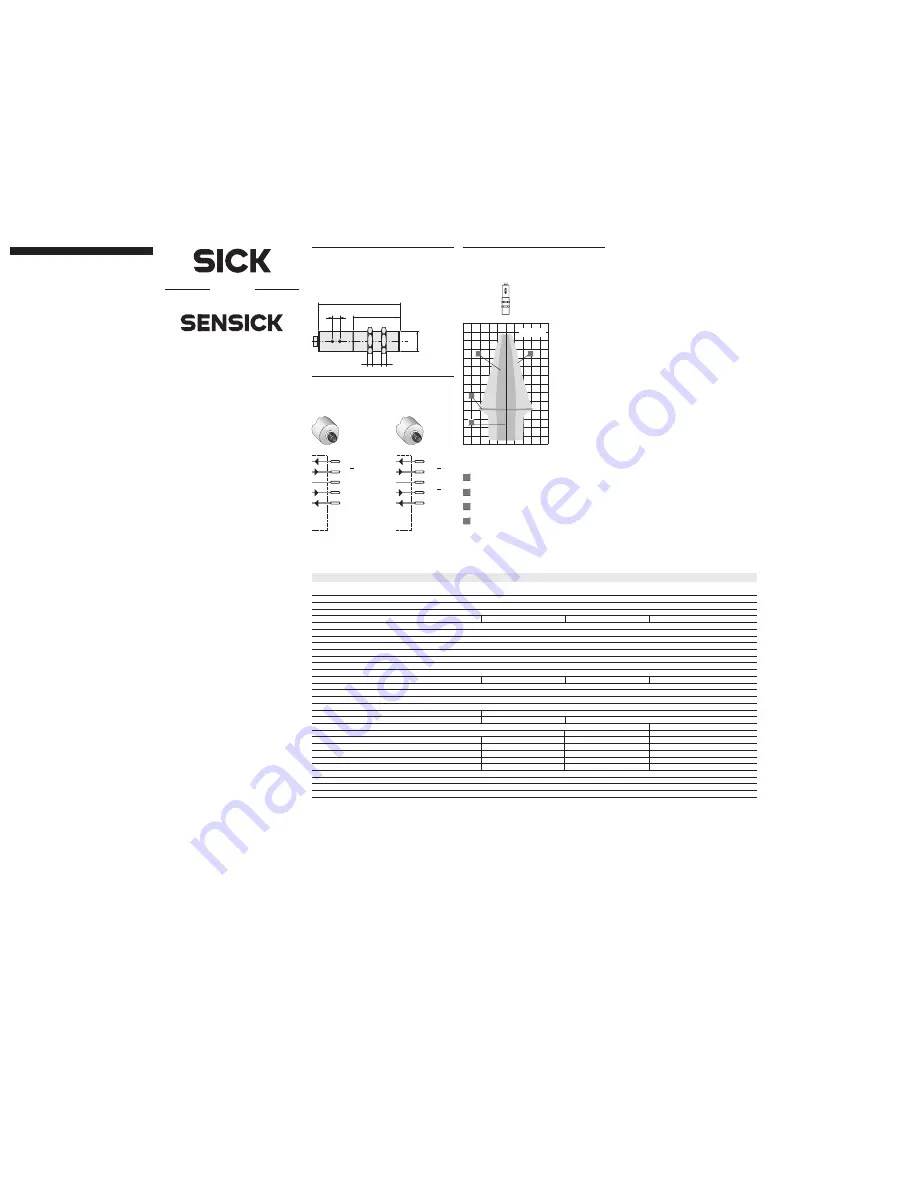

1

M18x1

5

5

73.3

47

5

UM 18-51111

UM 18-51115

UM 18-51112

UM 18-51114

1

L+

Q, Q

NC

4

3

2

M

brn

blk

blu

5

MF

gra

wht

1

L+

Q , Q

Q

, Q

4

3

2

M

brn

blk

blu

5

MF

gra

wht

2

2

1

1

–80

–40

0

40

80

[mm]

50

100

150

200

250

300

350

UM 18-5111_

250 mm

1

2

3

4

2

Operating distance

Maximum scanning

distance

3

1

4

Aligned plate

500 x 500 mm

2

Tube diameter 10 mm

UM 18-

51111

51112

51114

51115

Oper

Oper

Oper

Oper

Operating distance

ating distance

ating distance

ating distance

ating distance

30 mm ... 250 mm (< 350 mm)

(maxim

(maxim

(maxim

(maxim

(maximum scanning distance)

um scanning distance)

um scanning distance)

um scanning distance)

um scanning distance)

Ultrasonic frequency

320 kHz

Resolution

0.36 mm

Reproducibility

typ. ±0,15 % of final value

Accuracy

≤

2 % of final value

≤

2 % of final value

Oper

Oper

Oper

Oper

Operating v

ating v

ating v

ating v

ating voltage

oltage

oltage

oltage

oltage

U

B

= 10 ... 30 V DC

Residual ripple

10 %

Idle current consumption

≤

40 mA

Housing material

Brass tube, nickel plated

Plastic parts: PBT

Ultrasonic converter : polyurethane foam, epoxy resin with glass content

Enclosure rating to EN 60 529

IP 67

Connection type

Plug M12, 5-pin

Display elements

2 LEDs

2 LEDs

Ambient temperature

Operating: –20 °C ... +70 °C

Storage:

–40 °C ... +85 °C

Weight

65 g approx. (with 2 nuts)

Control input MF

Teach-in

Switching outputs PNP, inver table

1 x PNP

1)

2 x PNP

2)

Switching outputs NPN, inver table

1 x NPN

3)

2 x NPN

4)

Temperature compensation

No

yes

yes

no

Synchronisation option

No

yes

yes

no

Functional display

No

yes

yes

no

Scanning mode

Yes

yes

yes

yes

Deflector mode

No

yes

yes

no

Switching hysteresis

2.0 mm ±10 %

Switching frequency

15 Hz

Response time

32 ms

Standby delay

< 300 ms

3

1)

(L+) – 2 V, l

max

= 500 mA, shor t-circuit proof

3)

M + 2 V, l

max

= 500 mA, shor t-circuit proof

2)

(L+) – 2 V, l

max

= 2 x 500 mA, short-circuit proof

4)

M + 2 V, l

max

= 2 x 500 mA, shor t-circuit proof