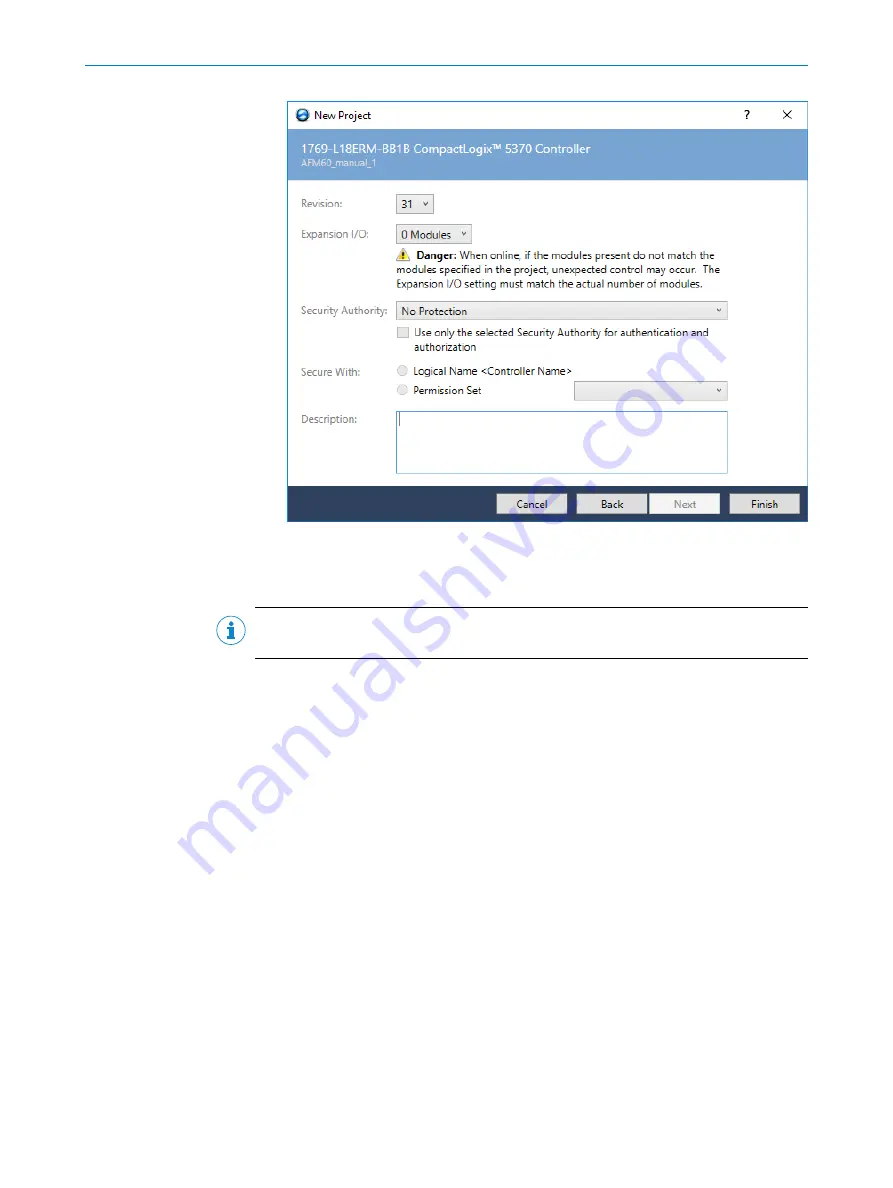

Figure 30: Projecting the hardware

4.

Click

OK

.

✓

The

RSLogix 5000 [Name]

window opens.

NOTE

Type and Chassis Type must match your controller.

You can then integrate and configure the encoder in the project in three ways:

•

Using an EDS file (

see "Integration and configuration using an EDS file", page 52

•

Using the function block (

)

•

As generic module (

see "Integration of the encoder as generic module", page 67

)

Due to the fast and easy integration, we recommend integrating the encoder using an

EDS file.

Please note that with older encoders before DateCode (YYWW) 1535 (firmware version

before 2.1.8), only integration as generic module is possible.

5.4

Integration and configuration using an EDS file

The EDS file (electronic data sheet) contains all information about the parameters and

the operating modes of the absolute encoder. The absolute encoder can be configured

and put into operation using the EDS file.

5.4.1

Requirements

•

An Allen-Bradley control system with

RSLogix 5000

control software V22 or later is

used (or another controller that allows integration using an EDS file).

•

The encoder is integrated into the EtherNet/IP network (

•

The EDS file has been integrated into the control software using the Rockwell

Hardware Installation Tool.

5

CONFIGURATION USING A PLC

52

O P E R A T I N G I N S T R U C T I O N S | AFS/AFM60 EtherNet/IP

8014213/1EF3/2021-12-08 | SICK

Subject to change without notice