-17-

Model W1768/W1769 (For Machines Mfg. Since 5/07)

O

PE

R

ATIO

NS

OPERATIONS

General

This machine will perform many types of operations

that are beyond the scope of this manual. Many of these

operations can be dangerous or deadly if performed

incorrectly.

The instructions in this section are written with the

understanding that the operator has the necessary

knowledge and skills to operate this machine.

If.at.

any.time.you.experience.difficulties.performing.any.

operation,.stop.using.the.machine!

If you are an inexperienced operator, we strongly

recommend that you read books, trade articles, or seek

training from an experienced power feeder operator

before performing any unfamiliar operations.

Above.all,.

your.safety.should.come.first!

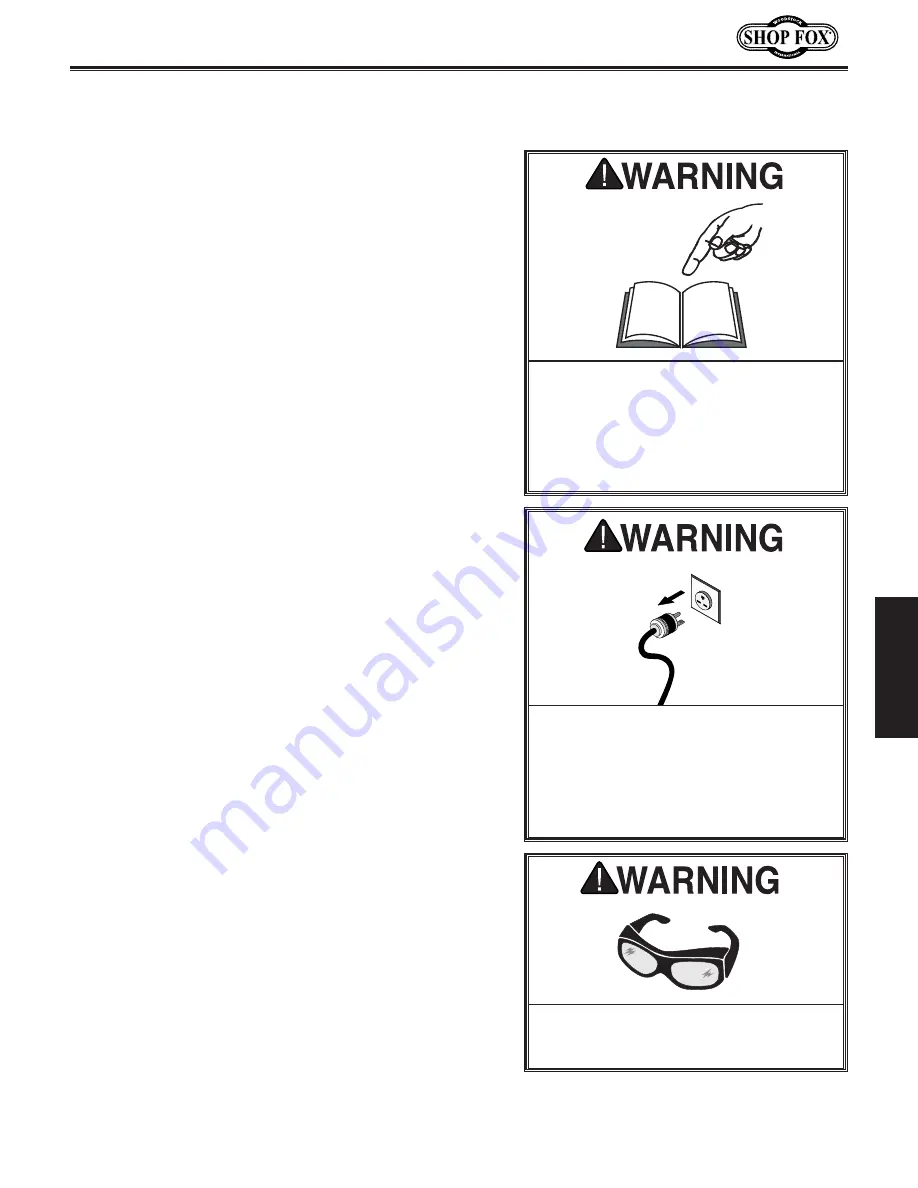

Always.wear.safety.glasses.when.oper-

ating.this.machine..Failure.to.comply.

may.result.in.serious.personal.injury.

DO.NOT.investigate.problems.or.adjust.

the.machine.while.it.is.running..Wait.

until. the. machine. is. turned.

OFF

,.

unplugged. and. all. working. parts.

have.come.to.a.complete.stop.before.

proceeding!

READ. and. understand. this. entire.

instruction. manual. before. using. this.

machine..Serious.personal.injury.may.

occur. if. safety. and. operational. infor-

mation.is.not.understood.and.followed..

DO.NOT.risk.your.safety.by.not.reading!

Basic.Use.and.Care

Power feeders reduce kickback hazards and improve

cutting results by feeding in a consistent and stable

manner. Remember, do not to stand in the path of

potential kickback. When not in use, support the power

feeder with a wooden block so the rubber wheels are

raised above the table and do not compress from the

weight of the power feeder.

The lock levers and handcranks allow you to adjust the

power feeder tracking and height to accommodate many

workpiece sizes. Before loosening any lock lever, always

support the power feeder with a block of wood, so the

power feeder does not drop and cause damage.

Adjust the power feeder so it is toed-in approximately

1° to 1.5° degrees towards the machine fence. This

adjustment will ensure the power feeder wheels slightly

push the workpiece against the fence during cutting

operations (see

Figure.8.

on

.Page.14

). A featherboard

may be used on the infeed side to help feed long or large

stock.

Next, adjust the power feeder so the rubber wheels are

parallel with the table surface, and are

1

⁄

8

" lower than

the thickness of your workpiece. This adjustment ensures

that the workpiece will not slip or hang in the middle of

a cut. Always double check that the power feeder wheels

are slightly lower than the workpiece before you begin

feeding operations. Otherwise, the workpiece may slip

and kickback.