ADJUSTMENTS

-22-

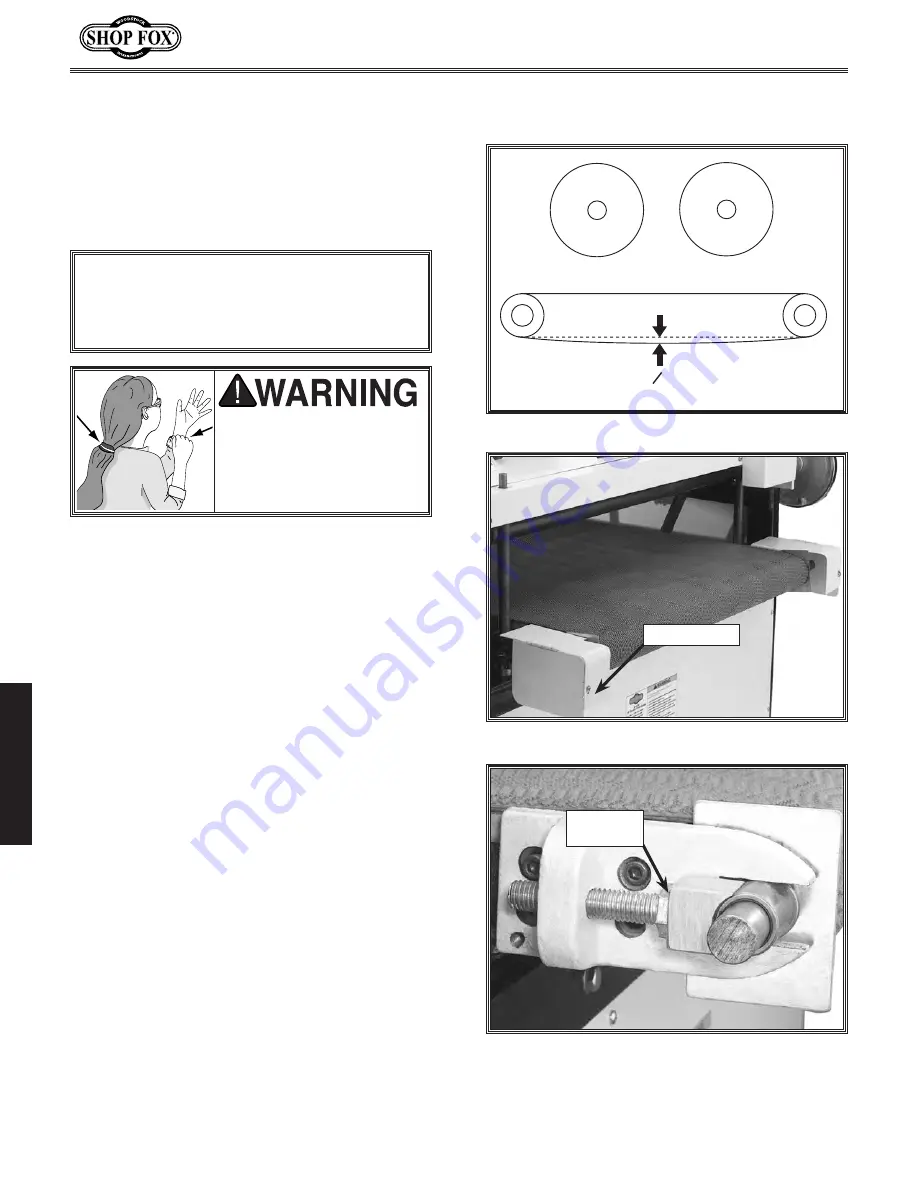

Conveyor Belt

For this adjustment, you will adjust the feed

conveyor belt hanging gap and the tracking, so the

conveyor runs in the center of the table and the

drive roller does not slip at maximum sanding

load. See

Figure 39

.

To adjust the feed conveyor belt tension and

tracking, do these steps:

1.

Remove the screws from the feed conveyor

safety covers and open the covers. See

Figure

40

.

2.

Locate the conveyor roller adjustment bolts

at the infeed roller. See

Figure 41

.

• If the feed conveyor belt is loose, turn both

conveyor roller adjustment bolts counter-

clockwise the same amount until the belt

hangs with a

1

⁄

2

" gap.

• If the feed conveyor belt tracks to the right,

start the conveyor and slightly turn the

right-side conveyor roller adjustment bolt

counter-clockwise.

• If the feed conveyor belt tracks to the left,

start the conveyor and slightly turn the left-

side conveyor roller adjustment bolt

counter-clockwise.

3.

Close the safety covers and run the feed conveyor

for 15 minutes at the fastest setting to make sure

the belt tracks in the center of the table.

4.

Repeat

Steps

2

and

3

until the belt tracks in

the center of the table.

5.

Turn the feed conveyor

OFF

and install the

safety cover screws.

2"

1

Figure 39.

Conveyor belt hanging gap.

NOTICE

ONLY

make adjustments to the infeed roller side

so the drive-chain tension is not affected.

Make sure loose clothing

and long hair is secured

and kept away from all

moving parts.

Figure 41.

Conveyor roller adjustment bolts.

Figure 40.

Infeed-conveyor safety covers.

Cover Screws

Adjustment

Hex

Summary of Contents for SHOP FOX W1678

Page 48: ...NOTES...

Page 49: ......