17

9. Control Mode and Output Limiting Function

This instrument has various (voltage, current, power, and voltage square) feedback control modes.

Feedback control functions to detect the output voltage or output current of the power regulator, and control it to an output value proportional

to the control input.

As a result, the instrument can maintain a stable output with a little fluctuation even if the supply voltage or load resistance changes.

As for the output limiting function, current limiting and start-up time output limiting are available.

It should be noted that rectifier type measuring instruments, if used to measure the output voltage or output current of the instrument, cannot

display a correct value.

Always use an effective value type measuring instrument.

9-1. Phase control and voltage feedback

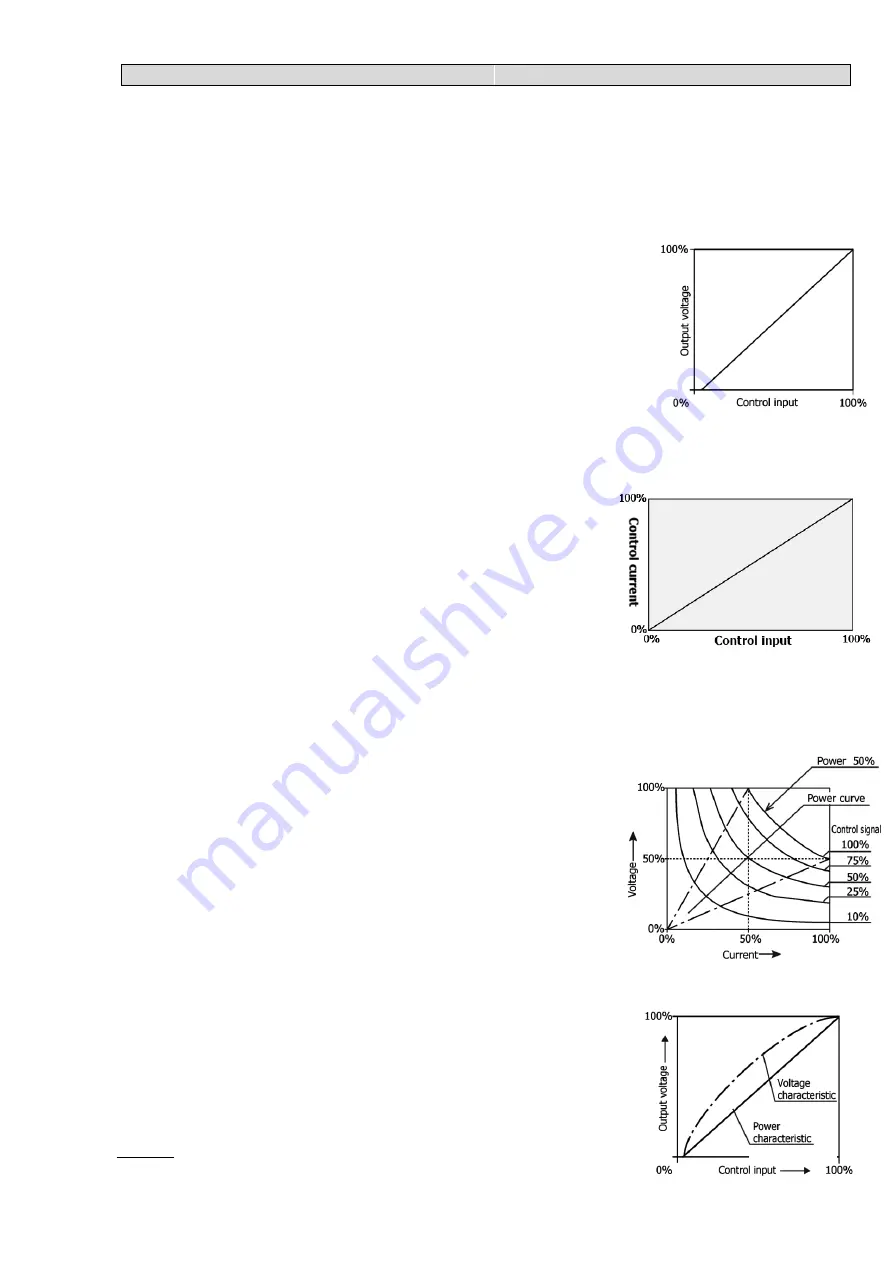

Voltage feedback control controls output so that the output voltage is proportional to the control input.

When the control input is constant, the output voltage is controlled to a constant level even if the

load or power supply fluctuates.

For example, if the supply voltage is 200 V and the control input is 80%, the output voltage is

controlled to 160 V.

As shown in the characteristic diagram on the right, voltage feedback has a characteristic that

control input and output voltage work in a linear fashion.

Since output is controlled by a voltage controller, even if the primary voltage fluctuates, the

secondary voltage fluctuates very little and is 2% or less of the fluctuation width of the primary side

(that is, 0.2 V or less in comparison with the fluctuation 10 V on the primary side), which is

appropriate for precision control.

Under voltage feedback control, the average of three

phase load voltage is controlled.

It is not possible to individually control each phase voltage.

9-2. Phase control and current feedback

Current feedback control controls output so that the output current is proportional to the

control input.

When the control input is constant, the output current is controlled to a constant level even

if the load or power supply fluctuates.

For example, if the current capacity is 100 A and the control input is 80%, the output current

is controlled to 80 A.

This control characteristic is based on an operation performed using the current setting

value given by the control signal and the current signal received from a current transformer

(built-in CT) and, assuming that control input is constant, current is controlled at a constant

level even if the load and power fluctuate.

Accordingly, this control is suitable for controlling platinum, molybdenum, tungsten, Kanthal

Super, and other heating elements.

With this constant current control, the instrument works effectively for the following heaters:

䕕

Heaters in which rush current flows

: Platinum, molybdenum, tungsten, and

Kanthal Super

䕕

Heaters in which current changes significantly

: Carbon, salt bath

䕕

Stability of electrolysis current

: Plated

Under current feedback control, the average of three phase load current is controlled.

It is not possible to individually control each phase current.

9-3. Phase control and power feedback

Power feedback control controls output so that the product of the output voltage and output

current is proportional to the control input. When the control input is constant, the output power

is controlled to a constant level even if the load or power supply fluctuates. For example, if the

supply voltage is 200 V, the current capacity is 100 A, and the control input is 80%, the output

power is controlled to the following value:

䌮

䌮

3 x 200V x 100A / 2 x 0.80

䍦

13.9 (kVA)

In this control mode, power is half of the thyristor rating.

As shown in the diagram on the right, this is represented by curves drawn between the points

of 100% voltage x 50% current and 50% voltage x 100% current, which means that power at

50% of the thyristor rating is controlled.

In other words, even a thyristor with a rating of 200 V/100 A can control 17.3 kVA power.

Under power feedback control, the power consumption of load (Total power of three phase:

䌮

3 x Average of three phase load voltage

values x Average of three phase load current values) is controlled. It is not possible to individually control each phase power.

9-4. Phase control and voltage square feedback

Voltage square feedback control controls output so that the square of output voltage is proportional

to the control input. For loads with low temperature characteristics such as a

nichrome

heater, this

improves the control efficiency because the control signal is proportional to the output power.

䕕

The control signal and the output power have a linear relationship for improved control efficiency.

䕕

In manual adjustment, the power in % can be adjusted according to the graduation of the regulator.

䕕

Power equation

P = V x I

P = V x V/R

䊹

Constant… (Explanation: P is proportional to V

2

.)

䍈

P

䌱

V

2

[P: Power, V: Voltage, I: Current, R: Resistance]

Under voltage square feedback control, the square of the average of three phase load voltage values is controlled. It is

not possible to individually control each phase.

Power characteristic