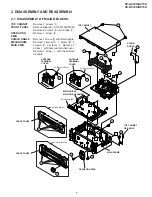

2

VC-A412U/A413U

VC-H812U/H813U

IMPORTANT SERVICE NOTES

WARNING : TO REDUCE THE RISK OF FIRE OR ELEC-

TRIC SHOCK, DO NOT EXPOSE THIS AP-

PLIANCE TO RAIN OR MOISTURE.

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK. DO

NOT REMOVE COVER. NO USER-SERVICEABLE

PARTS INSIDE. REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

This symbol warns the user of uninsulated voltage

within the unit that can cause dangerous electric shocks.

This symbol alerts the user that there are important

operating and maintenance instructions in the literature

accompanying this unit.

This symbol mark means fast operating fuse.

For continued protection against risk of fire, replace

only with same type fuse F901 (3.0A, 125V).

CAUTION:

BEFORE RETURNING THE VIDEO CASSETTE

RECORDER

Before returning the video cassette recorder to the user,

perform the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the video cassette

recorder.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields, isola-

tion resistor/capacitor networks, mechanical insula-

tors etc.

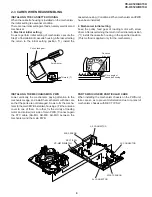

3. To be sure that no shock hazard exists, check for

current in the following manner.

●

Plug the AC line cord directly into a 120 volt AC outlet

(Do not use an isolation transformer for this test).

●

Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15

µ

F capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as a water pipe or conduit.

●

Use an SSVM or VOM with 1000 ohm per volt, or

higher, sensitivity or measure the AC voltage drop

across the resistor (See Diagram).

●

Move the resistor connection to earth exposed metal

part having a return path to the chassis (antenna,

metal cabinet, screw heads, knobs and control shafts,

SSVM

AC SCALE

1.5k ohms.

10W

CONNECT TO

KNOWN EARTH

GROUND

TO EXPOSED

METAL PARTS

0.15 µF

TEST PROBE

etc.) and measure the AC voltage drop across the

resistor. Reverse the AC plug on the set and repeat

AC voltage measurements for each exposed part.

Any reading of 0.45V rms (this corresponds to 0.3mA

rms AC.) or more is excessive and indicates a poten-

tial shock hazard which must be corrected before

returning the video cassette recorder to the owner.

3.0A 125V