R-450H

25

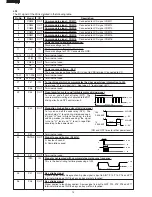

SCHEMATIC

NOTE: CONDITION OF OVEN

1. DOOR CLOSED.

2. CLOCK APPEARS ON DISPLAY.

NOTE: " " indicates components with potentials above 250V.

Figure O-1. Oven Schematic-OFF Condition

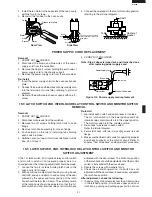

SCHEMATIC

NOTE: CONDITION OF OVEN

1. DOOR CLOSED.

2. COOKING TIME PROGRAMMED.

3. START KEY TOUCHED.

Figure O-2. Oven Schematic-Cooking Condition

POWER TRANSFORMER

MAGNETRON

H.V. RECTIFIER

H. V. FUSE

0.75A

CAPACITOR

1.13

µ

AC2300V

TURNTABLE MOTOR

FAN MOTOR

OVEN LAMP

2ND. INTERLOCK

RELAY CONTROL

SWITCH

MONITOR SWITCH

CONTROL

UNIT

1ST. LATCH

SWITCH

B1

B2

A2

OL

FM

TTM

N.O.

RY-1

COM.

A1

THERMAL

CUT-OUT

145˚C (OVEN)

THERMAL

CUT-OUT 145˚C

(MAGNETRON)

RY-2

EARTH

BLU

BRN

230-240V/50Hz

G-Y

FUSE

F10A

N

L

LINE CROSS CAPACITOR

0.068

µ

/AC250V

NOISE SUPPRESSION COIL

LINE BYPASS

CAPACITOR

0.0022

µ

/AC250V

LINE BYPASS

CAPACITOR

0.0022

µ

/AC250V

2ND.

INTERLOCK

RELAY

COM.

N.O.

NOISE FILTER

EARTH

BLU

BRN

230-240V/50Hz

G-Y

FUSE

F10A

N

L

LINE CROSS CAPACITOR

0.068

µ

/AC250V

NOISE SUPPRESSION COIL

LINE BYPASS

CAPACITOR

0.0022

µ

/AC250V

LINE BYPASS

CAPACITOR

0.0022

µ

/AC250V

POWER TRANSFORMER

MAGNETRON

H.V. RECTIFIER

H. V. FUSE

0.75A

CAPACITOR

1.13

µ

AC2300V

TURNTABLE MOTOR

FAN MOTOR

OVEN LAMP

1ST. LATCH

SWITCH

B1

B2

A2

OL

FM

TTM

N.O.

RY-1

COM.

A1

THERMAL

CUT-OUT

145˚C (OVEN)

2ND. INTERLOCK

RELAY CONTROL

SWITCH

CONTROL

UNIT

COM.

N.O.

THERMAL

CUT-OUT 145˚C

(MAGNETRON)

NOISE FILTER

RY-2

2ND.

INTERLOCK

RELAY

MONITOR SWITCH

Summary of Contents for R-450H

Page 2: ...36 R 450H ...