ADJUSTMENTS 10 - 8

b. SPF original off-center adjustment (SIM50-12)

Note:Before performing this adjustment, be sure to check that the paper

off center is properly adjusted.

1) Make a test chart for the center position adjustment and set it on the

SPF.

<Adjustment specification>

Draw a line on a paper in the scanning direction.

2) Make a normal copy from the bypass tray, and compare the copy

and the original test chart.

If necessary, perform the following adjustment procedures.

3) Execute SIM 50-12.

4) After warm-up, shading is performed and the current set value of the

off center adjustment at each paper feed port is displayed on the

display section in 2 digits.

5) Enter the set value and press the [START] key.

The set value is stored and a copy is made.

<Adjustment specification>

(8) SPF white correction pixel position adjustment(SIM63-7)

(required in an SPF model when replacing the lens unit)

1) Fully open the SPF.

2) Execute SIM 63-7.

If the value is 93 - 229, it is displayed on the display and written into

the EEPROM.

If the value is 0 - 92 or 230 - 999, it is displayed on the display but not

written into the EEPROM.

If the value is 1000 or above, "--" is displayed on the display and it is

not written into the EEPROM.

•When the display is 0:

Check that the SPF is open.

Check that the lamp is ON.(If the lamp is OFF,check the MCU

connector.)

Check that the CCD harness is properly inserted into the MCU

connector.

•When the display is 281 or above:

1) Remove the table glass.

2) Remove the dark box.

3) Slide the lens unit toward the front side and attach it,then execute

SIM.

•When the display is 143 or below:

1) Remove the table glass.

2) Remove the dark box.

3) Slide the lens unit toward the rear side and attach it,then execute

SIM.

*

When the lens unit is moved,execute the OC main scanning

magnification ratio auto adjustment,SIM 48-1-1,SIM48-3 and the PF

original off-center adjustment.

*

This adjustment is basically O.K.with SIM 63-7.

B.Image density adjustment

(1)Copy mode (SIM 46-1)

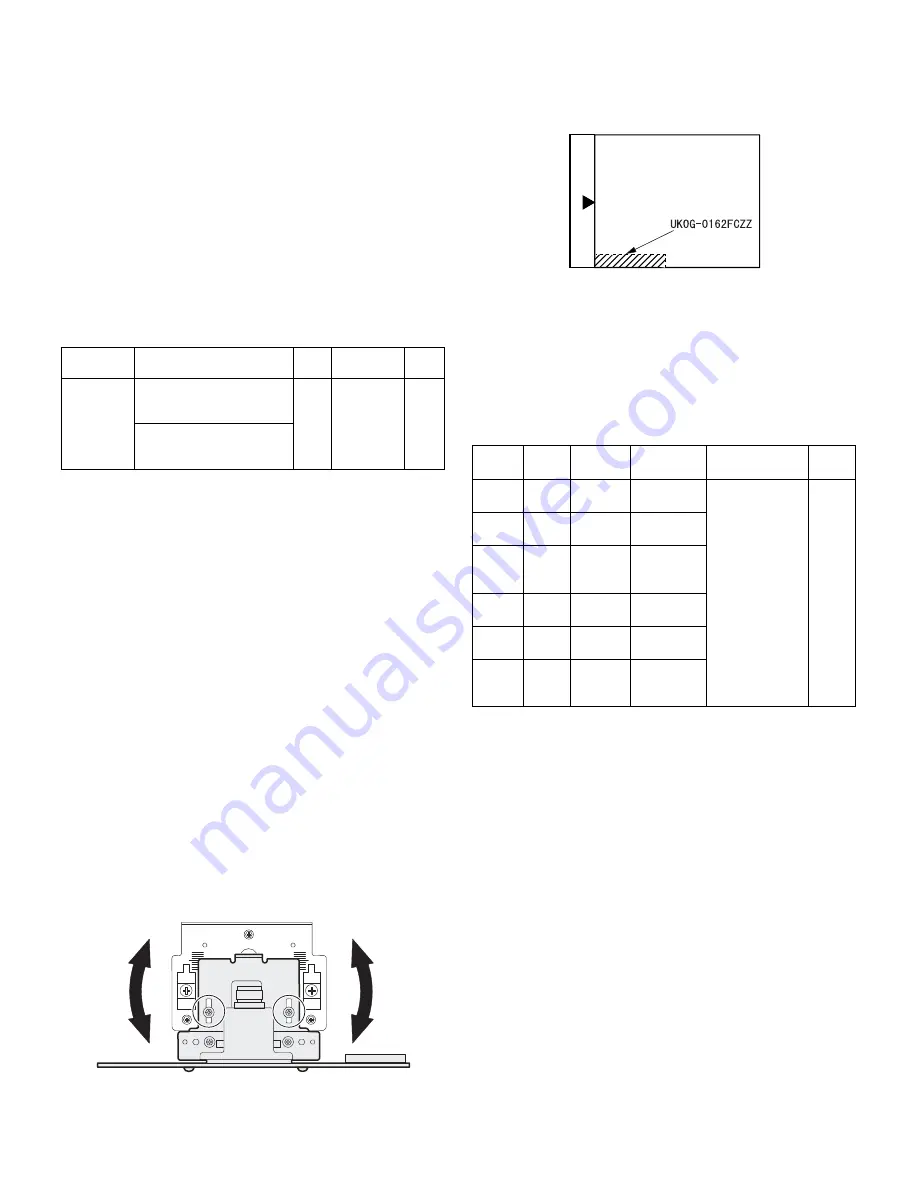

1)Set a test chart (UKOG-0162FCZZ) on the OC table as shown below.

2) Put several sheets of A3 or 11" x 17" white paper on the test chart.

3) Execute SIM 46-1.

4) After warm-up, shading is performed and the current set value of the

density level is displayed on the display section in 2 digits.

For mode selection, use the AUTO/TEXT/PHOTO key.

5) Change the set value with the Numeric keys to adjust the copy

image density.

6) Make a copy and check that the specification below is satisfied.

<Adjustment specification>

Mode

Specification

SIM

Set value

Set

range

Original off

center

mode

(SPF mode)

Single:

Center ±3.0mm(TEXT

indicator)

SIM

50-12

Add 1:

0.1mm shift

to R side

Reduce 1:

0.1mm shift

to L side

1 ~ 99

Duplex:

Center ±3.5mm(PHOTO

indicator)

R

F

Density

mode

LED

Exposure

level

Sharp Gray

Chart output

Set value

Set

range

Auto

Auto

-

"2" is slightly

copied.

The greater the

set value is the

greater the

density is The

smaller the set

value is the

smaller the

density is.

1 ~ 99

Text

Text

3

"3" is slightly

copied.

Photo

(Error

diffusion)

Photo

3

"2" is slightly

copied.

Toner

save

Auto/

Photo

-

"2" is slightly

copied

Toner

save

Text/

Photo

3

"3" is slightly

copied

Photo

(Dither)

Auto/

Text/

Photo

3

"2" is slightly

copied