MX-5141FN MX-4140N/4141N/5140N/5141N (MAIN UNIT) 2 – 6

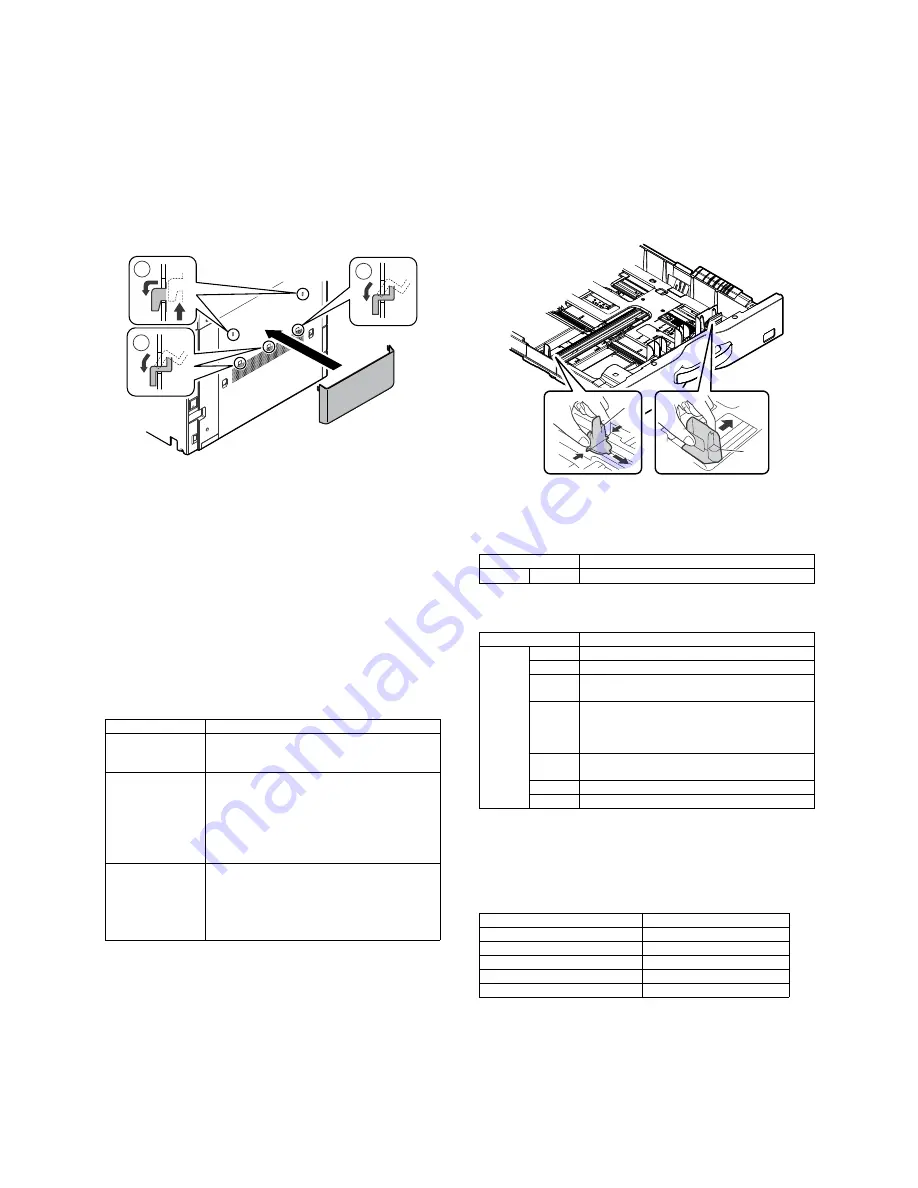

F. Installation of the operation manual pocket

1)

Install the Operation Manual storage (Packed items) cover to

the left side of the machine.

a)

First, insert the pawl on the lower side of the Operation

Manual pocket.

b)

Then, lift the pawl on the upper side and insert it, and slide

down to install.

* If the FINISHER is installed together with installation of the

machine, the Operation Manual storage cover must be

installed to the FINISHER.

G. Tray setup

(1)

Simulation setup

Change the tray setting in the "system setting" mode. If "Disabling

of Tray Settings" has been enabled in the system settings (adminis-

trator), the tray settings (except for the bypass tray) cannot be con-

figured.

1)

Enter the SYSTEM SETTING mode.

2)

Touch the [Paper Tray Settings] key.

3)

Touch the [Paper Tray Settings] key to configure the settings.

These settings specify the paper type, paper size, and func-

tions allowed for each paper tray. When the [Tray Settings] key

is touched, a list appears showing the trays and the current

settings.

4)

Touch the [Change] key in the above screen to change the set-

tings. The following settings can be configured.

(2)

Tray size setup

1)

Pull out the paper tray.

Gently pull the tray out until it stops.

If paper remains in the tray, remove it.

2)

Adjust the guide plates A and B by squeezing their lock levers

and sliding them to match the vertical and horizontal dimen-

sions of the paper to be loaded.

The guide plates A and B are slidable. Slide each guide plate

while squeezing its lock lever.

H. Specifications setup

Used to set the specifications with SIM26 according to the cus-

tomer's request.

To customize the following items after completion of the destination

setup, change the set values.

I.

Image quality check

(1)

Image loss, void area, image off-center check

Make a copy in the original table mode and in the RSPF/DSPF

mode. Check to confirm that the image loss and the void area are

in the range shown below.

Item

Description

Type

Select the type of paper that is loaded in the tray.

The paper types that can be selected vary by paper

tray.

Size

Select the paper size from the list. The paper sizes

that can be selected vary by tray. The sizes that

can be selected may also be restricted by the paper

type selected above.

If the desired size does not appear in the list, select

[Custom Size] and directly enter the size (only for

the bypass tray).

Feeding Approved

Job

Select the modes that can be used. If there is a

function that you do not wish to be used with the

selected tray, disable the function. When the "Type"

is other than plain paper, recycled paper, colored

paper, or a user type, [Fax] and [Internet Fax]

cannot be selected.

1

1

2

SIM No

Content

26

6

Used to set the destination.

SIM No

Content

26

2

LCC paper size setting

3

Used to set the auditor specification mode.

5

Used to set the count mode of the total counter and

the maintenance counter.

18

Used to set YES/NO of the toner save mode (Only

in UK and Japan versions)

* For other destination versions, this setup is

made by the user program.

52

Used to set YES/NO of counting when non-print

paper is passed through each counter.

53

Used to set YES/NO of user calibration permission.

65

Used to set the limit number of sheets for stapling.

Content

Standard adjustment value

Lead edge void area

3.0

1.0mm

Rear edge void area

2.0 - 5.0mm

FRONT/REAR void area

2.0

2.0mm

Lead edge image loss adjustment

3.0

1.0mm

Side image loss adjustment

2.0

1.0mm

A

B