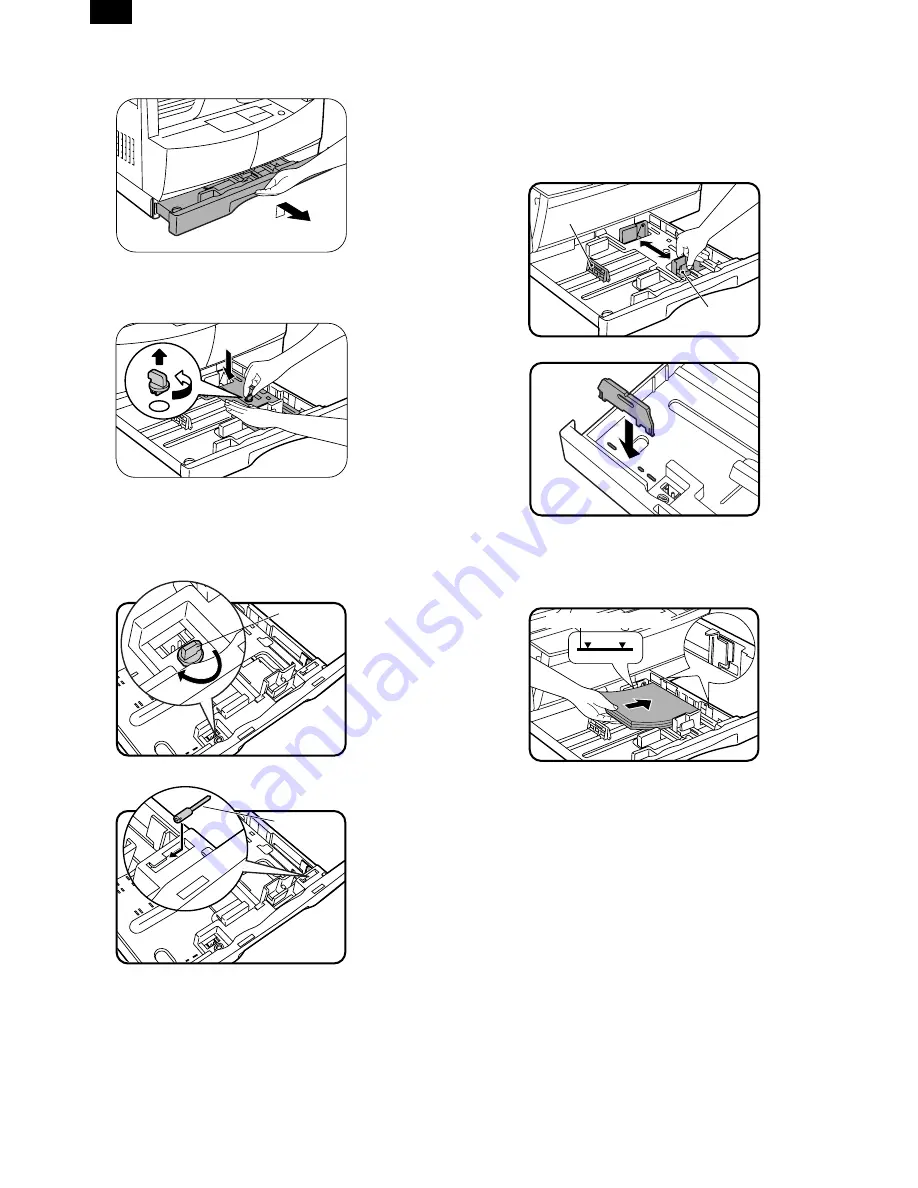

11) Raise the handle of the paper tray and pull the paper tray out

until it stops.

12) Remove the pressure plate lock. Rotate the pressure plate lock

in the direction of the arrow to remove it while pressing down the

pressure plate of the paper tray.

13) Store the pressure plate lock which has been removed in step 5

and the screw which has been removed in step 2 in the front of

the paper tray.

•

To store the pressure plate lock, rotate the lock to fix it on the

relevant location.

14) Push the pressure plate down until it locks in place.

15) Squeeze the lock lever of the front guide and slide the front

guide to match the width of the paper.

16) Move the left guide to the appropriate slot as marked on the

tray.

•

When using 11"

×

17" copy paper, store the left guide in the

slot at the left front of the paper tray.

17) Load copy paper into the tray.

•

Set the paper along the guides.

•

The tray holds up to 250 sheets of about 9kg bond paper.

Do not load paper above the maximum height line.

18) Push the paper tray firmly back into the copier.

19) Ensure that the power switch of the copier is in the OFF position.

Insert the supplied power cord into the power cord socket at the

rear of the copier.

•

If you use the copier in a country other than the country

where the copier was purchased, you will need to make sure

that your local power supply is compatible with your model. If

you plug the copier into an incompatible power supply, ir-

reparable damage to the copier will result.

20) Plug the other end of the power cord into the nearest outlet.

•

Only insert the power cord into a properly grounded wall

socket.

Do not use extension cords or power strips.

Pressure

plate

lock

Screw

Front guide

Left guide

Maximum height line

AL-1610

AL-1600/1610 FM/E [5] UNPACKING AND INSTALLATION 11/27/1998

5 – 2