SHARK SC-2412 • 97-6267 • REV. 3/04

A

U

T

OMA

TIC P

A

R

TS

W

ASHER Maintenance Guide

20

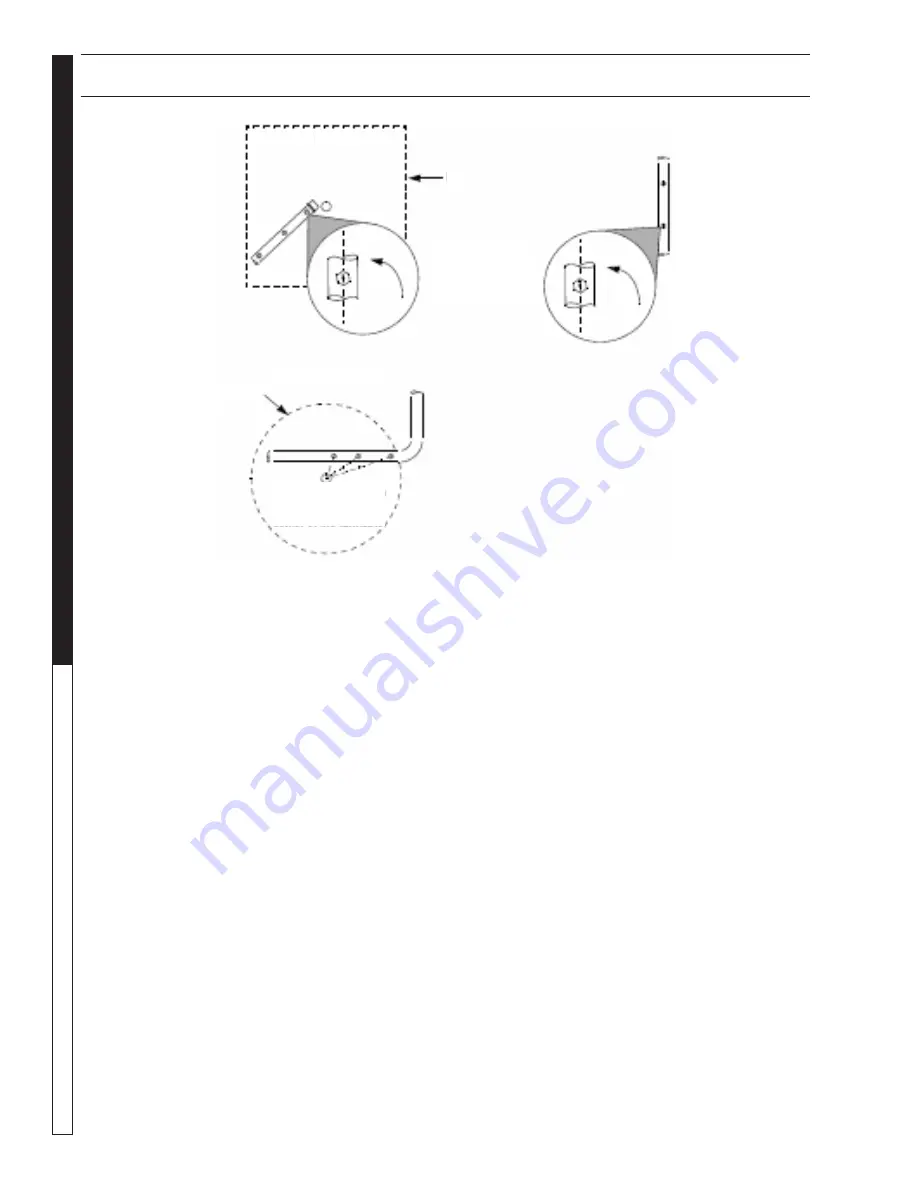

Cleaning and Aligning the Spray Nozzles

To ensure optimum cleaning performance, it is impor-

tant that you examine the spray nozzles periodically and

clean and align them if necessary.

To clean a plugged nozzle, remove it from the spray

pipe and use a small wire brush to free the nozzle of

any obstructions. When you replace the nozzle on the

spray pipe, make sure you align it according to Figure

Above to maintain a proper spray pattern.

Note: The spray nozzles are sized and positioned to

optimize the distribution of cleaning solution in the wash

chamber. If you remove the nozzles make sure you re-

place them in the correct position on the appropriate

pipe. Spray nozzle specifications are stamped on the

face of each nozzle, as shown above.

Cleaning out the Sump

Step 1:

Remove oil from the cleaning solution using the DOS

System (See

Using the DOS System).

Step 2:

Remove the debris screen.

Step 3:

Drain the wash solution from the sump chamber. To drain

the solution either use the sump drain or a small sub-

mersible pump.

Section 5: Maintenance and Repair

TOP NOZZLES

SIDE NOZZLES

Align the notch in

each spray nozzle

with the center of the

turntable

Rotate each nozzle

approximately 3°

from the centerline of

the pipe

BOTTOM NOZZLES

Turntable

SIDE NOZZLES

Note: Manufacturer recommends that you reuse the

wash solution. To do so, transfer it to a suitable holding

container (such as a 55-gallon drum) while you clean

out the sump chamber.

Step 4:

Remove sand and other debris from the bottom of the

sump chamber. To remove the debris either flush it out

through the sump drain, or vacuum it out using a wet/

dry vac. Dispose of the debris in accordance with appli-

cable local, state, and federal regulations.

Note: Take special care to ensure that the heating ele-

ment and the low-water float are free of debris. A build

up of debris around the heating element will decrease

heating performance and may cause the element to

overheat and fail. A build up of debris around the float

may cause the low water shut-off system to malfunc-

tion (See

Low Water Shutoff System)

Step 5:

Transfer the wash solution back to the sump chamber,

and add fresh water if necessary.

Step 6:

Replace the debris screen.

Step 7:

Heat the wash water to operating temperature, then add

appropriate amount of factory detergent.

Step 8:

Run the machine through a 15-minute wash cycle.

3°

3°

Lid