9.800-085.0 • 8.919-015.0 • Rev. 01/11

PRESSURE

W

ASHER

T

roub

leshooting Guide

10

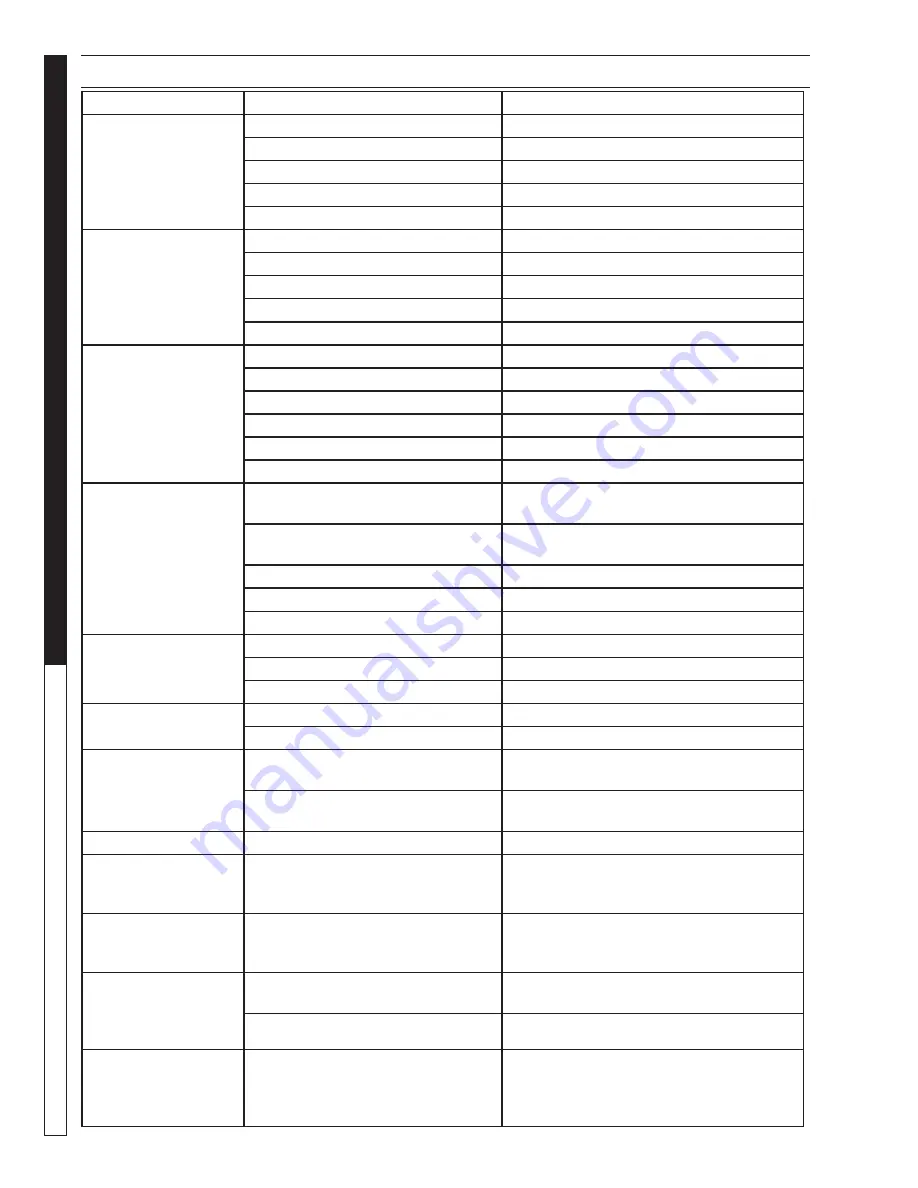

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

PUMP RUNNING

NORMALLY BUT

PRESSURE LOW ON

INSTALLATION

Pump sucking air

Check water supply and possibility of air.

Check valves sticking

Check and clean or replace if necessary.

Unloader valve seat faulty

Check and replace if necessary.

Nozzle incorrectly sized

Check and replace if necessary.

Worn piston packing

Check and replace if necessary.

FLUCTUATING PRES-

SURE

Valves worn

Check and replace if necessary.

Blockage in valve

Check and replace if necessary.

Pump sucking air

Check water supply connections.

Worn piston packing

Check and replace if necessary.

Insuffi cient water

Check fi lter and hose for breakage.

PRESSURE LOW

AFTER PERIOD OF

NORMAL USE

Nozzle worn

Check and replace if necessary.

Suction or delivery valves worn

Check and replace if necessary.

Suction or delivery lines blocked

Check and clean if necessary.

Unloader valve seat worn

Check and replace if necessary.

Worn piston packing

Check and replace if necessary.

Water temperature excessive

Reduce to below 160° F.

PUMP NOISY

Air in suction line

Check water supply and connections on suc-

tion line.

Broken or weak suction or delivery valve

spring

Check and replace if necessary.

Foreign matter in valves

Check and clean if necessary.

Worn bearings

Check and replace if necessary.

Excessive temperature of water

Reduce to below 160° F.

PRESENCE OF

WATER IN

PUMP OIL

Oil seal worn

Check and replace if necessary.

High humidity in air

Check and replace if necessary.

Piston packing worn

Check and replace if necessary.

WATER DRIPPING

FROM UNDER PUMP

Piston packing worn

Check and replace if necessary.

O-ring plunger retainer worn

Check and replace if necessary.

WATER DRIPPING

FROM PUMP

PROTECTOR

Water supply pressure too high (over

90 PSI)

Lower water supply pressure using a regula-

tor.

Spray gun is in the off position for over

5 minutes

Turn machine off if not in use for over 5 min-

utes.

OIL DRIPPING

Oil seal worn

Check and replace if necessary.

EXCESSIVE

VIBRATION IN HIGH

PRESSURE HOSE

Irregular functioning of the pump

valves

Check and replace if necessary.

MOTOR DOES

NOT START WHEN

SWITCHED ON

Plug not well connected or lack of power

supply

Check plug, cable and switch.

WHEN SWITCHING

ON THE MACHINE,

MOTOR HUMS BUT

DOES NOT RUN

Main voltage is insuffi cient lower than

the minimum required

Check to make sure main power supply is

adequate.

The pump is stuck or frozen

Check by turning the motor manually.

MOTOR STOPS

Tripped thermal overload due to over-

heating

Check that main voltage corresponds to the

specifi cations. Wait a few minutes before turn-

ing on the machine again by resetting the GFCI

cord.