PAGE 15

PAGE 14

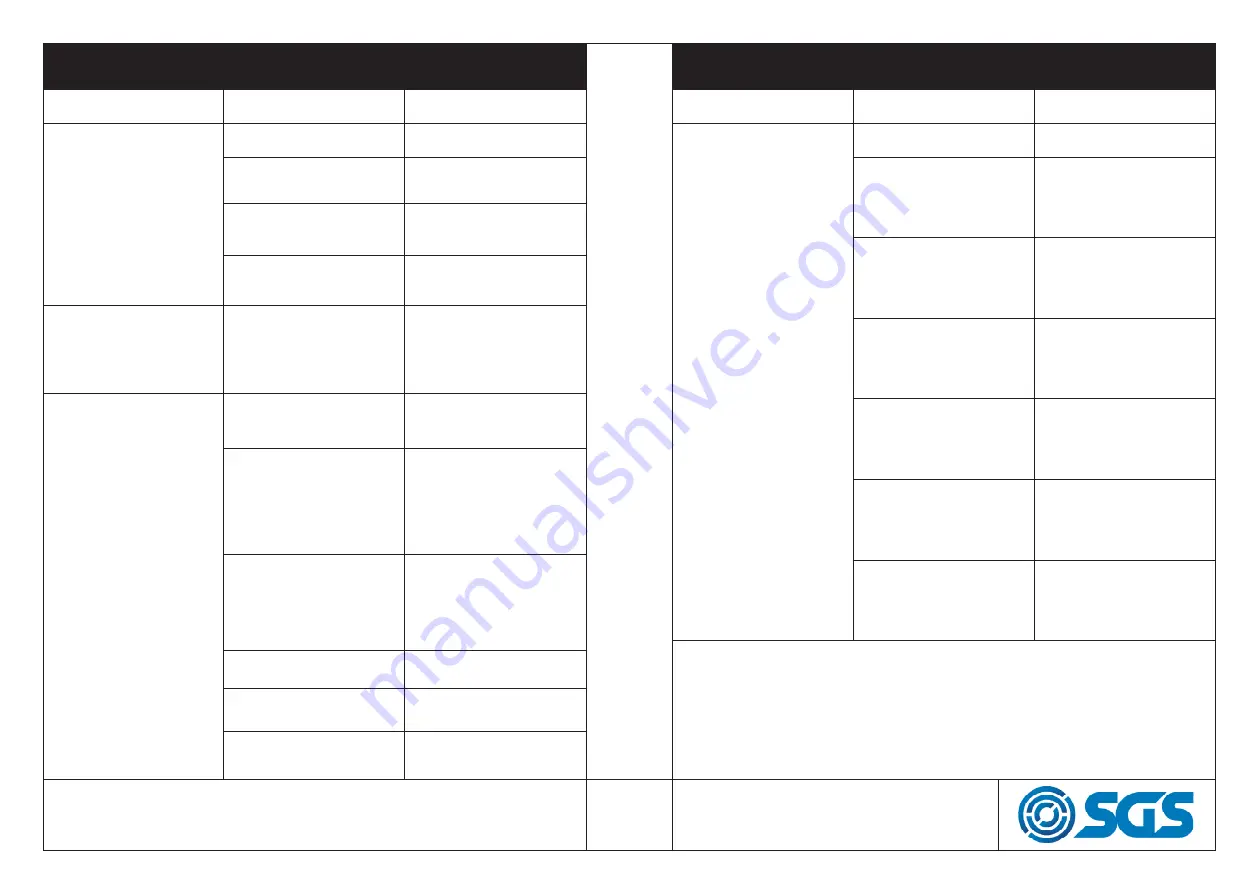

TROUBLESHOOTING

STORAGE & HANDLING

PROBLEM

CAUSE

SOLUTION

Engine fails to start

Lack of fuel in tank.

Fill tank as necessary.

No fuel reaching carbu-

retor.

Fuel cock isolated. Turn

on fuel shut-off valve.

Engine switch is in the

OFF position.

Set engine switch to the

ON position.

Lack of spark at the

spark plug.

Lack of spark at the

spark plug.

Engine stops and will

not restart

Lack of oil in engine

causing ‘Low Oil Pro-

tection’ sensor to stop

engine from running.

Fill oil reservoir as neces-

sary.

Pump fails to prime

Priming chamber not

filled correctly.

Fill priming chamber

leaving no air gap.

Air leaks through the

suction line joints (dam-

aged hose, broken hose

clamps, broken / ill-

fitting gasket).

Carry out repairs as

necessary/check, repair

connections as required.

Blocked inlet hose.

Clean strainer & ensure

it is not submerged in

mud or sediment etc.

Ensure there are no kinks

in delivery hose.

Engine speed too low.

Increase engine speed.

Damaged impeller.

Renew impeller after

dismantling pump.

Air leaks through dam-

aged seal.

Renew seal.

PROBLEM

CAUSE

SOLUTION

Low output from pump

Engine speed too low

Increase engine speed.

Impeller clogged

Clean strainer and en-

sure it is not submerged

in mud or sediment etc.

Suction or delivery line

obstructed

Remove obstruction and

ensure there are no kinks

in delivery line.

High friction losses in

the suction line

Avoid un-necessary

curves, restrictions or

valves.

Suction lift too high

Set pump as close as

possible to the level of

the liquid to be pumped.

Congested material

inside pump

Dismantle pump & clean

out.

Damaged impeller

Dismantle pump and

renew impeller.

WWW.SGS-ENGINEERING.COM