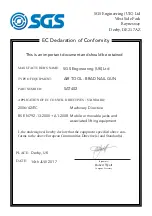

EC Declaration of Conformity

This is an important document and should be retained

MANUFACTURER’S NAME:

TYPE OF EQUIPMENT:

PART NUMBER:

I, the undersigned, hereby declare that the equipment specified above con

-

forms to the above European Communities Directive(s) and Standard(s).

PLACE:

DATE:

(Signature)

Robert Wyatt

Company Secretary

Derby, UK

14th JULY 2017

SGS Engineering (UK) Ltd

SGS Engineering (UK) Ltd

West Side Park

Raynesway

Derby, DE21 7AZ

AIR TOOL - BRAD NAIL GUN

SAT402

2006/42/EC

Machinery

Directive

BS EN 792-13:2000 + A1:2008 Mobile or movable jacks and

associated

lifting

equipment

APPLICATION OF EC

COUNCIL DIRECTIVES / STANDARD: