EXTRACTION MODE SETUP

Remove water quickly and effectively from flooded

structures.

1) Connect vacuum hose to vacuum inlet.

2) Connect one or two power cords depending on

job requirements. The second cord must be

connected to a separate 15 amp circuit.

NOTICE:

The power cords of the HVE3000 should be

plugged into separate GFCI-protected 115 volt outlets

rated for at least 15

amps. Always plug the cord firmly

into the base of the unit first and secure the cord into the

cord clip.

NOTICE:

Connect to two separate 15A circuits ONLY. A

bright green light indicates correct connections. No light

will show when using only one cord.

3) For automatic pumpout,

connect hose to pumpout

outlet to pump outlet and turn pump switch ON.

Do not

use anything smaller than a

⅝ in. hose, and ensure

there are no kinks in the hose.

For increased pumpout

performance, see “Maximizing Pumpout Performance,”

p. 5.

NOTICE:

Before turning the pump on, attach a drain

hose and place the end into a sink, toilet, or other

suitable drain. Operating the pump without a drain hose

in place may cause injury.

NOTICE:

Avoid contact with water draining from the

pump outlet. Water is pressurized and may exit the unit

with force. Water may contain chemicals or

contaminants that can be a health hazard upon contact.

4) Turn on vacuum blower(s) to LOW, MED or HIGH.

The machine can operate with either one or both

blowers running. For maximum vacuum performance,

turn on both Blower 1 and Blower 2.

For use as truckmount extraction booster, see

“Booster Mode” below.

NOTICE: Keep truckmount outlet capped when not

in use.

EXTRACTION OPERATION TIP

Place the HVE3000 as close as possible to the end of

the hose run nearest the wand or other extraction tool.

This position will maximize the vacuum boost provided

by the unit.

Airflow shut-off

If the blowers emit a high-pitched whine and there is no

vacuum generated, it most likely means that the ball

float has engaged and that the tank is full and needs to

be emptied, or that excessive foam is present. When

this occurs, check the tank and empty it if necessary,

and use a defoamer any time foam is present.

TRUCKMOUNT BOOSTER SETUP

NOTICE:

Do not attempt to operate the unit with a

truckmount producing vacuum pressures greater than

12 in. Hg (164 in. H

2

O). Doing so could damage the unit

and will void the warranty. Be sure to adjust your

truckmount pressure to 12 in. Hg (164 in. H

2

O) or less.

Use in conjunction with a truckmount extractor to provide

additional extraction power.

The HVE3000 has been

tested to boost vacuum on hose runs as long as 300

ft. (90 m). To maximize performance, we recommend

using the shortest runs as possible.

NOTICE:

Do not operate with water temperatures

exceeding 140° F (60° C). Doing so could damage the

unit and will void the warranty.

1) Connect vacuum hose to vacuum inlet.

2) Connect one or two power cords depending on

job requirements.

The second cord must be connected

to a separate 15 amp circuit. A green light indicates the

unit has been correctly connected to separate circuits.

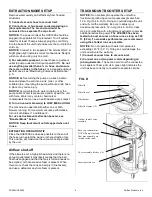

Cover assembly latches (×4)

Recovery tank interior.

NOTE: Pump, float and

float arm assembly are

located inside tank.

Filter lid seal

Airflow shutoff valve

assembly

Filter lid

Filter basket

Filter lid clamps (×2)

Gravity drain hose

FIG. D

SP004 HVE3000

4

Dri-Eaz Products, Inc.