TORQUE LIMITER

Torque limiters are used to drive the crusher mechanism and the input

belt conveyor and act as a safety device to protect against inadvertent

overloads. They are factory preset and should not require field

adjustments.

To ensure proper operation, the friction discs must be kept clean and free

of oil and moisture.

Before presuming torque limiter requires adjustment, check for paper

buildup and other conditions, such as bearing failures and proper belt

alignment.

Should adjustment be required, the following procedure is recommended

o

Tighten hex nut to a “finger tight” position (see fig. 6, page 24)

o

An additional half turn will closely approximate the factory setting

o

An additional 1-2/3 turns will result in the maximum torque setting

o

Should sprocket replacement be necessary, sprocket should be

ground flat and parallel with a surface finish of 65 to 125 micro-

inches

o

With new sprocket installed, provide a five minute run-in period at

minimum torque before final adjustment

18

Summary of Contents for 800-1000 Series

Page 19: ...Figure 1 SHREDDER OPERATION 19 ...

Page 20: ...Figure 2 CHAIN LUBRICATION 20 ...

Page 21: ...Figure 3 REDUCER LUBRICATION PN TA5215H40 21 ...

Page 22: ...Figure 4 CONVEYOR BELT TAKE UP 22 ...

Page 23: ...Figure 5 CHAIN SAG 23 ...

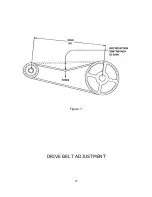

Page 25: ...Figure 7 DRIVE BELT ADJUSTMENT 25 ...

Page 35: ......