12

10-3/16"

11-3/16"

12-3/16"

14-3/8"

x

14-3/8"

6" 7"

8"

11-1/4"

12-1/4"

13-1/4"

A

B

A

B

Section

14-3/8"

x

14-3/8"

14-3/8"

x

14-3/8"

2

2.5

3

3.5

4

4.5

5

5.5

6

34

33

32

31

30

28

26

23

21

29

28.5

28

27

26

24

23

21

18

26

25.5

25

24

23

22

20

18

16

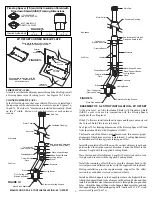

The following steps will assist you in the installation of the Wall

Thimble and of the Wall Support. Figure 11 shows a typical Wall

Support installation through a combustible wall.

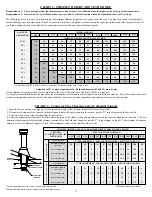

Distance

from Wall to

Chimney

6” ID

Chimney

7” ID

Chimney

8” ID

Chimney

H(feet)

Max. Height

H (feet)

Max. Height

H (feet)

Max. Height

D (inches)

Wall/Chimney

Table 2 - Wall Support

Chimney Height Chart

D

- Distance from wall to the chimney

H - Height of chimney in feet

See Figure 8 also.

1. Determine the centre line of the horizontal connection (Chimney

Length through the wall) and frame an opening to the dimensions

specified for the Wall Thimble in a combustible wall (see Section A

in Table 3 and Figure 13-A).

- Use a stud finder to roughly locate the walls studs. Mark the

outline of the hole and drill a pilot hole in its center.

3. After framing in your opening to the dimensions specified to the

Framing Tables 1 or 3, install the outer half (with the unfinished

square plate) of the Wall Thimble into the outside wall opening.

Secure in place with appropriate fasteners through the pre-punched

holes.

2. For a non-combustible wall (concrete block or poured

foundation), cut a hole (3/16”) greater in diameter than the outside

diameter of the chimney as per Table 3.

NOTE:

When cutting the inside "finished" surface of your wall cut

a

"round hole"

to the framing dimension in Table 3.

- Break out part of the wall covering within the outline to confirm

that the hole will be centered between studs and that no electrical

wires could be cut by the saw.

Wall Thimble

Black

Finishing

Round Plate

Interior Inner

Half of Wall

Thimble

Exterior Outer

Half of Wall

Thimble

Figure 12

Telescoping adjustment

from 4-1/2” to 8-3/4”

NOTE:

To reduce cold air infiltration into the dwelling you

can install the optional Universal Shielding Insulation (JUSI)

into the Wall Thimble. See separate installation instructions

packaged with the JUSI.

4. Install the inner half (with round plate) of the Wall Thimble into

the inside wall opening, ensuring that the shield slides over the shield

of the outer half. Once in place and flush against the wall, install the

black finishing trim plate onto the wall surface and fasten in place

with appropriate fasteners through the 4 pre-punched holes.

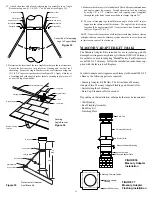

Two options are described below for the installation of the Wall

Support and the Insulated Tee assembly. Follow Method A if

inserting an assembled Insulated Chimney Length and Insulated Tee

into the Wall Thimble prior to the Wall Support. Follow Method B

if securing of the Wall Support to the wall prior to the Insulated Tee

and the Insulated Chimney Length.

METHOD A

6. Install an appropriate Insulated Chimney Length such as a one

foot section (or longer if required-not to exceed 24 inches) to the

horizontal branch of the Insulated Tee. Lock securely into the Tee

branch by twisting clockwise. A Locking Band must then be

installed to secure the connection. Make sure the nut and bolt are

facing down to prevent any water from collecting in the Locking

Band. The Tee branch extension must protrude a minimum of 3"

into the room.

5. Assemble the 2 side Brackets (point of triangle facing down) to

the Support Plate (flange up and threaded stud towards the wall) by

inserting the threaded studs into the oblong slots (see Figures 14 &

15). Install the supplied nuts on the threaded studs until snug, do not

tighten at this time as adjustments may be required. Set aside and

prepare the support bracing to secure the side brackets as per the

Framing Dimensions in Section B of Table 3 and Figure 13 (B).

7. From outside the building, slide the assembly (Chimney Length

installed on the Tee Branch) through the Wall Thimble ensuring the

male coupling on the Tee is facing upward. The Wall Thimble will

provide support until you are ready to install the Wall Support

Assembly.

8. Place the assembled Wall Support against the wall (Support Plate

Flange up) directly below the Insulated Tee. Slide the Wall Support

up to the bottom of the Insulated Tee ensuring that the flange on the

top of the Support Plate is inserted into the female coupler.

Table 3 -

Framing Dimensions Wall

Thimble & Support Brackets

Wall Thimble

Minimum Framed Opening

for Combustible Wall

Minimum Round Hole

Diam. For Non-Combustible Wall

Support Brackets

Minimum Framed Opening

For Bracing

Chimney Size (ID)

Figure 13