7

MAINTAIN PROPER SLOPE

• Install with a continuous 1/4” per foot (minimum) slope, as is required

by the National Fuel Gas Code for all gas-fired appliances.

• Vent systems for condensing appliances must have a continuous 1/4”

per foot (minimum) slope toward the appliance or a condensate drain.

Always check the appliance manufacturer’s instructions for proper drain

requirements.

• CAX1-(BC) offers a range of tees and elbows that are built incorporating

a 2 degree slope, we recommend that you use these to generate your

slope.

• Some appliances require the venting system to be sloped toward the

horizontal termination.

• Remember, if you raise the appliance or lower the ceiling you must adjust

the slope of the vent to maintain the 1/4” per foot minimum. See Figure

5 & 26.

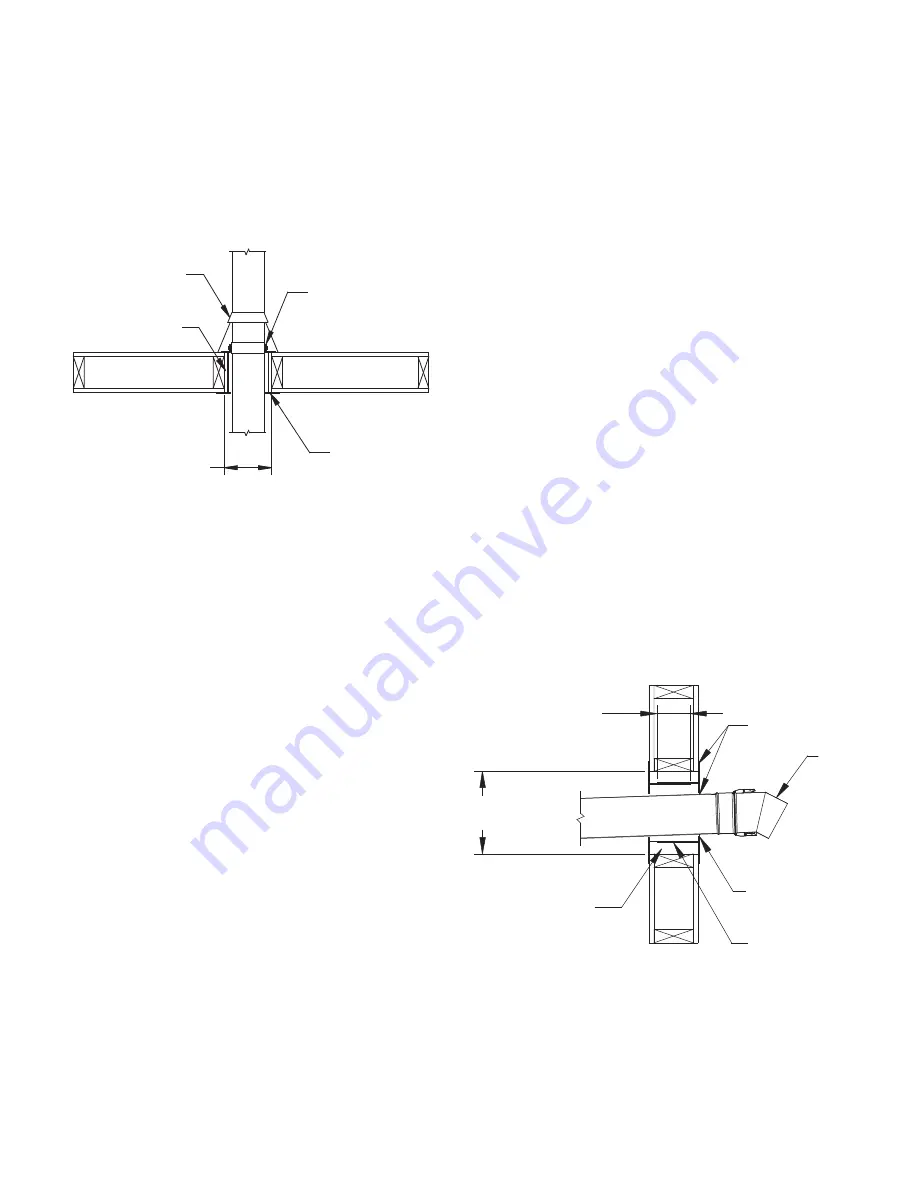

ROOF / FLOOR PENETRATION

1. A roof thimble (RT) or roof thimble insulated (RTI) for cold climate must

be installed every time the vent system passes through a floor or roof.

2. Prepare the roof / floor by cutting a square opening. See Table 5.

3. Install the roof thimble. You may cut the radiation sleeve if it is too long.

See Figure 3.

4. For roof installation, install a flashing.

Support or Guide

Roof thimble

Opening dimension See Table 5 for

all Models

Air gap

or insulated

Flashing

Figure 3 - Roof penetration

Figure 4 - Wall Penetration

Wall Thimble

(WT/WTI)

Air gap or insulated

Two half plate

Termination

Add sealant

Opening dimension

Table 5 for opening

for all Models

2” Minimum overlap

WALL PENETRATION

1. Prior to installation, determine proper location of wall thimble (WT) or

wall thimble insulated (WTI) so that a minimum slope of 1/4” (6mm)

per foot is maintained in the horizontal section of vent to ensure proper

flow of condensation.

2. Prepare the wall by cutting a square opening. See Table 5 for opening

for all Models.

3. Install the wall thimble by inserting the larger of the two parts on the

appliance (interior side). See Figure 4.

4. Next, apply a bead of sealant around the edges of the exterior (smaller

of the two parts) wall thimble component. Then install this part of the

wall thimble by inserting the smaller collar into the other component

from the previous step.

NOTE:

The two horizontal cylinders of the thimble must engage a

minimum of two inches.

5. Fasten both sides of the wall thimble using screws or nails.

6. Once the thimble is installed, vent pipe can be inserted into the thimble.

7. Close the gap between the thimble and the vent by installing the two

half plate and fasten it using screws or nails.

8. Install horizontal termination to complete the assembly.

9. Once assembly is completed, apply a bead of high-temp sealant around

the pipe and the exterior two half plates of the thimble to protect against

weather.

10. The air gap is filled with insulation when using the insulated wall thimble

(WTI).