5. OpeRATION

Original Language Version

4.

AIR sUppLy

4.1.

Ensure that the jack pneumatic switch is in the "off" position before connecting to the air supply.

4.2.

Use an air pressure of between 116psi and 174psi and an air flow of 10.5cfm to get the best performance from this jack.

4.3.

WARNING!

Ensure the air supply does not exceed the stated maximum pressure while operating the jack.

Too high an air pressure and unclean air will shorten the products life due to excessive wear, and may be dangerous causing possible

damage and personal injury.

4.4.

Drain the air tank daily. Water in the air line will damage the jack.

4.5.

Clean the air inlet filter screen weekly.

4.6.

Keep the air hose between the compressor and the air jack as short as possible, and install an air filter and oiler (fig.1).

4.6.

Line pressure should be increased to compensate for unusually long air hoses (over 8 metres). The minimum hose diameter should be

3/8" I.D. and fittings must have the same inside dimensions.

4.8.

Keep hose away from heat, oil and sharp edges. Check hoses for wear, and make certain that all connections are secure.

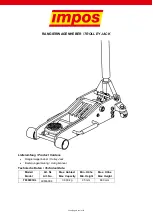

fig.1

5.1.

The jack can be carried by lifting with the carrying handle, which is at the point of balance.

WARNING:

The jack is heavy! (24kg)

5.2.

To make the jack manoeuvrable

,

the extension handle may be fitted.

5.2.1. Depress the handle lock pedal and swing the handle up to the required position (fig.3)

5.2.2. Remove the extension fixing screw from the handle (fig.4).

5.2.3. Place the extension handle so the notch in the cup fits around the control lever (fig.4)

5

.

2.4. Secure the extension by inserting the fixing screw through the extension into the handle

(fig.4).

5.2. preparation

5.2.1. Check that the air supply meets the requirements set out in section 4.

5.2.2. Connect the air supply to the connector (fig.4).

5.3.

purging the system

Before using the jack, purge the hydraulic circuit in order to eliminate any air that may

have entered the system during transit.

5.3.1. Push the control lever (fig.5) to the ‘down’ (fig.5.A) position and hold it for several

seconds. Release the lever to the centre ‘hold’ position.

5.3..2. Now push the lever to the ‘up’ position (fig.5.B) and hold it there until the jack is fully

extended. Push the lever to the ‘down’ (fig.5.A) position and observe the jack as it

retracts. The lowering movement should be smooth and even.

5.3.3. Repeat the raising and lowering cycle until the movement is smooth. Once achieved this

indicates that all air has been expelled.

5.4.

Using the Jack

WARNING!

Ensure that you have read and understood the safety instructions in

section 1 before commencing work.

5.4.1. Position the jack under the vehicle manufacturer’s recommended jacking point

(see vehicle handbook)

.

Note: Use the extension pins to increase the lift height of the jack.

5.4.2. Whilst holding the main jack handle, lifting is achieved by pushing the control

lever

to

the 'up' position (fig.5.B).

5.4.3. When the vehicle has reached the desired height release the control lever which will

return to the middle hold position. This will automatically stop any further air flow and hold

the

jack.

5.4.4. Place axle stands correctly in position and ensure section 1 safety instructions are

applied strictly before performing any task.

5.5.

Lowering the Jack

5.5.1 Ensure there are no persons or obstruction beneath the vehicle before lowering.

5.5.2. Raise the the load clear of any axle stands and remove them.

5.5.3. Whilst holding the main jack handle, lowering is achieved by pushing the control lever

to the 'down' position (fig.5.A), and the jack will lower in a controlled manner.

5.5.4. Once lowered completely, releasing the control lever will return to the middle hold position.

Remove the jack from under the vehicle. If no longer needed, turn the air pressure supply off and disconnect from the air line and

store the jack and air line in a safe, dry location.

© Jack Sealey Limited

fig.3

fig.4

fig.5

Only fully qualified personnel should attempt maintenance or repair.

WARNING!

Disconnect jack from air supply before changing parts, servicing or performing any

maintenance.

6.1. When the jack is not in use, the piston rod must be in the lowest position to minimise corrosion.

6.2. Keep the jack clean and lubricate all moving parts on a regular basis.

6.3. To check oil level, lower jack fully. Remove the bolt (fig.6). The correct oil level should be up to

the entrance of the oil filler opening.

If oil level is low, fill as required.

NOTe:

Use a good quality Jack oil, such as SEALEY

HYDRAULIC JACK OIL.

6. MAINTeNANCe

WARNING!

DO NOT

use brake fluid, or any fluid other than hydraulic jack fluid as this may cause

serious damage to the jack and will invalidate the warranty.

WARNING!

wear safety goggles.

fig.6

YAJ15-30F_V2 Issue: 1 - 11/09/18