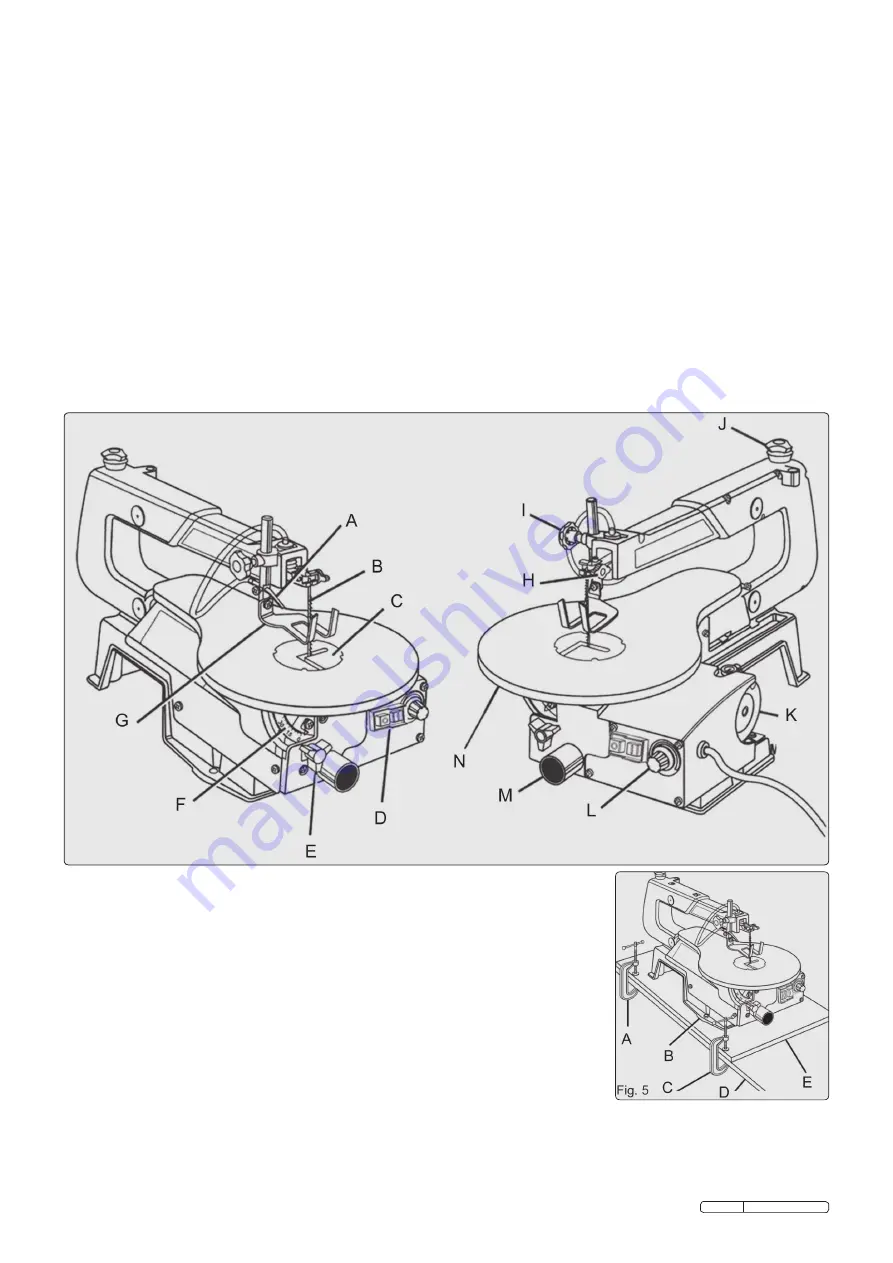

4.2. MAIN PARTS DESCRIPTION

Before attempting to use your saw, familiarise yourself with all the operating features and safety requirements of your scroll saw. see figure 4.

Sawdust Blower:

Keeps the line of cut on the workpiece clean for more accurate scroll cuts. for best results, always direct the airflow at the

blade and the workpiece.

Saw Table with Throat Plate:

Your scroll saw has a saw table with tilt control for maximum accuracy. the red throat plate, inserted in the saw

table, allows for blade clearance.

Switch:

Your scroll saw has an easy access power switch. o = off I=on

Table Lock Knob:

Allows you to tilt the table and lock it at the desired angle (up to 45°).

Bevel Scale:

the bevel scale shows you the degree at which the saw table is tilted.

Drop Foot:

this foot should always be lowered until it just rests on top of the workpiece to prevent it from lifting, yet not so much as to make

the workpiece drag.

Blade Clamp Screws:

Blade clamp screws are used to tighten and loosen the blade clamps when changing saw blades.

Drop Foot Lock Knob:

this knob allows you to raise or to lower the drop foot and lock it in the required position.

Blade Tension Knob:

to loosen or tighten blade tension, turn the blade tension knob.

Speed Selector:

turn the knob to adjust the speed from 400 to 1,600 strokes per minute.

Sawdust Outlet:

this feature will allow you to attach any 1¼ in. (32 mm) vacuum hose for easy sawdust collection.

Fig. 4

A. sAWdust BloWer

H. BlAde clAMP screWs

B. sAW BlAde

I. droP foot locK KnoB

c. tHroAt PlAte

J. BlAde tensIon KnoB

d. sWItcH

K. Motor

e. tABle locK KnoB

l. sPeed selector

f. BeVel scAle

M. sAWdust outlet

G. droP foot

n. sAW tABle

4.3

BOLTING THE SCROLL SAW ONTO A WORKBENCH. See Figure 5.

WARNING!

to avoid serious personal injury from unexpected tool movement, securely

mount the scroll saw onto a workbench. If the scroll saw is to be used in a specific location,

we recommend that you secure it to a workbench in a permanent way. for this purpose,

holes should be drilled through the supporting surface of the workbench.

4.3.1 each hole in the base of the saw should be bolted securely using machine bolts, washers,

and nuts (not included).

4.3.2 Bolts should be long enough to accommodate the saw base, washers, nuts, and the

thickness of the workbench.

4.3.3 Place the scroll saw on the workbench. using the saw base as a pattern, locate and mark

the holes where the scroll saw is to be mounted.

4.3.4 drill four holes through the workbench.

4.3.5 Place the scroll saw on the workbench aligning the holes in the saw base with the holes

drilled in the workbench.

4.3.6 Insert all four bolts (not included) and tighten securely with washers and nuts (not included).

Note: All bolts should be inserted from the top. Fit the washers and nuts from the underside of the

bench.

The supporting surface where the scroll saw is mounted should be examined carefully after

mounting to insure that no movement will occur while cutting.

fig. 5

A. c-clAMP

d. WorKBencH

B. sAW BAse

e. MountInG BoArd

c. c-clAMP

fig. 4

Original Language Version

sM1302 Issue: 2 - 12/01/10