fig.6

5.6.

OPERATIONS TO BE CARRIED OUT EVERY 500 HOURS:

a) Replace air filter (See fig.4).

b) Check all tube fittings and electrical connections.

5.7.

Recommended oils;

Recommended oil for compressors, suitable for room

temperatures ranging from +5°C to +25°C.

SEALEY CPO or equivalent SAE 40 compressor oil. Room

temperature below +5°C: SAE 20 compressor oil.

Approximate oil capacity: 0.16 litres.

5.8

IMPORTANT WARNING

- Air contaminants taken into the

compressor will affect optimum performance. Example: Body

filler dust or paint overspray will clog the pump intake filter

and may cause internal damage to pump/motor components.

Please note that any parts damaged by any type of

contamination will not be covered by warranty.

NOTE:

It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT:

No liability is accepted for incorrect use of this product.

WARRANTY:

Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION:

For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park

,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

6. TROUBLESHOOTING

FAULT

CAUSE

REMEDY

1A) Pressure drop in the tank

Air leaks at connections

Run compressor to max. pressure, switch off.

Brush soap solution over connections and look for

bubbles. Tighten connections showing leaks.

If problem persists contact Authorised Service Agent

1B) Pressure drop in the tank

Air leaks from safety valve

Operate the safety valve manually by pulling on the

ring. If valve continues to leak when in the closed

position it should be replaced

1C) Pressure drop in the tank

Air leaks from cylinder head gasket

Check tightness of head bolts. If leak continues

contact authorised Service Agent

2) Pressure switch valve leaks when

compressor is idle

Non-return valve seal defective

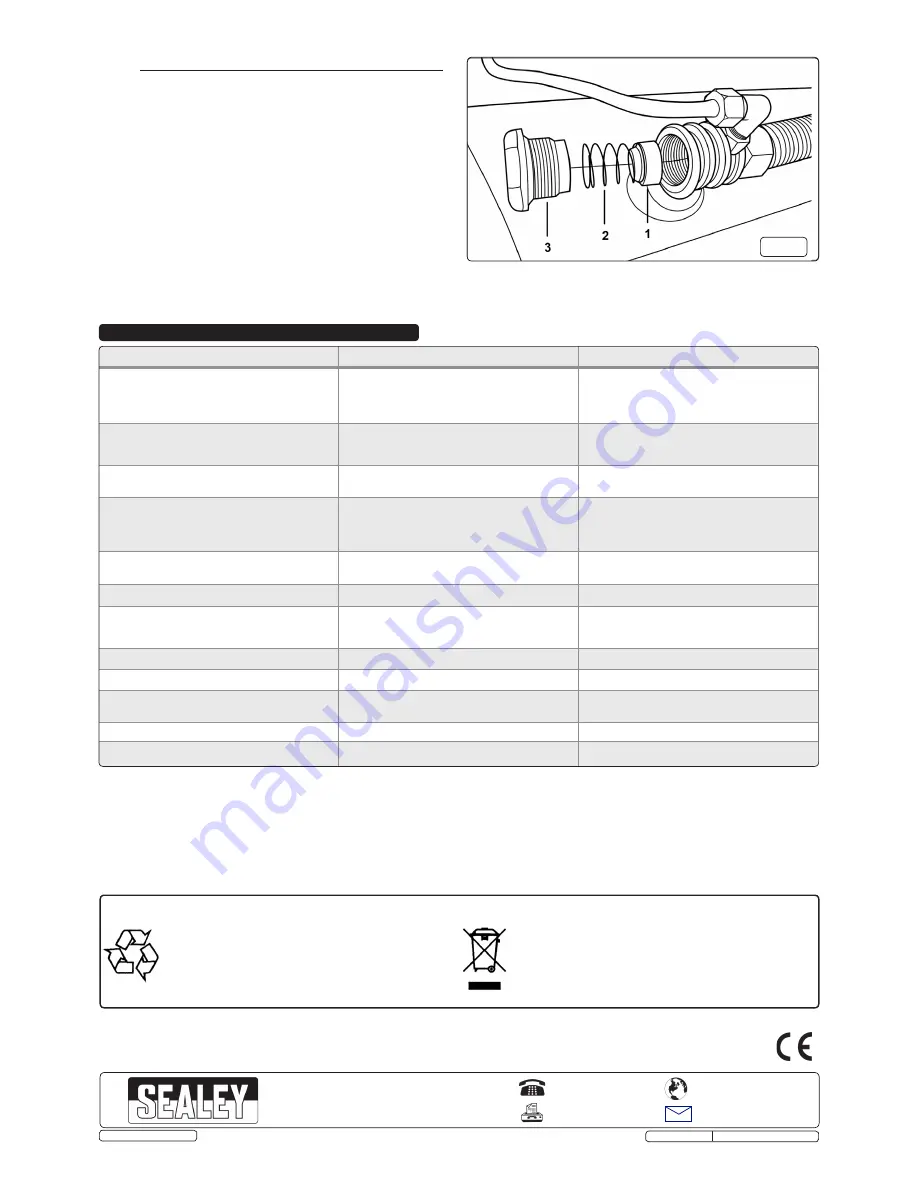

Empty the air tank. Referring to fig.7, remove the

non-return valve cap (3), spring (2) and seal (1).

Clean the seal and its seat, or if necessary replace

the seal

3) Air leaks from tank body or tank welds

Internal corrosion caused by infrequent tank

draining or non permitted modifications to tank

Tank could rupture or explode. Cannot be repaired

DISCONTINUE USE IMMEDIATELY

4A) Motor stops and will not restart

Thermal cut out has operated

Allow unit to cool for 30 minutes before restarting

4B) Motor stops and will not restart

Supply fuse has tripped

Press trip reset button (fig.6) and restart unit. If

repeated tripping occurs replace the check valve or

contact authorised Service Agent

5) Compressor stops and does not restart

Motor failure

Contact Authorised Service Agent

6A) Compressor does not stop at max. pressure

Pressure switch fault

Contact Authorised Service Agent

6B) Compressor does not stop at max. pressure

Filter clogged

Head gasket or valve fault

Replace filter element.

Contact Authorised Service Agent

7) Compressor noisy with metallic knock

Bearing or piston damage

Contact Authorised Service Agent

8) Excessive moisture in discharged air

High humidity environment

Drain tank after each use

fig.7

Original Language Version

© Jack Sealey Limited

5.9

Inspection of pressure tank both inside and out.

Under the PRESSURE SYSTEMS SAFETY REGULATIONS 2000 it is the responsibility of the owner of the compressor to initiate a

system of inspection that both defines the frequency of the inspection and appoints a person who has specific responsibility for

carrying out the inspection.

Environmental Protection.

Recycle unwanted materials instead of disposing of them as

waste. All tools, accessories and packaging should be sorted,

taken to a recycle centre and disposed of in a manner which

is compatible with the environment.

When the product becomes completely unserviceable and

requires disposal, drain off the oil into an approved container and

dispose of the product and the oil according to local regulations.

WEEE Regulations.

Dispose of this product at the end of its working life in compliance

with the EU Directive on Waste Electrical and Electronic Equipment.

When the product is no longer required, it must be disposed of in an

environmentally protective way. Contact your local solid waste

authority for recycling information.

SAC10030VE Issue No: 2(I) - 17/04/14