PROBLEM

POSSIBLE CAUSE

SOLUTION

Excessive noise

1. Incorrect belt tension

1. Adjust tension

2. Spindle is dry

2. Disassemble spindle/quill and lubricate

3. Pulley is loose

3. Tighten pulley

4. Bearing damaged

4. Replace the bearing

Excessive drill wobble

1. Chuck is loose

1. Tighten the chuck by pressing it against the table (see 5.2.12)

2. Bearing or spindle shaft is worn

2. Replace worn part

3. Chuck is worn

3. Replace the chuck

Drill binds in the

1. Feed pressure is wrong

1. Apply less pressure

workpiece

2. Belt is loose

2. Adjust tension

3. Drill bit is loose

3. Tighten the chuck jaws with the key

4. Speed is too fast

4. Change the speed

Drill burns or smokes

1. Speed is too fast

1. Change the speed

2. Chips are not discharging

2. Clean the drill bit

3. Drill bit is dull

3. Use a new bit

4. Lubrication needed

4. Lubricate while drilling

5. Feed pressure is wrong

5. Apply less pressure

Table is difficult to raise

1. Lubrication is needed

1. Lubricate with light oil

2. Rack is bent

2. Straighten the rack

9. TROUBLESHOOTING

8.1. Clean the tool after each use. A coat of automobile-type wax applied to the table and

column will help to keep the surfaces clean.

8.2. Blow out any dust that may have accumulated in the motor.

8.3. Periodically lubricate the table elevation rack/gear/worm mechanism and the spindle sleeve exterior.

8. MAINTENANCE

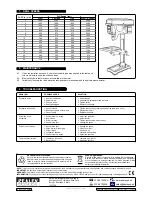

7. DRILL SPEEDS

Drill Speed (rpm)

Drill Dia. (mm)

Steel

Cast Iron

Iron

Alum. & Copper

3

1820

2580

2580

2580

4

1350

1820

1820

2580

5

1290

1350

1350

2580

6

970

1290

1290

2580

7

830

970

970

2580

8

830

970

970

2580

9

500

970

830

1820

10

500

830

830

1820

11

500

830

830

1820

12

420

830

500

1820

13

420

500

500

1350

14

420

500

500

1350

16

320

500

500

1290

18

320

420

420

1290

20

280

320

320

970

22

210

320

280

970

25

120

280

210

830

NOTE:

It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT:

No liability is accepted for incorrect use of this product.

WARRANTY:

Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION:

For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park

,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

Original Language Version

PDM100B, PDM125B, PDM155B Issue: 4 (SP) - 10/12/13

© Jack Sealey Limited

Environmental Protection.

Recycle unwanted materials instead of disposing of them as

waste. All tools, accessories and packaging should be sorted,

taken to a recycle centre and disposed of in a manner which

is compatible with the environment.

WEEE Regulations.

Dispose of this product at the end of its working life in compliance

with the EU Directive on Waste Electrical and Electronic Equipment.

When the product is no longer required, it must be disposed of in an

environmentally protective way. Contact your local solid waste

authority for recycling information.