2. INTRODUCTION

High powered, lightweight industrial unit with blower facility. Constructed from stainless steel, the drum unit is mounted on two

castor and two fixed wheels. Tool storage points on head and base. Supplied with 4.5m cable with 3-pin plug, deluxe tool kit,

including stainless steel telescopic rigid extension tube, cartridge filter and wet-use foam filter.

3. CONTENTS

3.1.

CARTON CONTENT

3.1.1.

Carefully unpack the carton.

3.1.2.

Locate the two side clasps (fig.1.6) which hold the top

section (fig.1.3) in place.

3.1.3.

Undo the clasps, remove the power head and take out

the items in the container.

3.1.4.

Check and identify each component as listed below.

If anything is missing or damaged please contact your supplier

immediately.

4. SPECIFICATION

MODEL NO: ...........................................................PC200SD.V3

A

irflow:

.........................................................................

120 m³/hr

Drum Size: ...........................................................................20 L

Filter Type: ................................................................... Cartridge

Maximum Vacuum Pressure: ........................................140 mbar

Motor Power: ...................................................................

1250 W

Supply: .............................................................................. 230 V

Vacuum Accessories Diameter: .....................................

Ø35 mm

Optional Accessories:

P

C200PB5

.................................

Optional Dust Bags (Pack of 5)

Replacement Parts:

PC200CFL .......................................................... Cartridge Filter

PC200FF10 .........................................Foam Filters (Pack of 10)

5. ASSEMBLY

5.1.

Ensure the mains plug is disconnected. (fig.2.1)

5.2.

Undo clasps. (fig.2.2)

5.3.

Lift off the power head assembly. (fig.2.3)

5.4.

Remove contents from inside the container. (fig.2.4)

5.5.

Turn the drum upside down and insert the castor assembly

mouldings into the slots in the base either side of the blue

drain cap. Ensure they are pushed all the way in and fix them

with the self tapping screws provided. (fig.2.5a)

DO NOT

overtighten.

5.6.

The wheel assembly mouldings are marked 1 and 2. Insert

the wheel assembly mouldings into the two remaining slots

in the base ensuring that the number on each moulding

matches the number to be found on the base. Ensure they

are pushed all the way in and fix them with the self tapping

screws provided (fig.2.5b)

DO NOT

overtighten.

5.7.

For dry vacuum cleaning use the locking cartridge filter

supplied and with the raised rim uppermost fit the cartridge

filter tube down over the filter basket and push fully home.

Place the locking disc onto the top of the filter and turn

the locking bar until the latch drops into the slot in the top

of the filter basket. Continue turning until the filter is fully

locked down. (fig.2.6)

5.8.

For wet vacuum cleaning fit the supplied foam filter. (fig.2.7)

NOTE:

DO NOT

operate the cleaner without a cartridge filter

fitted as this will damage the machine and invalidate your

warranty.

5.9.

Replace the power head assembly onto the drum ensuring

Original Language Version

© Jack Sealey Limited

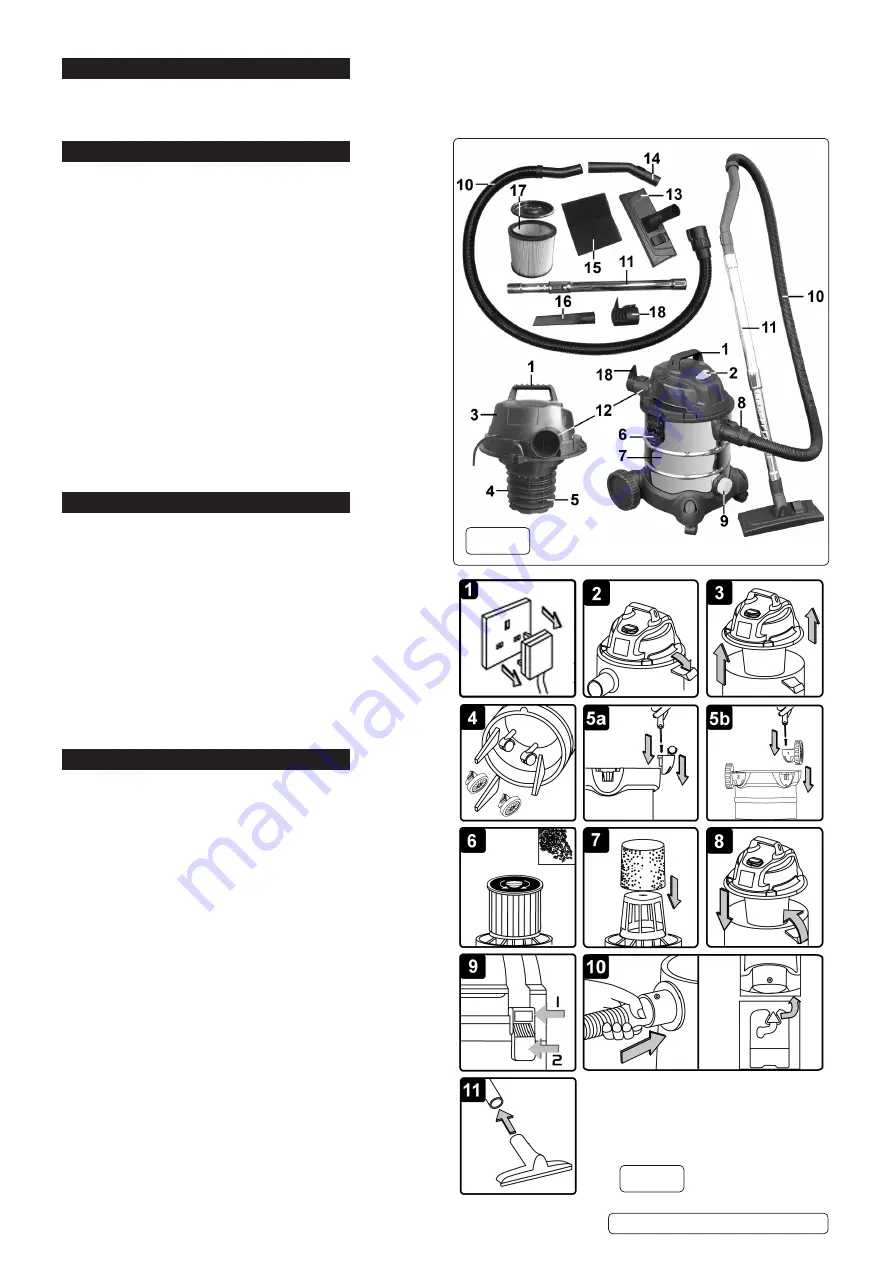

Item Description

1 Handle

2 ON/OFF switch

3 Top section

4 Filter basket

5 Safety float valve

6 Clasp

7 Stainless Steel drum

8 Vacuum hose connection

9 Drain Cap

10

Flexible vacuum hose

Item Description

11 Telescopic suction tube

12 Blow connection

13 Combination brush

14 Elbow tool

(Air regulator handle)

15 Foam filter

16 Crevice tool

17 Locking Cartridge filter

(fitted as standard)

18 Noise muffler

fig.2

fig.1

P

C200SD.V3 Issue 4 (4,F) 08/09/20