SPECIFICATION, Model No: ......................................................MIGHTYMIG170

Maximum Current: ......................................................................................... 170A

Wire Capacity steel: ..........................................................................................5kg

duty Cycle: .......................100% @ 55Amps, 60% @ 70Amps, 15% @ 140Amps

Cooling System: ..................................................................................... Forced Air

Gas Type: .................................................................CO², Argon & CO²/Argon mix

Torch: ................................................................ euro Non live - BINZel ® MB1

5

Power Input ............................................................................................. 230V 1ph

Absorbed power ........................................................................................... 5.4kW

Case size ...................................................................................................... large

Weight ..........................................................................................................41.5kg

SPECIFICATION, Model No: . . . . . . . . . . . . . . . . . . . . . . . . . . .MIGHTYMIG190

Maximum Current: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190A

Wire Capacity steel: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15kg

duty Cycle: . . . . . . . . . . .100% @ 70Amps, 60% @ 90Amps, 15% @ 180Amps

Cooling System: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Forced Air

Gas Type: .................................................................CO², Argon & CO²/Argon mix

Torch: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . euro Non live - BINZel ® MB15

Power Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230V 1ph

Absorbed power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.2kW

Case size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . large

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.5kg

SPECIFICATION, Model No: . . . . . . . . . . . . . . . . . . . . . . . . . . .MIGHTYMIG210

Maximum Current: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210A

Wire Capacity steel: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15kg

duty Cycle: . . . . . . . . . .100% @ 80Amps, 60% @ 105Amps, 15% @ 210Amps

Cooling System: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Forced Air

Gas Type: .................................................................CO², Argon & CO²/Argon mix

Torch: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . euro Non live - BINZel ® MB15

Power Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230V 1ph

Absorbed power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0kW

Case size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . large

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45.5kg

3. ASSEMBLY & PREPARATION

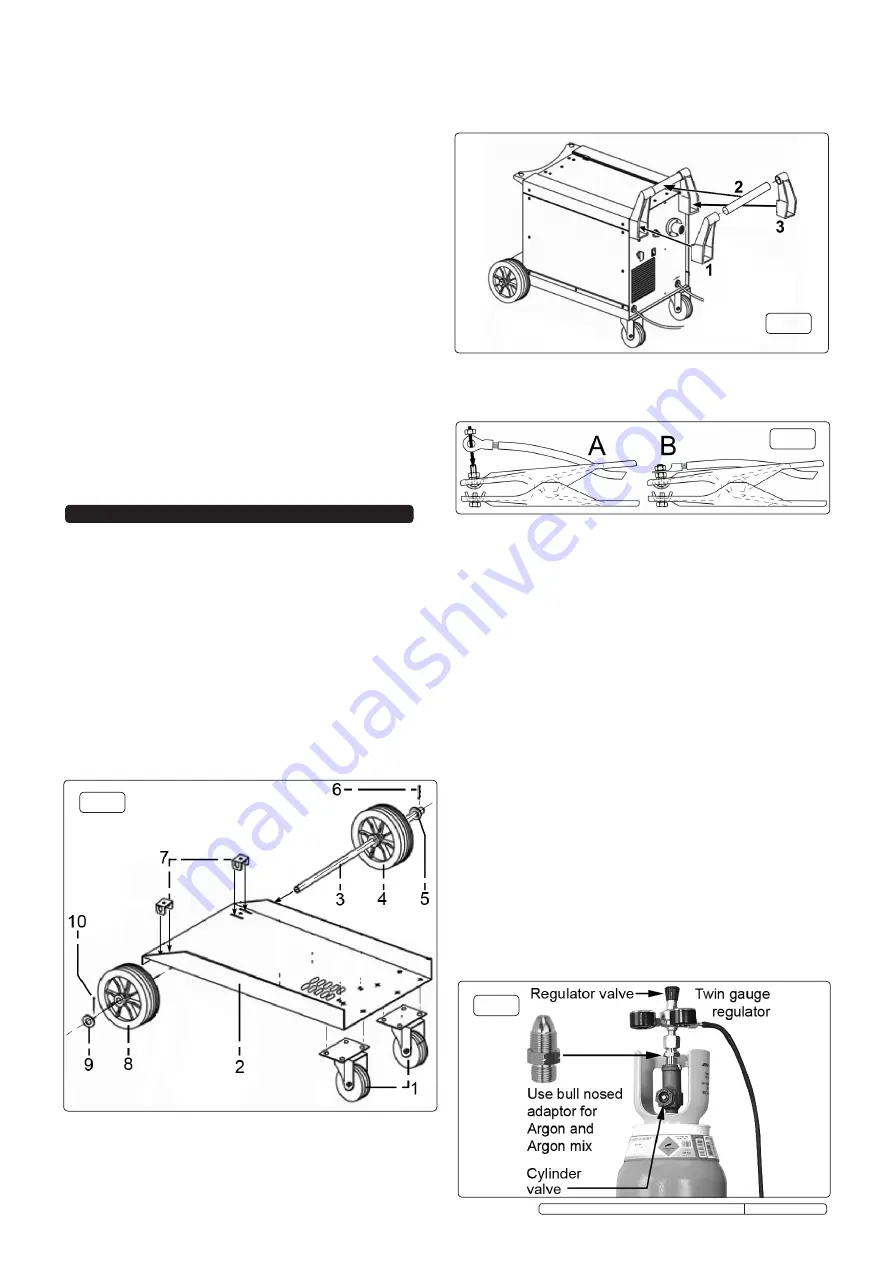

fig.1

3.1

ASSEMBLING THE WHEELS:

(Refer to fig.1) The wheels are more

easily assembled with the welder placed upside down on a smooth

non-abrasive surface. The welder should be turned over by two people

as it is very heavy.

3.1.1

Bolt the two castors (1) to the front end of the base (2) using the bolts

provided.

3.1.2

Take the solid axle (3) and slide a wheel (4) over one end followed by a

washer (5). Insert a split pin (6) through the hole in one end of the axle

as shown below and bend it over.

3.1.3

Take an axle retaining bracket (7) and insert it into the slots in the base

(2). Hold the bracket in place and slide the axle assembly through both

parts of the bracket. Insert the second axle retaining bracket (7) through

the base and continue to slide the axle across so that it passes through

the second bracket and holds the wheel (4) up against the side of the

base. Slide the second wheel (8) onto the free end of the axle followed by

a washer (9). Retain the entire axle assembly by passing a split pin (10)

through the free end of the axle and bend it over to retain the whole axle

assembly.

3.1.4

With the assistance of another person turn the welder the right way up

onto its wheels.

3.2

ASSEMBLING THE HANDLE:

(Refer to fig.2) On the front of the welder

there are two pairs of threaded inserts, one pair in the top left corner and

one pair in the top right hand corner..

3.2.1

Attach the left hand handle mounting (1) to the front of the welder using

two of the 25mm round headed bolts provided. do not fully tighten yet.

3.2.2

Slide the handle tube (2) into the socket in the mounting and push fully

home.

3.2.3

Slide the socket on the right hand handle mounting (3) over the free end

of the handle tube and rotate the mounting downwards until it is resting

on the front of the welder. Using two of the 25mm round headed bolts

provided to fix the right hand mounting in place.

3.2.4

Now fully tighten all four fixings.

3.3

ASSEMBLING THE EARTH CLAMP:

(Refer to fig.3) Feed the eyelet on the

end of the earth lead through the hole in the clamp arm as shown in fig.3A.

3.3.1

drop the eyelet over the terminal and firmly fix with the bolt provided as

shown in fig.3B.

fig.3

3.4

INSTALLING THE GAS CYLINDER.

The welder is designed to

accommodate small or medium sized gas cylinders up to a maximum

height of 1000mm. Contact your local Gas dealer for supply.

3.4.1

Place the gas cylinder onto the rear platform of the welder. drop one

end of the fixing chain into one side of the retaining bracket. draw

the chain around the cylinder and place it into the slot on the other

side of the bracket leaving as little slack in the chain as possible.

3.5

ATTACHING THE REGULATOR.

Whichever gas you are using it is

advisable to 'crack' the cylinder valve before attaching the regulator.

This means opening and closing the valve very quickly in order to

blow away any dust and dirt that may have accumulated in the gas

outlet. Stand to one side whilst doing this.

3.5.1

CO² GAS.

ensure that the threads on the gas bottle are undamaged

and free of oil and grease before attaching the regulator. (Oil or

grease in the presence of high pressure gases can be explosive.)

ensure that the regulator has an undamaged gasket fitted. The

regulator will screw directly to the threads on the gas bottle. Tighten

with a spanner.

3.5.2

ARGON GAS OR ARGON MIxTURES.

Cylinders containing Argon

gas and Argon mixtures have a female thread and will require the use

of a Bull Nose Adaptor to attach the regulator to the cylinder as

indicated in fig.4. ensure that the threads on the gas bottle are

undamaged and free of oil and grease before attaching the regulator.

(Oil or grease in the presence of high pressure gases is explosive.)

Fit the Bull Nose Adaptor to the cylinder first and tighten with a

spanner. ensure that the regulator has an undamaged gasket before

fitting onto the Bull Nose Adaptor. Tighten with a spanner.

3.5.3

Slide a jubilee clip over each end of the gas hose supplied. Push

one end of the hose onto the regulator outlet and the other end over

the gas inlet spigot on the back of the welder. Tighten the clips to

ensure a good seal.

3.5.4

Close the regulator valve by turning it anticlockwise before opening

the cylinder valve. Stand to one side when opening the cylinder valve.

3.5.5

Set the regulator flow rate to 5-8 litres/min depending on the

material to be welded, and whether there are draughts which are

strong enough to disturb the gas flow.

fig.4

fig.2

Original Language Version

MIGHTYMIG170, MIGHTYMIG190, MIGHTMIG210 Issue: 2 - 26/02/10