Original Language Version

© Jack Sealey Limited

4.4.

Drain the compressor air tank daily. Water in the air line will damage the tool.

4.5.

Clean compressor air inlet filter weekly.

4.6.

Line pressure should be increased to compensate for unusually long air hoses (over 8 metres). The minimum hose diameter should be

1/4” I.D. and fittings must have the same inside dimensions.

4.7.

Keep hose away from heat, oil and sharp edges. Check hose for wear, and make certain that all connections are secure.

4.8.

COUPLINGS

4.8.1.

Vibration may cause failure if a quick change coupling is connected directly to the tool.

4.8.2.

To overcome this, connect a leader hose to the tool. A quick change coupling may then be used to connect the leader hose to the air

line recoil hose. See figs.1 & 2.

5. OPERATION

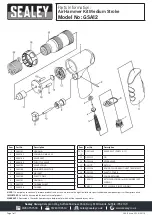

Note: Numbers in brackets refer to item numbers in the parts list.

5.1.

The air hammer is designed primarily for use on vehicle bodywork. We do not recommend any other use. Ensure you read, understand

and follow the safety instructions in Section 1.

5.2.

Attach the retaining spring (20) by screwing it onto the cylinder (18).

5.3.

Insert the chisel using the hooked end of the spring to hold the chisel in place.

5.4.

Attached the tool to the air supply (see Section 4).

5.5.

To operate the hammer, squeeze the trigger (11).

6. MAINTENENCE

WARNING!

Disconnect the hammer from the air supply before changing chisels, servicing or performing any maintenance.

6.1.

Keep the hammer oiled for optimum performance.

Lubricate with a good grade of air tool oil such as Sealey ATO/500 or ATO/1000.

If there is no oiler in the air system then a teaspoon of oil can be poured into the air inlet of the hammer, or into the hose at the nearest

connection to the air supply. Then run the hammer for a short time.

Note:

The following external factors may cause loss of power and effect hammer performance:

6.2.

The air supply:

reduced compressor output, excessive drain on the air line, moisture or restrictions in air pipes or the use of hose

connectors having too small a bore. Correct as necessary.

6.3.

The hammer:

grit or gum deposits in the tool. Correct by cleaning the air strainer and flushing out the tool with gum solvent oil or an

equal mixture of SAE No.10 oil and kerosene. If, despite taking action as above, the tool function is still impaired, contact your local

Sealey service agent.

.

fig.1

fig.2

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500

01284 703534

www.sealey.co.uk

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

Note

: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior

notice.

Important

: No Liability is accepted for incorrect use of this product.

Warranty

: Guarantee is 12 months from purchase date, proof of which is required for any claim.

GSA12 | Issue:5 (H,F) 02/01/20