4. PARTS LIST

1

FJ48/01

LARGE RUNNER

2

FJ48/02

STEEL BAR

3

FJ48/03

CONNECTING ROD

4

FJ48/04

ROCKER

5

FJ48/05

WASHER

6

FJ48/06

NUT

7

FJ48/07

PIN

8

FJ48/08

SCREW

9

FJ48/09

WASHER

10

FJ48/10

REVERSING LATCH

11

FJ48/11

REVERSING SWITCH

12

FJ48/12

SCREW BOLT

13

FJ48/13

NUT

14

FJ48/14

WASHER

15

FJ48/15

BASE

16

FJ48/16

SCREW BOLT

17

FJ48/17

SCREW BOLT

18

FJ48/18

SPRING

19

FJ48/19

PIN

20

FJ48/20

REVERSE ROD

21

FJ48/21

SPRING

22

FJ48/22

SPRING

23

FJ48/23

WASHER

24

FJ48/24

NUT

25

FJ48/25

SMALL RUNNER

26

FJ48/26

SPRING LOCK WASHER

Declaration of Conformity

We, the sole importer into the UK, declare that the product listed below

is

in conformity with the following EEC standards and directives

Farm Jack Model FJ48

98/37/EC Machinery Directive

(S.I. 1992/3073 & Amendments).

15th June 2000

Signed by Mark Sweetman

The construction file for th

is

product

is

held by the Manufacturer and may be inspected, by a national authority, upon

request to Jack Sealey Ltd.

For Jack Sealey Ltd.

Sole importer into the UK

of Sealey

Quality Machinery

Sole UK Distributor

Sealey Group,

Bury St. Edmunds, Suffolk.

01284 757500

E-mail:

01284 703534

NOTE:

It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT:

No liability is accepted for incorrect use of product.

WARRANTY:

Guarantee is 12 months from purchase date, proof of which will be required

for any claim.

INFORMATION:

For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

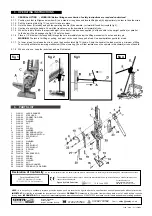

3.1.

GENERAL LIFTING

p

WARNING! Before lifting ensure Section 1 safety instructions are read and understood.

3.1.1. Position jack foot (all figures below item B) on a stable, strong base and locate lifting beak (A) appropriately in order to take the strain.

3.1.2. Pull the direction latch (fig 1.C) up until it clicks into place.

3.1.3. Hold the beam (D) steady and pull the operating handle (E) downward, (or forward if used horizontally fig 3).

3.1.4. Continue to pump the handle. You will feel resistance on the downward (or forward) stroke.

3.1.5. When the load is lifted to the required height, (or correct strain has been applied), set the handle in the upright position (or parallel

to the beam (D) and engage clip (fig 1.G) onto the beam.

3.1.6. Place a 1/2 steel bolt (not supplied) through the hole immediately below the lifting mechanism to act as a safety pin.

p

WARNING!

The jack is for lifting or pulling, and must not be used to support a load. Use appropriate supports for a load.

3.1.7. To lower a load, (or release the strain), push the direction latch (fig1.C) down. Pump the handle (the load must be a minimum of 50kg

To correctly activate the lowering mechanism). When lowering, you will feel resistance on the upward (or backward) stroke of handle.

3.1.8. When not in use, keep the jack clean and well lubricated.

3. OPERATING INSTRUCTIONS

fig 1

fig 2

fig 3

fig 4

FJ48 - 0016 - (1) - 150600