60

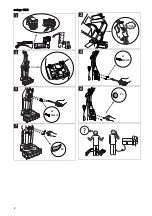

Beginning work with the machine

Cleaning start

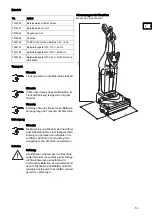

Setting the brush pressure

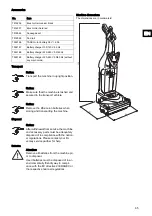

Cleaning method

Direct working method:

Scrubbing and suction in one work step.

Indirect working method:

Applying the cleaning solution, scrubbing and suction in sev

-

eral work steps.

Replenishing cleaning solution

Attention:

Always wear slip-resistant shoes and ap

-

propriate working clothes when working

with this machine!

Attention:

Start familiarization with the machine by

making your first driving attempts in a free

area.

• Switch on the machine (main switch).

• Hold the machine firmly by the han

-

dle and bring it into the working posi

-

tion (2) by pressing the red foot pedal

(1).

The electrical brushes switch on.

• Press the suction switch (1) to switch

on the suction unit. (no lamp).

• Press the cleaning solution switch (2)

to open the solenoid valve.

Switch lights up

Attention:

If the red brush pressure control lamp

lights up, correct the brush height as de

-

scribed below.

• Adjust the brush height (brush pres

-

sure) by turning the regulator until the

green display lights up.

LED display

Status indicator

Display green

Brush height (brush pressure) correctly

set.

Display red

Correct the brush height (brush pres

-

sure). Turn the setting knob to the right for

more, and to the left for less brush pres

-

sure.

1

2

1

2

Notice:

More precise details regarding the direct

and indirect working method can be found

on the respective method sheet.

Please contact your TASKI customer con

-

sultant for further details.

Attention:

The flooring may be damaged when work

-

ing without cleaning solution.

• The machine must be switched off.

• Open the tank lid.

• Fill the fresh water tank with water, see page 59.

• Add the cleaning product using the dosing cup.

• Close the tank lid.