NOTES

The electrical installation and the operation logics must comply with current regulations. Keep the power cables (motors, power supply)

separated from the control cables (push-buttons, photo-eyes, radio, etc.). Separate conduits should be used to prevent noise issues.

Note:

Use “cable clips” and/or “duct/box pipes” fitting close to the control panel box so to protect the interconnection cables against pulling

efforts.

INTENDED USE

VERG system has been designed exclusively for the automation of barriers.

SPARE PARTS

The spare parts orders must be sent to:

SEA S.p.A. Zona Ind.le, 64020 S.ATTO Teramo Italy

SAFETY AND RESPECT FOR THE ENVIRONMENT

We recommend not to spoil the environment with product and circuit packing material.

STORAGE

STORAGE TEMPERATURE

T

min

-30°C

T

max

+60°C

Humidity

min

5% without condensation

Humidity

max

90% without condensation

The product must be handled using suitable means.

LONG-TERM STOP AND MAINTENANCE

The disassembly and/or stop and /or maintenance of the VERG automation system must be carried out by skilled and expert technicians.

GUARANTEE LIMITS

For the guarantee see the sales conditions on the official SEA price list.

NOTE: THE MANUFACTURER SHALL NOT SHOULDER ANY RESPONSIBILITIES IN CASE OF DAMAGE CAUSED BY

INAPPROPRIATE, WRONG OR CARELESS USE.

SEA reserves the right to make all the necessary changes and modifications of the products and / or manuals without giving prior

notice.

English

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

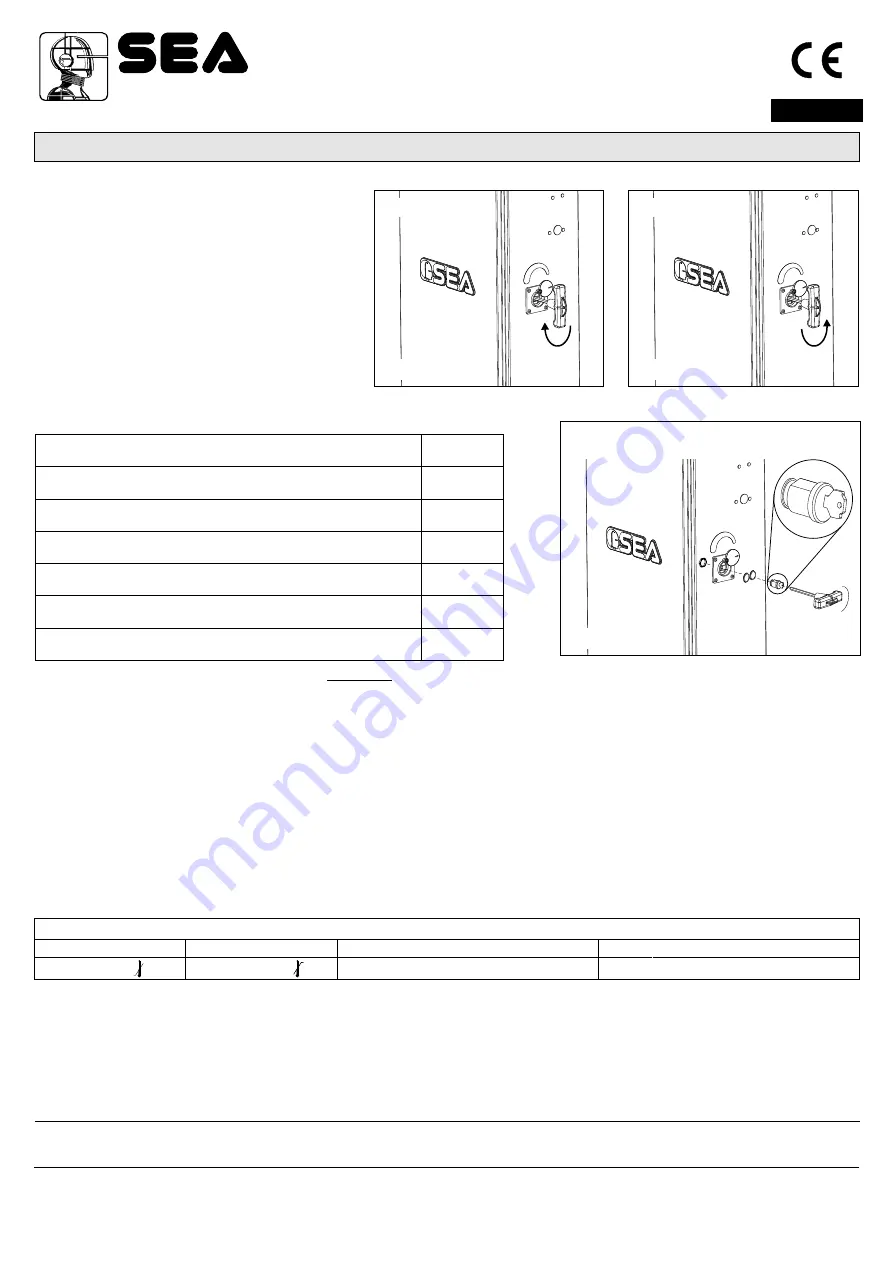

11) Release system

To release operate as follows

- Turn the protection cap of the release.

-

Insert the

and turn it about 180° into

clockwise direction until the beam is released (Fig.

12).

- Open manually the beam.

To re-lock operate as follows

- Turn the

into anti-clockwise direction

(Fig. 13).

- Extract the key.

- Re-close the protection cap.

T shaped key

T shaped key

PERIODICAL MAINTENANCE

All above mentioned operations must be executed exclusively by authorized installers.

Check the functionality of the release

Lubricate the bearing of the balance

Check the efficiency of the spring

Check the beam fixing screws and the balance and the casing

Check the integrity of the connexion cables

Check the efficiency of the batteries (where included)

Check and eventually adjust the value of intervention of the

anti-crash sensor.

Annually

Annually

Annually

Annually

Annually

Annually

Annually

To the attention of users and technicians

180°

Fig.12

180°

Fig.13

Release

Lock

19

R

(OPTIONAL)

elease key with extractable cylinder

Release

Cod. 67411465 Rev.00 - 12/2012

Fig.14