8. The Hi-Shear Emlock may be wire to one of two different electrical configurations. An Auto Relock time delay

(standard with the 1565) is recommended for all installations to delay relocking 1 to 6 seconds after initial door closure.

This will help ensure the door is fully closed and at rest to obtain alignment before the Emlock is energized. Consult

Figure 7A or 7B according to material supplied.

With the power off make all wire connections to a properly fused power source.

9. When installing 1566 model use Figure 7B, make the timer adjustment as required and test the TDA time delay prior to

mounting in the frame. The TDA timer is field adjustable for 1 to 6 seconds and is factory set at approximately 3

seconds. Turn clockwise to increase and counter clockwise to decrease the delay time.

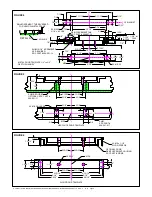

10. Install the Emlock and armature with the auto relock switch assembly towards the leading edge of the door.

11. For proper operation, the armature must be adjusted upward as close as possible and parallel to the Emlock without

interfering with opening and closing of the door. Proper operation cannot be expected with more than 1/8” clearance

between the armature and the Emlock. Use the hex key provided to adjust the armature vertical adjustment screw (the

allen head screws centered at both ends of the armature assembly). Turn counter clockwise to raise the armature.

12. With the door closed, turn the lock power on. Check the lateral alignment. The armature shear stops should be

centered between each pair of magnet shear stops.

13. If the clearance between the shear stops is sufficient, open and close the door a few times to ensure the Emlock will lock

and unlock positively.

14. Adjust the auto relock switch magnet to avoid early activation and help ensure positive locking on door closure. Adjust

inward to delay Emlock activation.

Do not

adjust higher than the armature rest position.

15. If the shear stops are too close or binding, double check the templating and door alignment, and make corrections as

required.

16. If positive locking cannot be attained due to misalignment after the previous adjustments, the armature shear stops can

be reversed with the wide clearance shear stops.

CAUTION: The use of armature offset shear stops may correct misalignment but should not be used when proper

door latching is inhibited.

17. Repeat steps 11 through 15 as necessary following shear stop replacement.

18. Cycle the door and Emlock several times after the completion of installation.

P:\INSTALLATION INST\ELECTROMAGNETIC LOCKS\INST-SHEAR 65-66\INST-SHEAR 65-66.vsd REV F 10-12 Page 2

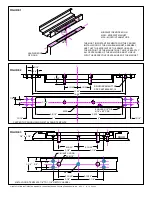

MODEL #

LOCK DIMENSION

L

W

D

10-7/116" 1-1/2”

1-5/8”

1565

1566

HOLDING

FORCE

10-7/16”

1-1/2”

1-1/4”

2700

2700

POWER

CONSUPTION

12VDC

800mA

800mA

400mA

400mA

24VDC

MODEL #

ITC

FTC

HTC

ARMATURE DIMENSION

L

W

D

11"

1-1/2”

1-1/2”

7/8”

7/8”

1-1/2”

7/8”

11"

11"