IN

AU

STRAL

IA

PR

OU

DLY BUILT

3

INSTRUCTIONS -

VIEWMASTER PRO

Projection Screen

Continued Over.../

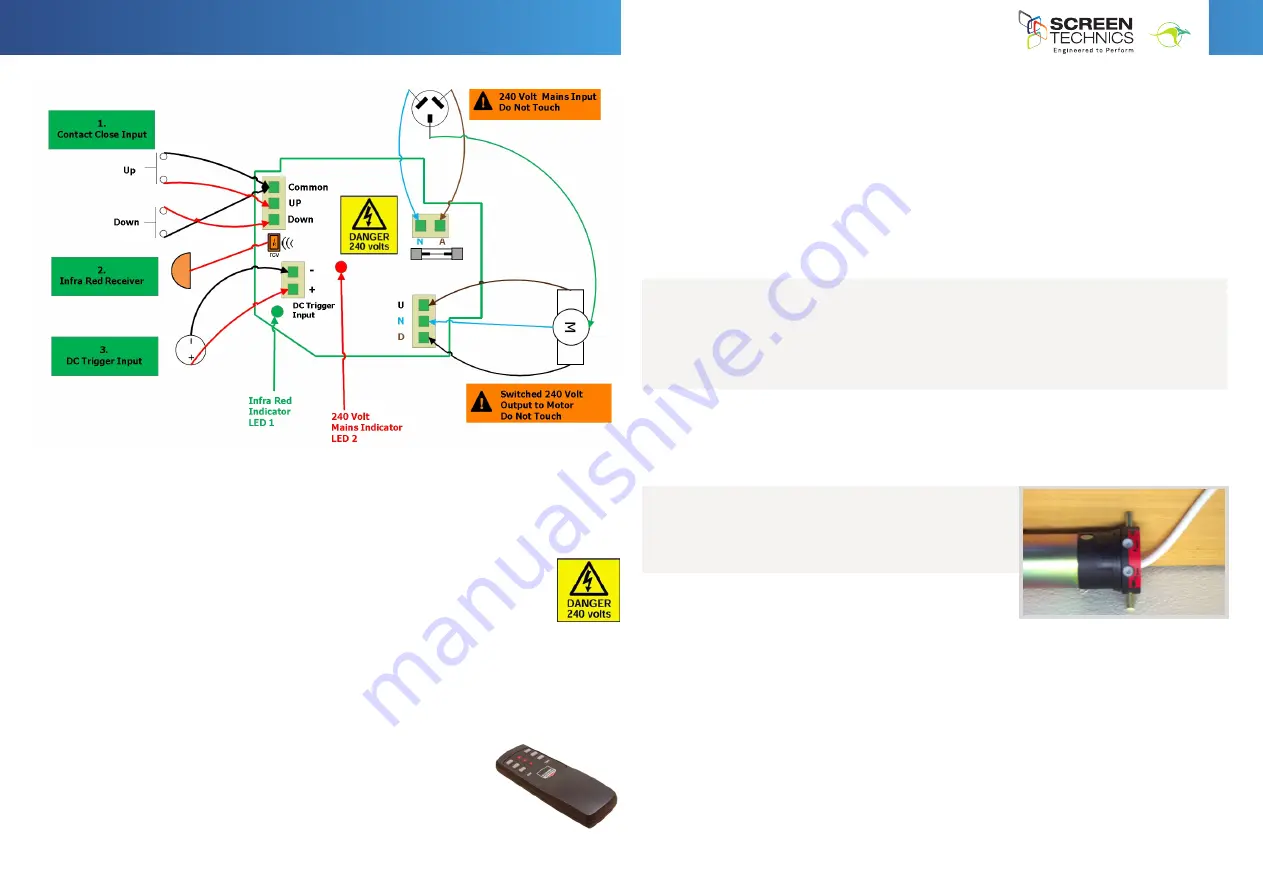

1. CONTACT CLOSE INPUT

•

No voltage, dry contact input

•

Requires momentary contact only

•

Contact is closed and opened between Up & Common – screen moves to up limit

•

Contact is closed and opened between Down & Common – screen moves to bottom limit

•

Stop command is sent when both Up & Down contact closed together

•

Motor reverses travel when opposite contact is closed – if moving down and up contact is

closed screen will stop and then reverse direction

•

Stop command is sent when both Up & Down contact closed together

2. INFRA-RED RECEIVER

•

Packaged with 300mm and 1.2 M lead from motor board to IR receiver

•

Packaged with standard 2 channel IR transmitter

•

Screen operates on group 1 & 2 on infra-red remote

•

Green LED 1 on motor board will flash when IR commands are received

3. DC TRIGGER INPUT

•

Down command is sent when a DC Voltage above 1.5 Volts @ 1mA minimum is applied to

trigger input

•

Up command is sent when a DC Voltage below 1.5 Volts @ 1mA minimum is applied to the

trigger input

•

Trigger input is polarity sensitive

•

DC voltage must not exceed 15 Volts DC

Note: The Viewmaster pro is equipped with automatic retraction after power failure, if power is

lost to the screen, the surface will retract to the up position when power is reconnected

MasterFit IP A, A+, B, B+, C, C+ Projection Screen

Thank you for purchasing a Screen Technics Projection Screen, please ensure that you read

the following instructions fully before installing this product.

The motor controller for the MasterFit range of projection screens is housed in an insulated

box and is packaged with a 1.2M IEC mains flex with moulded 3 pin plug and 240 volt output

to motor is supplied with a 4 pin WAGO connector with a 4M long 4 core flex allowing

placement flexibility.

1.

Contact Close Input

No voltage, dry contact input

Requires momentary contact only

Contact is closed and opened between Up & Common – screen moves to up limit

Contact is closed and opened between Down & Common – screen moves to bottom limit

Stop command is sent when both Up & Down contact closed together

2.

Infra-Red Receiver

Packaged with 300mm and 1.2 M lead from motor board to IR receiver

Packaged with standard 2 channel IR transmitter

Screen operates on group 1 & 2 on infra-red remote

Green LED 1 on motor board will flash when IR commands are received

Access to control board is on left hand side of projector screen case

Power must be removed before accessing inputs on control board

1.

Contact Close Input

No voltage, dry contact input

Requires momentary contact only

Contact is closed and opened between Up & Common – screen moves to up limit

Contact is closed and opened between Down & Common – screen moves to bottom limit

Motor reverses travel when opposite contact is closed – if moving down and up contact is closed

screen will stop and then reverse direction

Stop command is sent when both Up & Down contact closed together

2.

Infra-Red Receiver

Packaged with 300mm and 1.2 M lead from motor board to IR receiver

Packaged with standard 2 channel IR transmitter

Screen operates on group 1 & 2 on infra-red remote

Green LED on motor board will flash when IR commands are received

3.

DC Trigger Input

Down command is sent when a DC Voltage of 1.5 Volts @ 1mA minimum is applied to trigger input

Up command is sent when a DC Voltage below 1.5 Volts @ 1mA minimum is applied to the trigger input

Trigger input is polarity sensitive

DC voltage must not exceed 15 Volts DC

Note: The Viewmaster pro is equipped with automatic retraction after power failure, if power is lost to the

screen, the surface will retract to the up position when power is reconnected

Access to control board is on left hand side of projector screen case

Power must be removed before accessing inputs on control board

1.

Contact Close Input

No voltage, dry contact input

Requires momentary contact only

Contact is closed and opened between Up & Common – screen moves to up limit

Contact is closed and opened between Down & Common – screen moves to bottom limit

Motor reverses travel when opposite contact is closed – if moving down and up contact is closed

screen will stop and then reverse direction

Stop command is sent when both Up & Down contact closed together

2.

Infra-Red Receiver

Packaged with 300mm and 1.2 M lead from motor board to IR receiver

Packaged with standard 2 channel IR transmitter

Screen operates on group 1 & 2 on infra-red remote

Green LED on motor board will flash when IR commands are received

3.

DC Trigger Input

Down command is sent when a DC Voltage of 1.5 Volts @ 1mA minimum is applied to trigger input

Up command is sent when a DC Voltage below 1.5 Volts @ 1mA minimum is applied to the trigger input

Trigger input is polarity sensitive

DC voltage must not exceed 15 Volts DC

Note: The Viewmaster pro is equipped with automatic retraction after power failure, if power is lost to the

screen, the surface will retract to the up position when power is reconnected

Access to control board is on left hand side of projector screen case.

Power must be removed before accessing inputs on control board.

LIMIT SETTING FOR VIEWMASTER PRO SCREENS

The following instructions are for the adjustment of the limit switches that alter the upper

and lower stop positions on “Connect” ElectriCinema Screens only

WHERE ARE THE LIMIT SWITCHES?

(On the Left Hand Side).

One switch is accessible through the slat rod opening and the other is behind round cover plug

towards the front of the canister.

WHICH SWITCH IS FOR UP AND DOWN?

Down switch - Accessible through the round cover plug

Up switch - Accessible through the slat rod opening

WHAT TOOLS DO I NEED?

Either the limit setting tool (supplied), a narrow tip

screw driver (less than 4mm) or a 4mm Allen Key

RJ12 6 Core Straight Through Data cable can link up to 8 Connect controlled devices for multiple switching.

Low Voltage Trigger

Switches device upon the receipt of 3v to 24v DC from a projectors low volt output port, plugs into the phoenix

connector on the module.

Not polarity sensitive.

IP Control RJ45

Due to the detailed nature of the user instructions associated with this method of control we direct you to the

associated document – Electricinema IP Control Instructions V1.0

However for a beginners guide to basic control functions please download from

www.screentechnics.com.au

the PC Connect or Mac Connect software and this will assist you in identifying the Connect Module and provide

basic control, then guide you by web browser to communicate and program the individual Module.

Note: You will have to connect the screen module to a network to be able to utilise this software.

Note: As the Infra-Red control is also used to perform a Connect module reset in case you are troubleshooting any performance

issues, it is recommended that the IR cable be left attached to the module even if it is not the chosen operating method for your

installation.

Limit Setting for Connect ElectriCinema Screens

The following instructions are for the adjustment of the limit switches that alter the upper

and lower stop positions on "Connect" ElectriCinema Screens only

Where are The Limit Switches?

At the opposite end to the power cable (ie on the Right Hand Side).

One switch is accessible through the slat rod opening and the other is behind a rubber grommet

towards the front of the canister.

Which Switch is for Up and Down?

Down switch - Accessible through the rubber grommet

Up switch - Accessible through the slat rod opening

What Tools do I Need?

Either the limit setting tool (supplied), a narrow tip screw driver (less than 4mm) or a

4mm Allen Key

Which Way do I Turn the Switch?

Clockwise always increases the amount of rotation (travel) of the motor.

Anti-clockwise always reduces the amount of rotation (travel) of the motor.

So pick the switch responsible for the limit position, up or down. Clockwise turning of the switch will always let the motor travel

further in that direction. Anti-clockwise turning of the switch will lessen the amount of travel in that direction.

Can I adjust the switch while the screen is sitting on the limit - ie fully up or down?

Clockwise adjustment? – YES. But it is better to back the screen away from the limit and then adjust

Anti-clockwise adjustment? - NO you will damage the micro switch if you turn it anti-clockwise while the screen is sitting on the limit.

Never attempt this. You must back the screen away from the limit

before adjustment. After adjustment you will need to run the screen up and down to pick up the new limit

Will I void the product warranty if I damage the screen whilst making these adjustments?

Yes.