Charge Station Overview

59

SCOTT SAFETY

087-0067 REV A

For systems with an integral compressor, the operator can choose to turn Off the

compressor after filling the storage and then fill the breathing air cylinders. The Auto

Cascade system will provide the maximum number of fills before turning the

compressor back On.

Charge Station

Interfaces

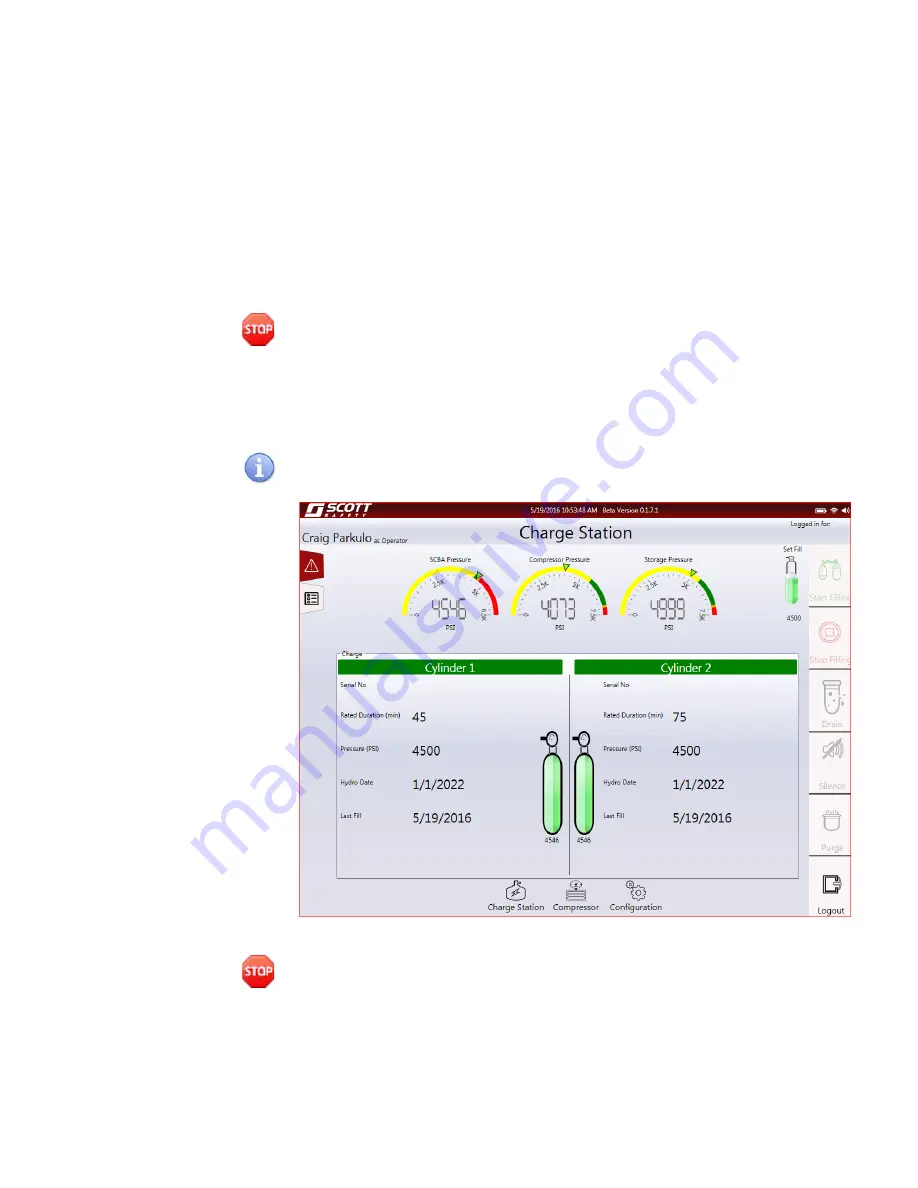

This section describes the different charge station interfaces. The operation of the

charge varies based on the model. The Scott models use a HMI to operate the charge

station. See

“Configuration and Setup” on page 21.

Other models do provide analog

gauges, but do not provide a touch pad controller.

Warning: When settings are changed, ensure those changes are communicated to all

affected personnel.

Depending on the configuration, the charge station may be controlled via the HMI. In

general, the HMI is used to start and stop the compressor and to provide information

about the compressors’ operation, performance and conditions to the operator.

shows an example of a charge station screen.

For more details,

“Configuration and Setup” on page 21.

Figure 30

Charge Station Screen Example

Warning: When settings are changed, ensure those changes are communicated to all

affected personnel.

Summary of Contents for HushAir Connect 7500

Page 1: ...User Guide 087 0067 Rev A HushAir Connect 7500 COMPRESSOR SYSTEM ...

Page 2: ......

Page 3: ...HushAir Connect 7500 User Guide COMPRESSOR SYSTEM 087 0067 Rev A ...

Page 8: ...IV CONTENTS 087 0067 REV A SCOTT SAFETY ...

Page 12: ...X LIST OF TABLES 087 0067 REV A SCOTT SAFETY ...

Page 42: ...20 CHAPTER 2 INSTALLATION 087 0067 REV A SCOTT SAFETY ...

Page 73: ...Configuring the System 51 SCOTT SAFETY 087 0067 REV A Figure 27 Override Status Screen ...

Page 106: ...84 CHAPTER 5 MAINTENANCE 087 0067 REV A SCOTT SAFETY Figure 48 Oil Drain Location 3 1 2 ...

Page 112: ...90 APPENDIX A SPECIFICATIONS 087 0067 REV A SCOTT SAFETY ...

Page 119: ......