ScopeDome.com

2010 Slupsk - Poland

Shutter drive assembly

A

C

B

D

E

Fig. 10 - Encoder module on motor axis

A. Dome's side panel

B. Base ring.

C. Shield holder/support

D. Home sensor magnet

E. Home sensor contractron

F. Encoder module

page 7

G

F

E

D

F

C

B

A

G

H

I

J

J

K

L

M

L

B

A

C

M

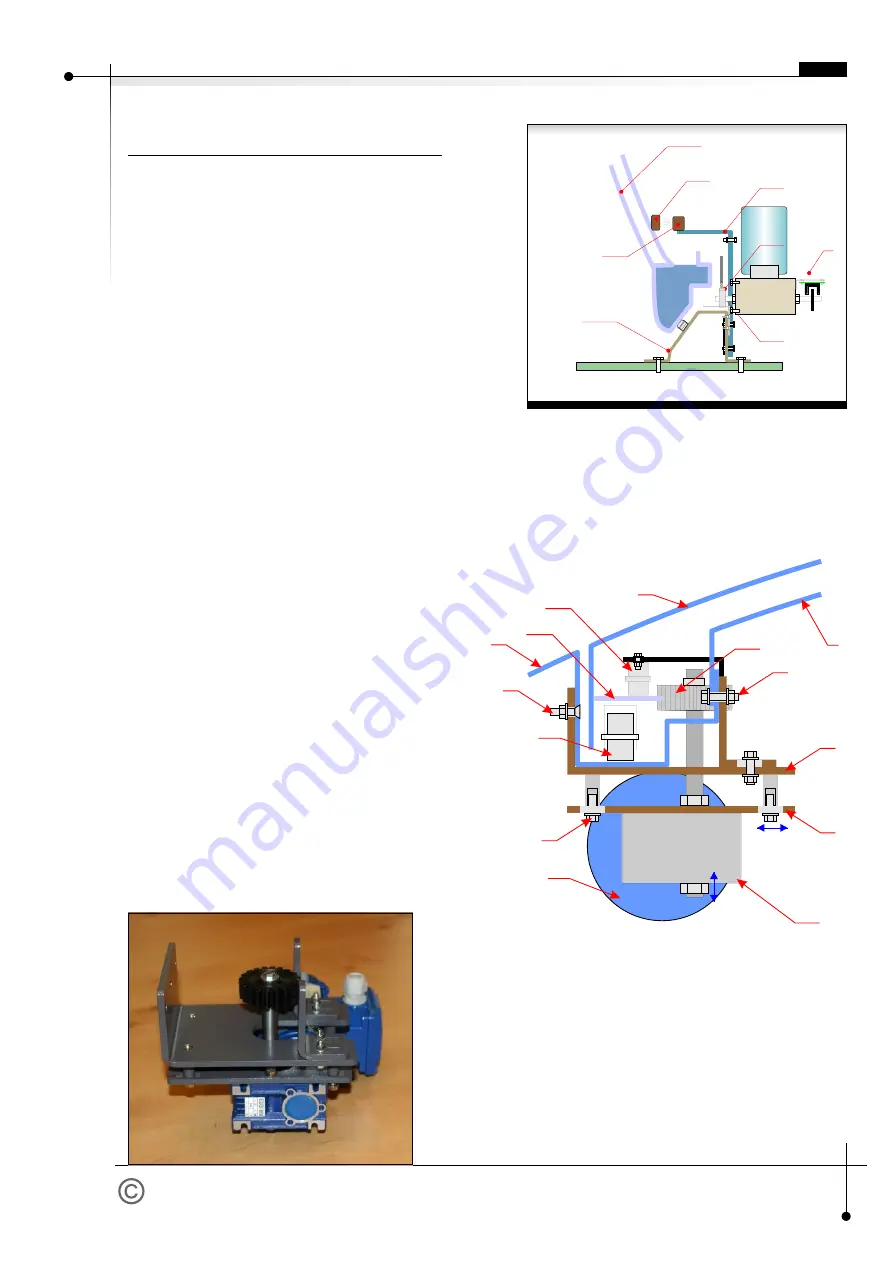

Fig. 11 - Shutter drive.

A. Motor/Engine

B. Motoreductor (i=80)

C. Cog-wheel

D. Shutter holder roller

E. Cog-rim

F. Shutter's main roller

G. Dome's side panel

H. Shutter panel

I.

Dome's back panel

J. Bolts/Screws fastening the motor

K. Roller pressure adjustment screws

L. Motor main holder

M. Motor module support.

fig. 12 - Shutter drive.

Shutter drive assembly

Action sequence.

1. Screw on motor main holder (L) at dome's top with

the use of five screws.

2. Fix the cog-wheel (C) in drive motor module (M).

3. Screw on slightly drive motor with main shutter

holder in a way that the cog-wheel would not touch

shutter's cog-rim.

4. Adjust cog-wheel height so that cog-rim is at its

middle point.

5. Fix end switches.

6. Test limit switches operation trying to set them active

at approx. 2cm before full open/close of the shutter.

7. Press and tighten cog-wheel to shutter's cog-rim and

screw on the bolts (K) fastening motor module.

8. Install motor and limit switches wiring.

9. Open and close the shutter several times using

ScopeDome USB Card.

10. If the cog-wheel slips off cog-rim - stop the shutter at

this point. Loosen screws fastening the motor

module, then tighten the cog-wheel to cog-rim hitting

2X motor mounting plate with a hammer. Next screw

on firmly four bolts fastening the motor module.

11. Test shutter drive operation again.

12. Check if the shutter power cable does not brush

dome's engine during its revolution.

Shutter motor is powered by 14-core cable. Its both ends

shall be fixed firmly - as not to be teared out if the dome

proceeds too many turns. The cable shall be placed in a

way it would not brush the dome's engine.

EN

F