4 OF 6

F. DAILY USE

a. If using flexible tubing, attach the ends of the tubing to the tanks. In the absence of an appropriate slot,

solidly grasp the delivery tube before pumping.

b. Before starting the pump, make sure that the delivery valve is closed (dispensing nozzle or line valve).

c. Turn the ON/OFF switch to ON. The by-pass valve allows functioning with the delivery closed only for brief

periods.

d. Open the delivery valve, solidly grasping the end of the tubing.

e. Close the delivery valve to stop dispensing.

f. When dispensing is finished, turn off the pump.

ATTENTION!

Function with the delivery closed is only allowed for brief periods (2-3 minutes maximum).

After using, make sure the pump is turned off.

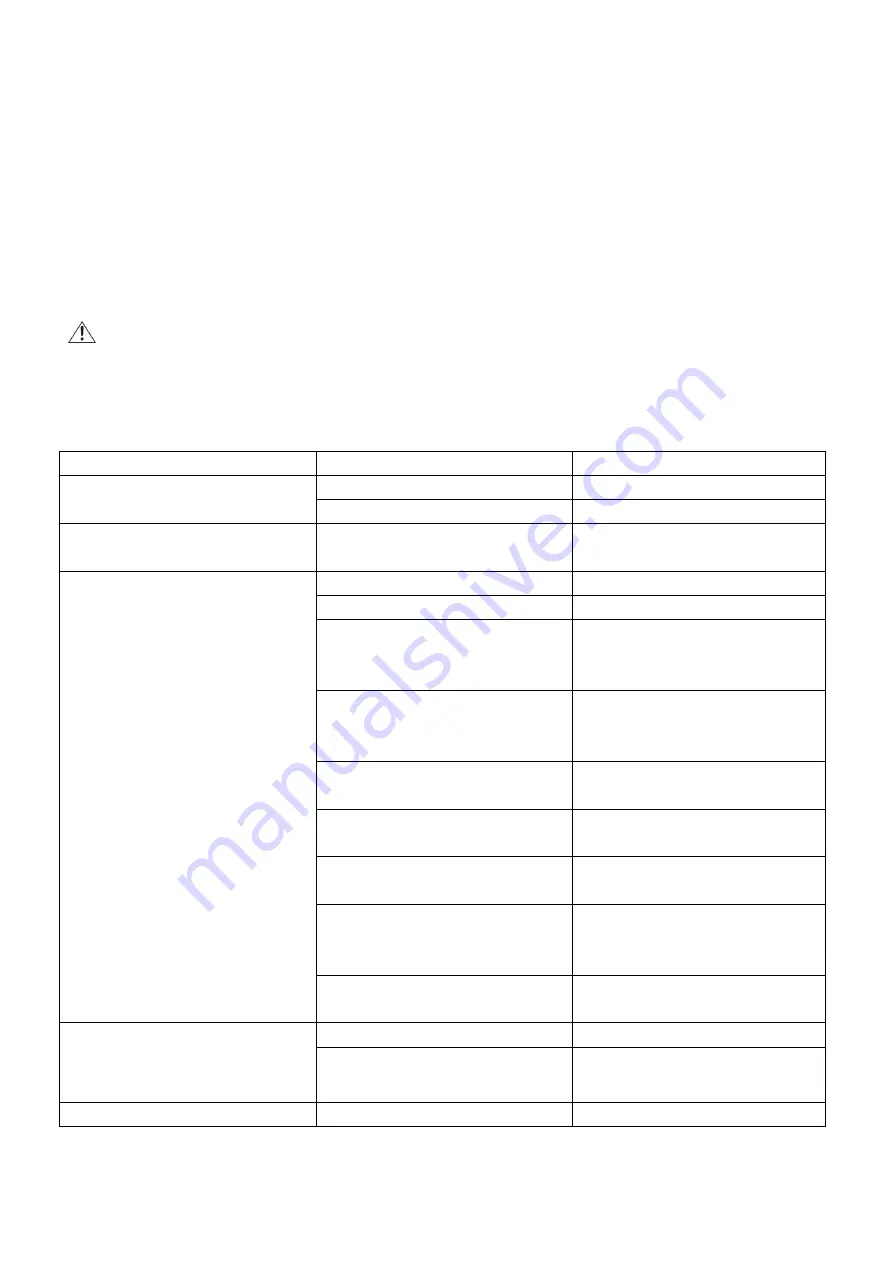

G. PROBLEMS AND SOLUTIONS

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

The Motor is not turning

Lack of electric power

Check the electrical connecting

Motor Problems

Contact the Service Department

The motor turns slowly when

starting

Low voltage in the electric power

line

Bring the voltage back within the

anticipated limits

Low or no flow rate

Low level in the suction tank

Refill the tank

Filter clogged

Clean the filter

Excessive suction pressure

Lower the pump with respect to

the level of the tank or increase

the cross-section of the tubing

High loss of head in the delivery

circuit (working with the by-pass

open)

Use shorter tubing or of greater

diameter

By-pass valve blocked

Dismantle the valve, clean and/or

replace it.

Air entering the pump or the

suction tubing

Check the seals of the

Connections

A narrowing in the suction tubing

Use tubing suitable for working

under suction pressure

Low rotation speed

Check the voltage at the pump.

Adjust the voltage and/or use

cables of greater cross-section

The suction tubing is resting on

the bottom of the tank

Raise the tubing

Increased pump noise

Cavitation occurring

Reduce suction pressure

Irregular

functioning

of

the

by-pass

Dispense fluid until the air is

purged from the by-pass system

Leakage from the pump body

Diaphragm damaged

Check and replace the diaphragm