Maintenance and care

02.00|WDB 99 |en

51

Maintenance and care for WDA 99-79-32 hydraulic

compensation module

Only store the hydraulic expansion toolholder when it is not

clamped and make sure to protect it from corrosion.

• To secure the clamping forces with every clamping pin change,

clean the clamping bore and the screw-shaped groove with a

cleaning agent containing solvents.

• For storage, lightly oil the entire surface of the hydraulic

expansion toolholder.

It may be necessary for it to be cleaned according to the ambi-

ent conditions, especially in the case of high clamping frequen-

cies, high operating temperatures, or abrasive dirt or metal

clips and metal particles.

Repair work is only allowed to be carried out at a SCHUNK site.

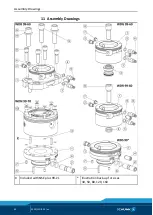

Ambient conditions and operating conditions

• Make sure that the contact surfaces of the interface are always

clean.

• Always ensure that no chips of any kind enter the interface of

the change components.

• Only use high-quality cooling emulsions with anti-corrosive

additives during processing.

• Check the pneumatic clamping systems and the workpiece

direct clamping modules at regular intervals (at least every

2 weeks or after 200 clampings).

• Carry out regular visual/functional checks.

In the case of visible damage or signs of malfunctions on the

clamping systems or the quick-change pallet system installed with

the WDN 99-70 workpiece direct clamping module, shut down the

clamping systems immediately. The system may only be commis-

sioned again once the faults have been corrected. For example, by

replacing the damaged module.

8.1

8.2