Assembly

02.00 | GWB | Assembly and Operating Manual | en | 389122

23

4.1.2 Pneumatic connection

CAUTION

Damage to the gripper is possible!

If the maximum permissible finger weight or the permissible

mass moment of inertia of the fingers is exceeded, the gripper

can be damaged.

•

A jaw movement always has to be without jerks and bounce.

•

You must therefore implement sufficient reduction and/or

damping.

•

Observe the diagrams and information in the catalog data

sheet.

NOTE

• Observe the requirements for the compressed air supply,

18].

• In case of compressed air loss (cutting off the energy line), the

components lose their dynamic effects and do not remain in a

secure position. However, the use of a SDV-P pressure

maintenance valve is recommended in this case in order to

maintain the dynamic effect for some time. Product variants

are also offered with mechanical gripping force via springs,

which also ensure a minimum clamping force in the event of a

pressure drop.

•

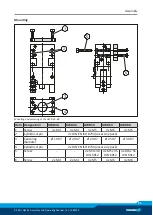

Hose-free direct connection:

Optionally to ground or to front.

• Remove the M3 set-screws (21) from the selected direct

connections and close the lateral hose connections with the M5

locking screws supplied.

• Use the O-rings Ø 3 x 1.5 supplied in the accessory kit.

• Integrate the one-way flow control valves at a suitable place in

the gripper's pressure supply. Observe the circuit diagram in the

process (exhaust throttling).

CAUTION

Adjust the speed of the gripper using the one-way flow control

valves to allow the gripper to open and close smoothly without

jerking.