4

Operating instructions

Safety-monitoring module

EBW-AZ

EN

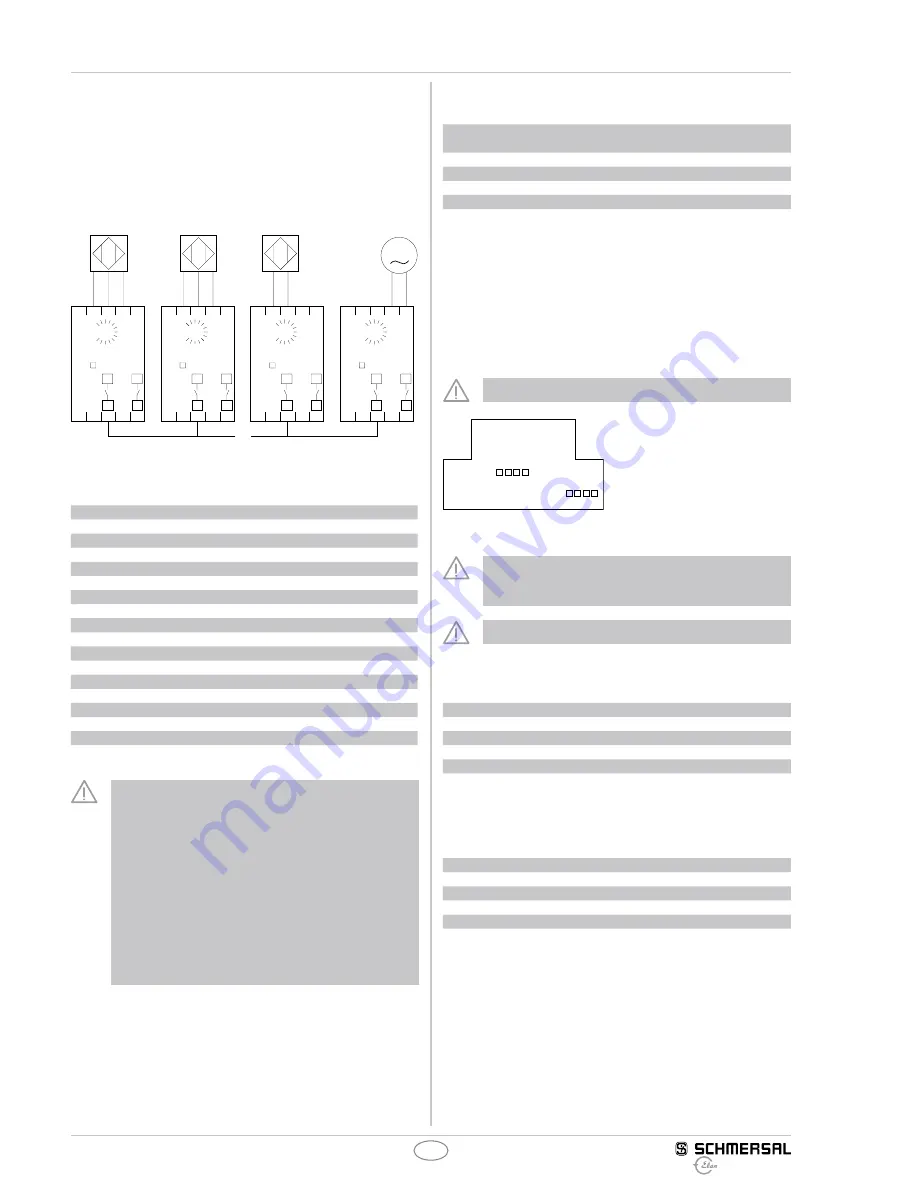

Wiring possibilities (Fig. 3 and 4)

• All commercially available generators with NPN, PNP, NAMUR

and SINUS signals can be connected.

•

An adjustment to the generator type regarded is provided internally

in the device, optionally this can be done in factory or according to

setting instructions.

•

The control command of the relay contacts is not saved, i.e. the

upper or lower limit of the limit value being exceeded causes a

status change of the positive-guided output contacts.

A1

24V

IN

0V

TG

A2

13

14

21

22

14

22

13

21

EBW-AZ-24V

Typ:

DZW

SSW

100%

10%

Rel.

U

B

A1

24V

IN

0V

TG

A2

13

14

21

22

14

22

13

21

EBW-AZ-24V

Typ:

PNP

NPN

b)

NAMUR

a)

DZW

SSW

100%

10%

Rel.

U

B

A1

24V

IN

0V

TG

A2

13

14

21

22

14

22

13

21

EBW-AZ-24V

Typ:

DZW

SSW

100%

10%

Rel.

U

B

A1

24V

IN

0V

TG

A2

13

14

21

22

14

22

13

21

EBW-AZ-24V

Typ:

DZW

SSW

100%

10%

Rel.

U

B

Fig. 3

a) Tacho

b) Potential-free output contacts

Proximity switch PNP

Voltage range:

U

max.

30 VDC (< 4.0 V … > 4.5 V)

Signal load:

approx. 18 mA (at U

B

24 VDC)

Frequency range:

< 100 kHz

Proximity switch NPN

Voltage range:

U

max.

30 VDC (< 4.0 V … > 4.5 V)

Signal load:

approx. 18 mA (at U

B

24 VDC)

Frequency range:

< 100 kHz

NAMUR

Voltage range:

U

max.

30 VDC (< 4.0 V … > 4.5 V)

Signal load:

approx. 9 mA (at U

B

24 VDC)

Frequency range:

< 100 kHz

Tachogenerator

Voltage range:

U

max.

44 VAC (effective)

Signal load:

approx. 9.0 mA (at U

B

44 VAC

eff.

)

Frequency range:

< 100 kHz

"signal recognition" (min.):

approx. 1.44 VAC 4.66 Hz

Fig. 4

Due to the specific design of the EBW devices as standstill

monitor, it must be observed that a control command does

not trigger a restart interlock, i.e. if necessary, a special ON

or RESET signal must be otherwise realised in the electrical

safety circuit, if this is required prior to a restart.

For the definition of the mouvement limit value to be monitored,

the device setting versions furthermore must be observed.

In addition to that, it must be ensured that any incidental or

manipulative alteration of the frontal set-up potentiometer or the

change-over switch of the EBW-AZ devices to EN 292 is preven-

ted or does not lead to a hazardous situation. If the customer is

unable to fulfil this condition, the use of the EBW-WB devices,

which have no external setting devices, is recommended.

Adjustment

In factory or by the customer

Frequency range

PNP/

Namur

NPN

Tacho

Jumper

0.08 … 1 Hz

1

5

9

B4

0.8 … 10 Hz

2

6

10

B3

8 … 100 Hz

3

7

11

B2

80 Hz … 1 kHz

4

8

12

B1

Jumper

1 + 3

2 + 3

4

–

Fig. 5: Type classification

(example: frequency range 8...100Hz, signal generator PNP sensor = type 3)

Opening the enclosure

Necessary to adjust the solder straps located on the circuit board

of the device (Fig. 6).

To this effect, carefully separate the bottom part of the enclosure

from the upper part by means of a suitable tool.

Do not open the device when live!

J1

J2

J3

J4

B1

B2

B3

B4

Fig. 6: lateral view of the left circuit board of the device, programming

by solder straps

When the enclosure is open, the electrostatic discharge

requirements must be respected and observed. After the

setting is completed, the enclosure must be closed again.

Only touch the components after electrical discharge!

Adjust the solder straps J1...J4 to the sensor (Fig. 7)

PNP/Namur

NPN

Tacho

J1

×

J2

×

J3

×

×

J4

×

Fig. 7

Adjust the solder straps B1...B4 to the required frequency

range (Fig. 8)

Hz

Right hinged (approx. 10%) Left hinged (approx. 100%)

B4

0.08 Hz

1 Hz

B3

0.8 Hz

10 Hz

B2

8 Hz

100 Hz

B1

80 Hz

1,000 Hz

Fig. 8