6

Operating instructions

Control panel with emergency stop

BDF200-SD

BDF200-FB

EN

6. Diagnostic functions

6.1 Diagnostic functions of SD interface

Safety switchgear devices with serial diagnostic cable have a serial

input and output instead of the conventional diagnostic output If these

safety switchgear devices are wired in series, the safety channels as

well as the inputs and outputs of the diagnostic channels are wired in

series

Up to 31 safety switchgear devices can be connected in series with

serial diagnostics For the evaluation of the serial diagnostics line either

the PROFIBUS-Gateway SD-I-DP-V0-2 or the Universal-Gateway

SD-I-U- are used This SD-Gateway is integrated as a slave in an

existing field bus system In this way, the diagnostic signals can be

evaluated by means of a PLC

The necessary documentation for the integration of the SD-Gateway is

available for download at wwwschmersalcom

The query details for each safety sensor are transmitted to the device

via one output byte of the PLC respectively

The request data for each safety sensor are transmitted to the device

through an output byte of the PLC

Should a communication error occur between the SD Gateway and the

safety switchgear, the safety switchgear retains its switch status for the

safety outputs

Diagnostic error warning and error

If an error (warning) is signalled in the response byte, detailed fault

information can be read out

Detailed information about the use of the serial diagnostics can be

found in the operating instructions of the PROFIBUS-Gateway

SD-I-DP-V0-2 and the Universal-Gateway SD-I-U-….

Error warning

A fault has occurred, which causes the safety outputs to be disabled

after 30 minutes The safety outputs initially remain enabled

This enables the shutdown of the process in a controlled manner

An error warning is deleted when the cause of error is eliminated

Error

A fault has occurred, which causes the safety outputs to be disabled

The fault is reset, when the cause is eliminated and bit 7 of the query

byte changes from 1 to 0 or the emergency stop is pressed again

Faults at the safety outputs are only deleted upon the next release,

as the fault rectification cannot be detected sooner

On the FB variant of the BDF200-SD/FB, the two diagnosis

bytes 'Error warnings' and 'Error messages' are not

transferred

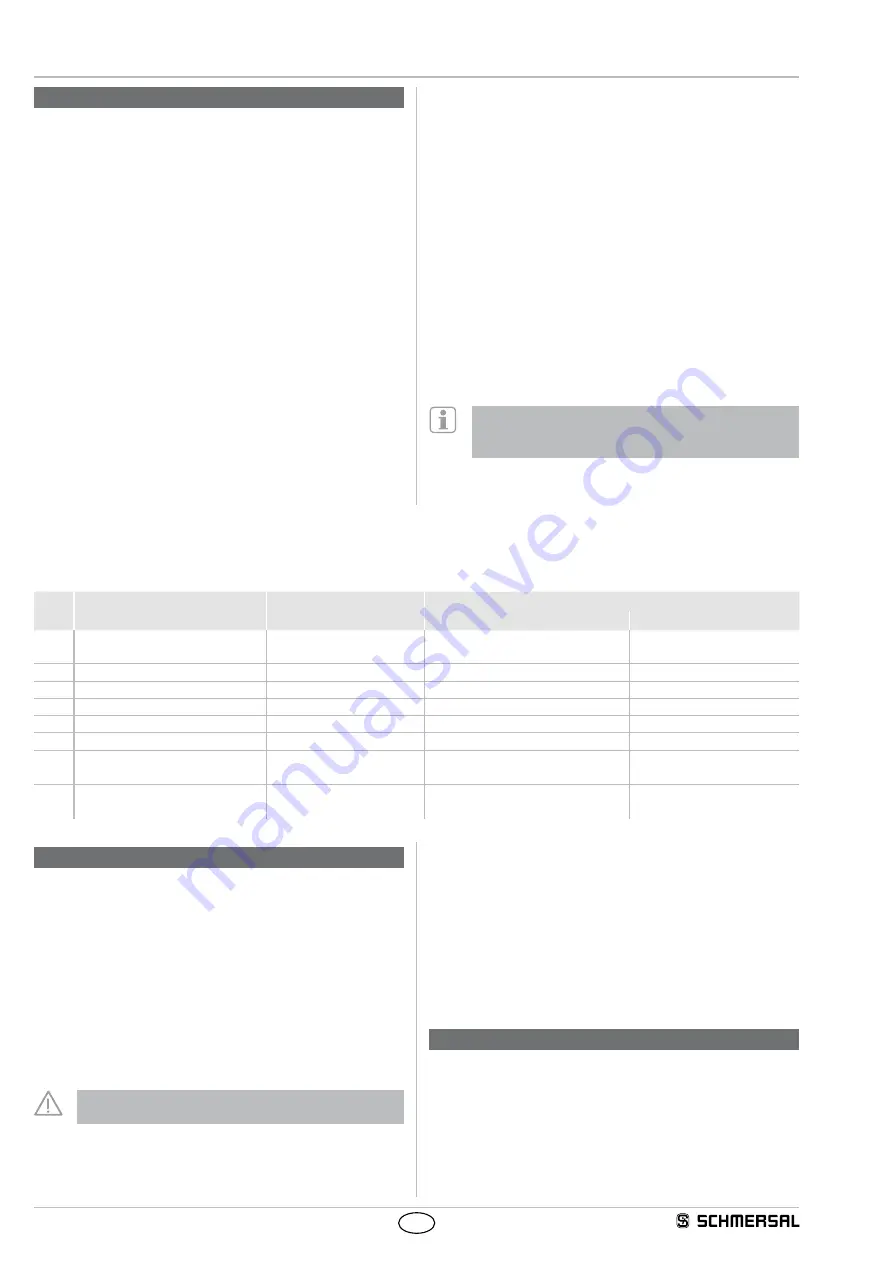

Table 1: Overview of status signals, warnings or error messages of SD variant

Communication directions: Request byte:

From PLC to local safety switchgear

Response byte:

From local safety switchgear to PLC

Warning/error byte:

From local safety switchgear to PLC

Bit n° Request byte

Response byte

Diagnostic

Error warnings

Error messages

Bit 0: —

Safety output

emergency stop switched on

Error output Y1

Error output Y1

Bit 1: LED G24 red

NO contact from

pos 2

Error output Y2

Error output Y2

Bit 2: LED G24 green

NC contact from

pos 2

Cross-wire Y1/Y2

Cross-wire Y1/Y2

Bit 3: LED illuminated push button pos 2 NO contact from

pos 3

Temperature too high

Temperature too high

Bit 4: LED illuminated push button pos 3 NC contact from

pos 3

—

Error emergency stop button

Bit 5: LED illuminated push button pos 4 NO contact from

pos 4

Internal device error

Internal device error

Bit 6: —

Error warning

Communication error between field

bus Gateway and SD slave

—

Bit 7: Error reset

Error

(enabling path switched off)

Operating voltage limit

—

7. Set-up and maintenance

7.1 Functional testing

The safety function of the safety components must be tested

The following conditions must be checked and met:

• Correct fixing of the fitted component

• Check the integrity of the cables and connections

• Check the command and signalling devices for damage

• For the types with extension …-2875, the proper fitting and the

smooth operation of the pushbuttons must be checked after the

installation of the pushbutton and illuminated pushbutton caps

7.2 Maintenance

The function of the emergency stop button must be tested in regular

intervals

Maintenance:

Please observe that the safety function must

be triggered at least once a year to test the system!

In case of correct installation in accordance with the instructions

described above, the component requires little maintenance Under

extreme conditions, we recommend routine maintenance as follows:

• Check the correct fixing of the control panel

• Remove particles of dust and soiling

• Check the integrity of the cables and connections

• For the types with extension …-2875, the smooth operation of the

pushbuttons and the illuminated pushbuttons must be checked

Damaged or defective components must be replaced.

8. Disassembly and disposal

8.1 Disassembly

The safety switchgear must be disassembled in a de-energised

condition only

8.2 Disposal

The safety switchgear must be disposed of in an appropriate manner in

accordance with the national prescriptions and legislations