5

BDF 200 AS

Operating instructions

Control panel with emergency stop

EN

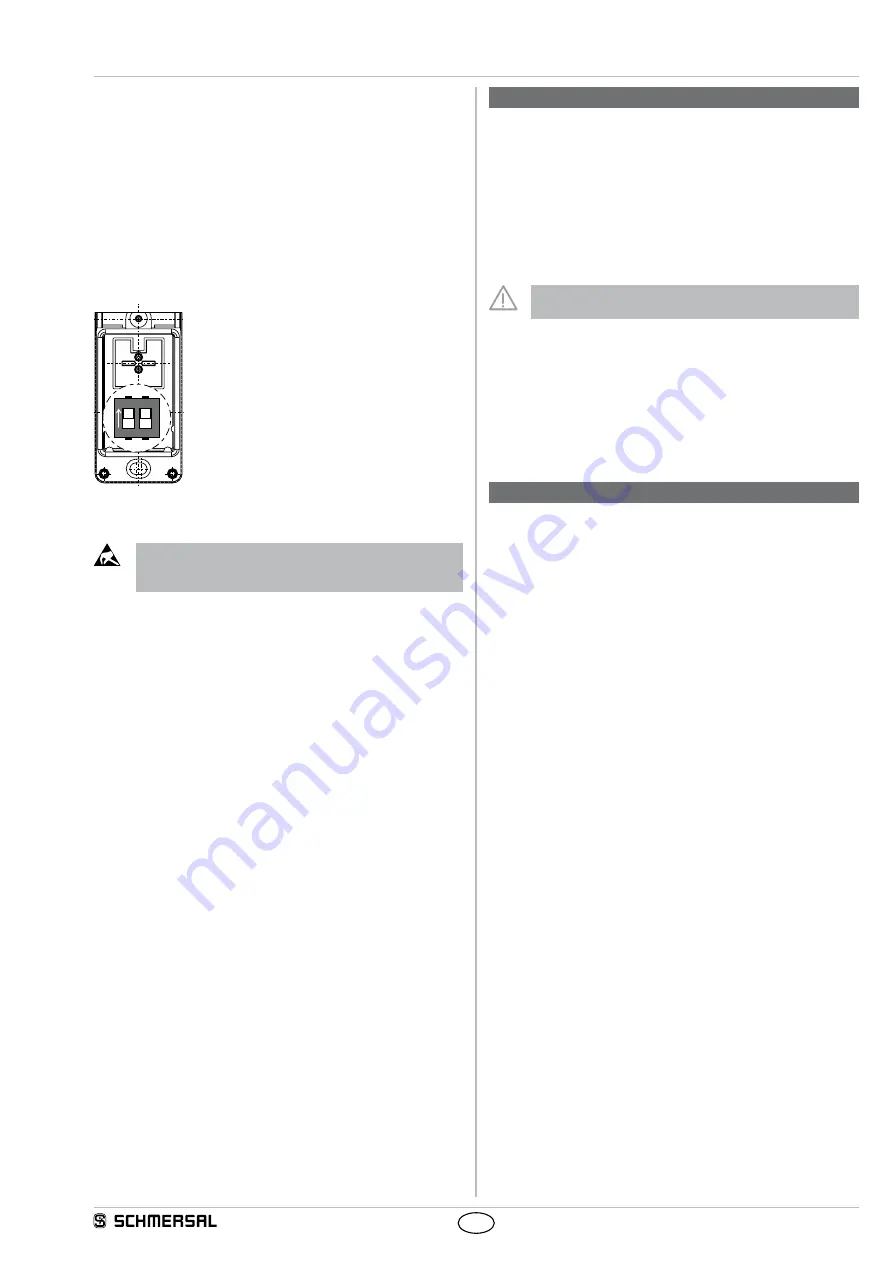

5.5 Programming the slave address

The slave addresses for both integrated

AS-i slaves are programmed through the M12 connector

To that effectn the lower enclosure cover must be opened By means

of the there-located DIP switches, both AS-i slaves can be individually

separated from or connected to the AS-i connection

• DIP-SW 1

AS-i A/B-Slave

• DIP-SW 2

AS-i Safety-Slave

For the AS-i Safety-Slave an address from 1 to 31 and for the AS-i A/B

slave an adress from 1A to 31B can be set by means of an AS-i bus

master or a hand-held programming device

ON

1

2

DIP-SW 1:

AS-i A/B-Slave

DIP-SW 2: AS-i Safety-Slave

Caution!

Do not touch electrostatically loaded elements

Do not touch the printed circuit board

5.6 Status signal "safety release"

The "safety release" status signal from a Safety at Work slave can be

cyclically queried by the control system through the AS-i master To

thiseffect, the 4 input bits with the varying SaW code of a Safety at

Work slave are evaluated through an OR operation with 4 inputs in the

control system

6. Set-up and maintenance

6.1 Functional testing

The safety function of the safety components must be tested The

following conditions must be checked and met:

• Correct fixing of the fitted component

• Check the integrity of the cables and connections

• Check the command and signalling devices for damage

6.2 Maintenance

The function of the emergency stop button must be tested in regular

intervals

Maintenance:

Please observe that the safety function must

be triggered at least once a year to test the system!

In case of correct installation in accordance with the above-described

instructions, the component requires little maintenance Under extreme

conditions, we recommend routine maintenance as follows:

• Check the correct fixing of the control panel

• Remove particles of dust and soiling.

• Check the integrity of the cables and connections

Damaged or defective components must be replaced.

7. Disassembly and disposal

7.1 Disassembly

The safety switchgear must be disassembled in a de-energised

condition only

7.2 Disposal

The safety switchgear must be disposed of in an appropriate manner in

accordance with the national prescriptions and legislations