4

Operating instructions

Solenoid interlock

AZM400

EN

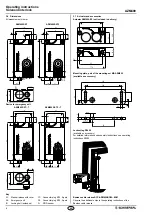

3. Mounting

3.1 General mounting instructions

Please observe the relevant requirements of the standards

ISO 12100, ISO 14119 and ISO 14120.

Any mounting position.

The accumulation of fine-grained contamination in the area of the bolt is

to be prevented.

In such a case it is therefore not advised to have vertical mounting,

where the bolt goes upwards from below.

For the correct fixing of the solenoid interlock, the device is provided

with two mounting holes for M6 screws.

The M6 screws should have at least the strength class 10.9.

The tightening torque of the M6 screws is 8 Nm.

The safety component and the actuator must be permanently

fitted to the safety guards and protected against displacement

by suitable measures (tamperproof screws, gluing, drilling,

pinning).

Actuating directions and switch distances

The AZM400 can be operated within the following tolerance limits:

X – axis: ± 4 mm

Y – axis: ± 4 mm

Z – axis: Distance between actuator and solenoid interlock 1…7 mm

with max. angle offset of 2°

The actuating curves show the typical detection range of the

actuator depending on the actuating direction.

~-26

~+10

~+26

~-10

0

[mm]

0

~+18

~18

[mm]

X

Y

1

...

7

mm

±

4 mm

Z

±

4 mm

The approach direction must only be from the X and Y

directions.

The maximum distance of 7 mm between the actuator

and the solenoid interlock must be maintained so that the

stipulated clamping force and the safe clamping function is

achieved according to SIL 3.

The construction of the guard door is to be designed so that it

is not possible to move the guard system with the actuator on

the Z axis so far that the distance between the interlock and

the actuator is greater than 7 mm.

The safety equipment must be designed so that there is no

crushing hazard due to the movement of the bolt.

Mounting of the solenoid interlock and the actuator

Refer to the mounting instructions manual for the corresponding

actuator.

To avoid any interference inherent to this kind of system and any

reduction of the switching distances, please observe the following

guidelines:

• Metal parts and magnetic fields near the safety interlock can affect the

switching distance.

• Keep away from metal chips.