7

AZM 200

Operating instructions

Solenoid interlock

EN

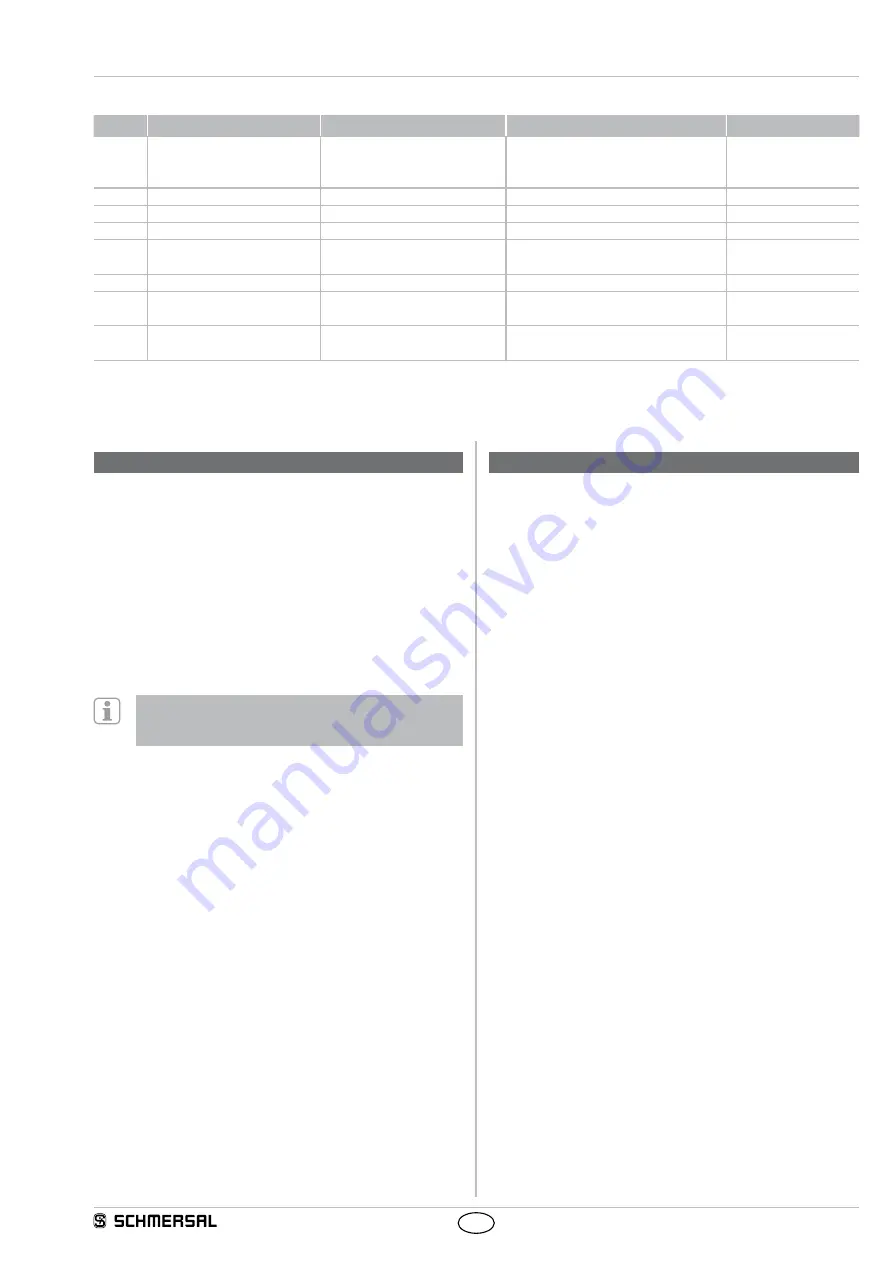

Table 3: I/O data and diagnostic data

Bit n°

Request byte

Response byte

Diagnostic error warning

Diagnostic error

Bit 0:

Magnet in, irrespective of

power to lock or power to

unlock principle

Safety output activated

Error output Y1

Error output Y1

Bit 1:

---

Actuator detected

Error output Y2

Error output Y2

Bit 2:

---

Actuator detected and locked

Cross-wire short

Cross-wire short

Bit 3:

---

---

Temperature too high

Temperature too high

Bit 4:

---

Input condition X1 and X2

---

incorrect or

defective actuator

Bit 5:

---

Guard door detected

Internal device error

Internal device error

Bit 6:

---

Error warning

1)

Communication error between the field

bus Gateway and the safety switchgear

---

Bit 7:

Error reset

Error

(enabling path switched off)

Operating voltage too low

---

1)

after 30 min -> fault

The described condition is reached, when Bit = 1

7. Set-up and maintenance

7.1 Functional testing

The safety function of the safety components must be tested.

The following conditions must be previously checked and met:

1. Fitting of the solenoid interlock and the actuator

2. Check the integrity of the cable entry and connections

3. Check the switch enclosure for damage

7.2 Maintenance

We recommend a regular visual inspection and functional test, including

the following steps:

1. Check for tight installation of the actuator and the switch

2. Remove particles of dust and soiling

3. Check cable entry and connections

Adequate measures must be taken to ensure protection

against tampering either to prevent tampering of the safety

guard, for instance by means of replacement actuators.

Damaged or defective components must be replaced.

8. Disassembly and disposal

8.1 Disassembly

The safety switchgear must be disassembled in a de-energised

condition only.

8.2 Disposal

The safety switchgear must be disposed of in an appropriate manner

in accordance with the national prescriptions and legislations.