28

PROCAT

MAINTENANCE

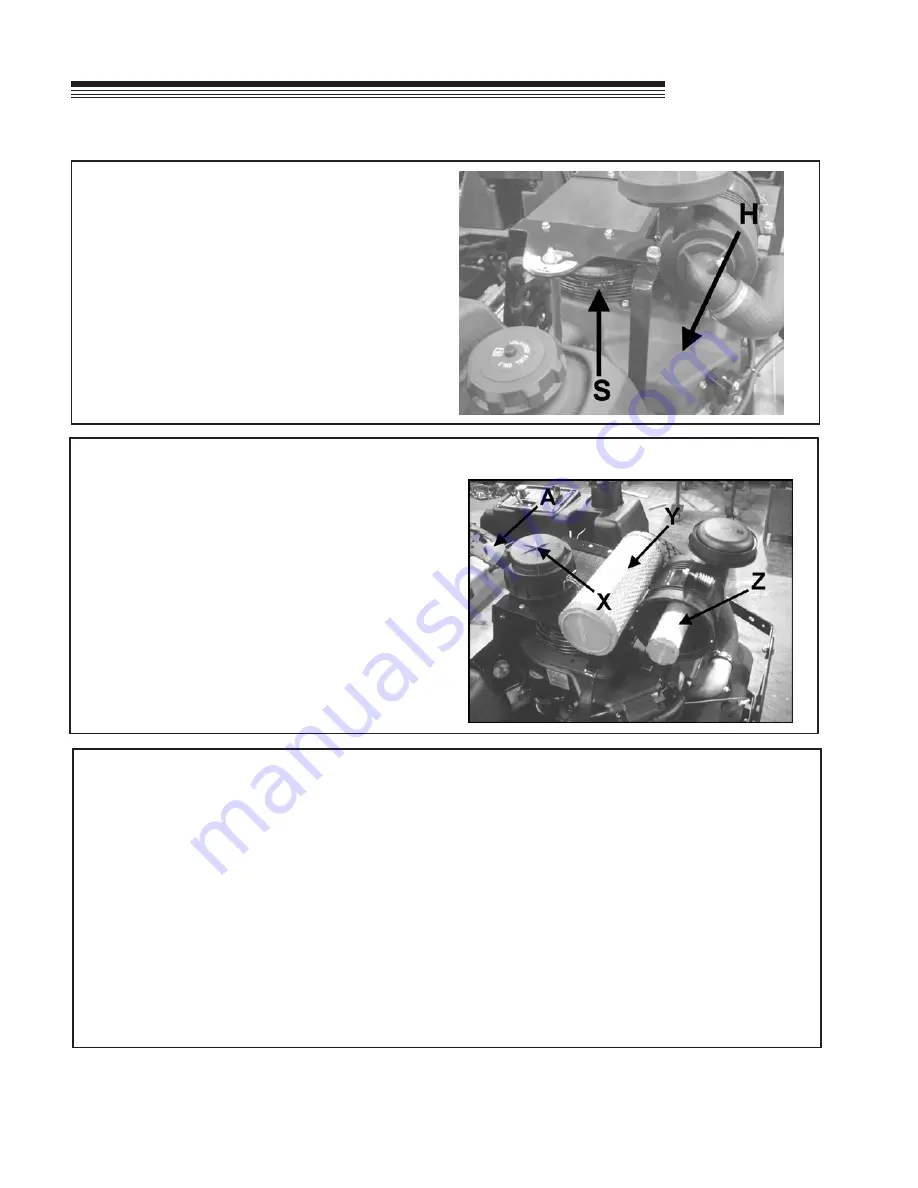

HEAVY DUTY CYCLONIC AIR CLEANER

Clean and replace the air cleaner element as

specified in the service chart. Uneven running, lack

of power or black exhaust fumes may indicate a dirty

air cleaner.

To replace air cleaner elements:

1. Unclamp end cover

X

and remove existing

cleaner elements.

2. Insert new elements

Y

and

Z

and replace cover.

Ensure the breathing port

A

is pointing down and

towards the front of the tractor.

ENGINE COOLING

Continued operation with a clogged cooling system

will cause severe overheating and can result in en-

gine damage.

-

Daily

: Clean air intake screen

S

on air cooled

engines.

-

Every 100 hours

: Clean cooling fins beneath

blower housing

H

with reference to information in

the engine manufacturer's manual.

CLEANING MACHINE

Clean the machine after use. The machine will run

cooler and last longer if kept free of clippings and

other debris. A clean machine also reduces the risk

of fire due to accumulation of combustible debris and

chaff

Brush or blow clippings and debris off the cutterdeck

and engine deck.

WASHING MACHINE

CAUTION: Improperly washing a machine can cause

water to enter bearings and other components. This

can greatly reduce component life.

–

Do not use a pressure washer. Do not direct

water at bearings or seals. High pressure water

can blow past seals ad enter seal bearings.

–

Allow the machine to cool down before washing.

Water on a warm machine can be sucked into

sealed bearings as they cool.

–

Avoid getting electrical connections wet. Water

can cause electrical faults and corrosion of elec-

trical components.