Commissioning

Before commissioning, be aware of the

safety notices.

All protective and auxiliary

equipment must be attached.

Carry out work such as re-tooling, adjusting,

measuring and cleaning only when the motor

is switched off.

Disconnect the mains plug!

Motor brake:

Before operation, test the run down time, it

should be less than 10s.

Practical example - dressing fig. 5 + 6

Warning! Never work with a jointer without the

cutterblock cover.

Jointer work – takeoff fig. 7

During jointer work, the takeoff can be

adjusted from 0 – 3 mm via the table

adjustment lever (5).

Warning! Loosen the locking handle (6)

first when adjusting, adjust the takeoff

on the scale (D) with the table adjustment

lever and re-tighten the locking handle (6).

With longer work pieces (longer than the

loading and unloading table), a dolly (special

accessory) or something similar has to be

used.

Thicknessing – machine set-up Fig. 9.0,

9.1, 9.2.

Changing from dressing to thicknessing

Unlock the jointer tables on both sides by

unclamping and removing both cam levers fig.

9 (9).

Push both tables up by the handles fig. 9 (12)

until the catch fig. 9.1 (E) clicks into place.

Rotate the ejection hood for shavings (8)

upwards until it clicks into place with the spring

U-bolt fig. 9.2 (F).

Extraction can then take place in conjunction

with an extraction unit.

Thicknessing – table adjustment fig. 10

The thicknessing table can be height-adjusted

with the handwheel (11) and it is secured

against displacement with the thicknessing

table clamp (10)

The integrated position display (G) shows the

aperture height.

One turn corresponds to 2 mm.

Always keep the thicknessing table as well as

the jointing tables free from resin.

Adjusting the scale during planing fig. 10

If there are irregularities, the scale (G) can

be adjusted. For this, loosen both mounting

screws, align the scale exactly and tighten

both screws again.

Automatic infeed in thicknessing operation

fig. 11

The automatic infeed is switched on and off

via the infeed locking lever (7).

Position top = on

Position bottom = stop

When the infeed is switched on, the wood

is automatically fed in and a precise and

consistent surface is the result.

During dressing, it is recommended to turn the

infeed off.

The infeed can also be turned off for safety

reasons.

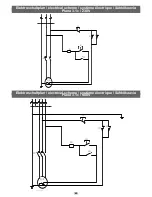

V-belt tension motor

Warning! Always disconnect the mains plug

during all re-tooling and adjusting work.

Tension the v-belt again after 3 hours of initial

operation. The belt tension also has to be

checked regularly after 40 operating hours

and, if needed, tensioned again.

Jointer work – cutterblock cover fig. 5

When dressing up to a 100 mm work piece

width, the cutterblock cover has to cover the

work piece and the cutterblock from the top. If

the work piece is wider than 100 mm, set the

guard rail of the cutterblock cover to the width

of the work piece. Make sure you put the flat

of the hand with all five digits together and

extended on the work piece.

1 Jointing fence

2 Cutterblock cover

Joining, fig. 6

For this procedure, use the jointing fence.

Place the cutterblock cover on the jointer table

and set the guard rail to the width of the work

piece.

Press the work piece against the planing

fence and guide it over the cutterblock with

both hands. As soon as the board reaches far

enough into the unloading table, put your left

hand on it and push it over the cutter without

stopping.

Jointer work – ejection of shavings fig. 8

During jointer work, the jointer table has to be

locked.

The extraction hose must be attached to the

extraction hood.

Extraction can then take place in conjunction

with an extraction unit (special accessory).

Diameter of the extraction port – 100 mm

Operating instructions

■

SET-UP AND ADJUSTMENT OF THE MACHINE

• Carry out work such as re-tooling, adjus-

ting, measuring and cleaning only when the

motor is switched off. Disconnect the mains

plug and wait for the rotating tools to stop

moving.

• All protective and safety equipment must be

re-attached immediately after completing

repairs and maintenance.

•

Replace faulty planing knives (flaws or

similar) straight away. See Replacement of

knives!

• Check the effectiveness of the return pre-

vention system before every process step.

The hook-tips must be sharp.

• All protective and safety notices must be

re-attached immediately after completing

repairs and maintenance.

■

THICKNESSING AND JOINTER WORK

• Maximum revolutions of the cutterblock

4000 1/min

• The cutterblock has been manufactured in

accordance with DIN EN 847-1.

• Start the process only when full revolutions

have been reached.

• Keep the operating area of the machine free

from shavings and wood debris.

• Use an extraction unit to extract shavings

and wood dust. The flow rate at the extrac

-

tion port must be 20 m/s.

• Work only with sharpened planing knives.

Blunt planing knives increase the risk of

recoil.

• Thickenessing: Feed with thicker work piece

end at the front, hollow side downward. Ma-

chine max. 2 work piece at one time, feed

on both outer sides.

• When working on longer work pieces

(longer than the loading table), use dollies

(special accessory).

• Dressing: When dressing up to a 100 mm

width work piece, the cutterblock cover has

to cover the work piece and the cutterblock

from the top. If the work piece is wider than

100 mm, set the guard rail of the cutterblock

cover to the width of the work piece. Make

sure you put the flat of the hand with all five

digits together and extended on the work

piece.

• Joining: The work piece is positioned

against the jointing fence. Set the guard rail

of the cutterblock cover to the width of the

work piece and place it on the table.

• Dressing and joining of small cross sections

(slats): During dressing, the work piece is

pushed forwards with hands sitting flat on

it, as is the case with work pieces up to a

width of 100 mm. During joining, the work

piece is pushed against the stop with both

hands, fists closed, and pushed forwards.

The guard is positioned at the fence and lies

on the work piece.

• Dressing and joining of short work pieces

(min. length 150mm): During dressing, the

work piece is pressed on the loading table

with a flat hand and pushed forwards with

the push block guided by the right hand. The

left hand glides over the guard. As soon as

the work piece lies on the unloading table,

the pressure from the left hand is changed

to the unloading table. During joining, the

work piece is pressed against the fence and

the table with the left hand, fist closed, and

GB

19

Summary of Contents for plana 3.1c

Page 4: ...1 1 3 4 2 6 5 12 10 8 9 13 7 11 4...

Page 5: ...2 2 5 3 3 1 A B C 3 4 5 2 1 6 2 1 7 5 6 D 8 D 5...

Page 6: ...9 9 1 9 2 10 11 12 12 1 13 12 9 E 8 7 K L M F G 10 11 D 6...

Page 23: ......

Page 25: ......