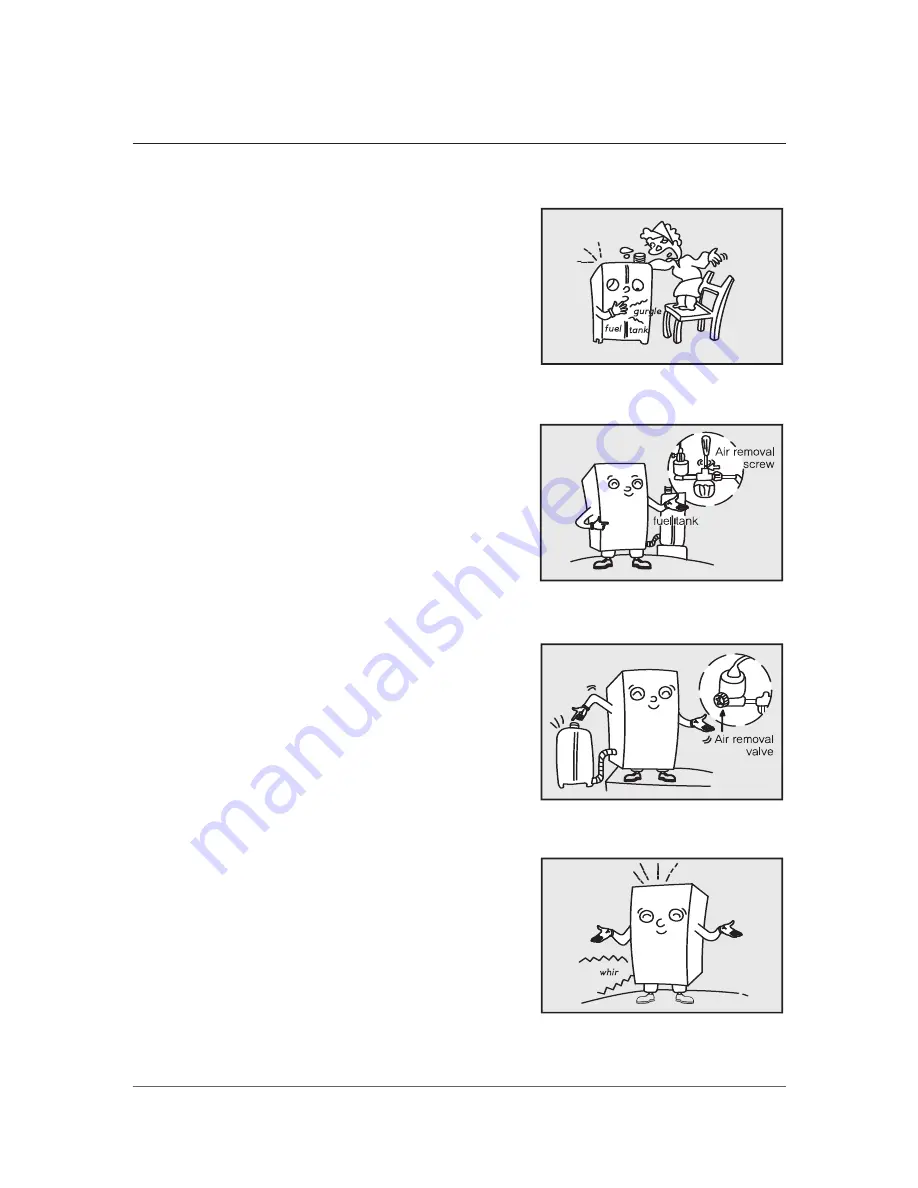

Avoid complete emptying of the oil tank.

This can lead to air being introduced to

the fuel system and may result in ignition failure.

the fuel supply line to vent. When oil starts to

In negative head oil supply applications the

fuel supply line must be purged using the

screw must be in the tightened position.

oil pump vent screw. For this the oil

fi

lter

Open the oil pump vent screw and switch

on the power to the boiler. After 6-7 seconds

the pump has purged the air and the

“CHECK” light will show on the control panel.

The boiler will stop.

Loosen the screw in the oil

fi

lter. This will allow

fl

ow re-tighten the screw (this is only possible

in positive head oil supply applications).

and that the low water level alarm is not activated.

of

fl

ammable materials.

Voit free boiler call(orange cable)

warning connecting power to the boiler

call will damage the control panel.

Ensure that there is su

ffi

cient water in the system

Take care when positioning the boiler.

Do not locate in the immediate vicinity

suitable measurement equipment to ensure

Con

fi

rm that the ignition and combustion of the

boiler are normal. Use the

fl

ue gas test port and

correct combustion is taking place. If the boiler is

power via the controller. Do not plug out the

boiler as this will de-activate the frost protection.

The domestic hot water supply is not

recommended for potable use.(Combi only)

not being used for extended periods turn o

ff

the

How to use

20

Purging the oil supply