14

SAS 1SF - Twin Screw Feeder Assy & Control - APRIL 2020

CLEANING METHOD

CLEANING OF THE SCREW FEEDER

With the machine turned off and disconnected from the power line, use a dry and clean

cloth to clean the exterior of the machine, if necessary soaked with a suitable non-toxic

and non-abrasive detergent.

Do not wash the machine with a high pressure water jet around the

electric motor.

For the body cleaning, once it has been disassembled, it is possible to use water

because no electric components exposed are present and the materials allow this

method.

The modular assembling of the machine permits an easy disassembling, easing the

cleaning and sanitizing procedures during a change of processed product.

Particularly, the motor group has no connection with the gears present on the screw

feeder body.

Disassemble the machine following the operations listed below:

1. Unwire the machine from the power line

2. Release the hopper from the screw feeder body loosening the nuts positioned

under the flange and rotating toward the outside the fixing hooks

3. Take the frontal of the screw feeder body off after loosening the locks (knobs or

nuts) using the suitable tools and, if they are present, loosening the grub screws

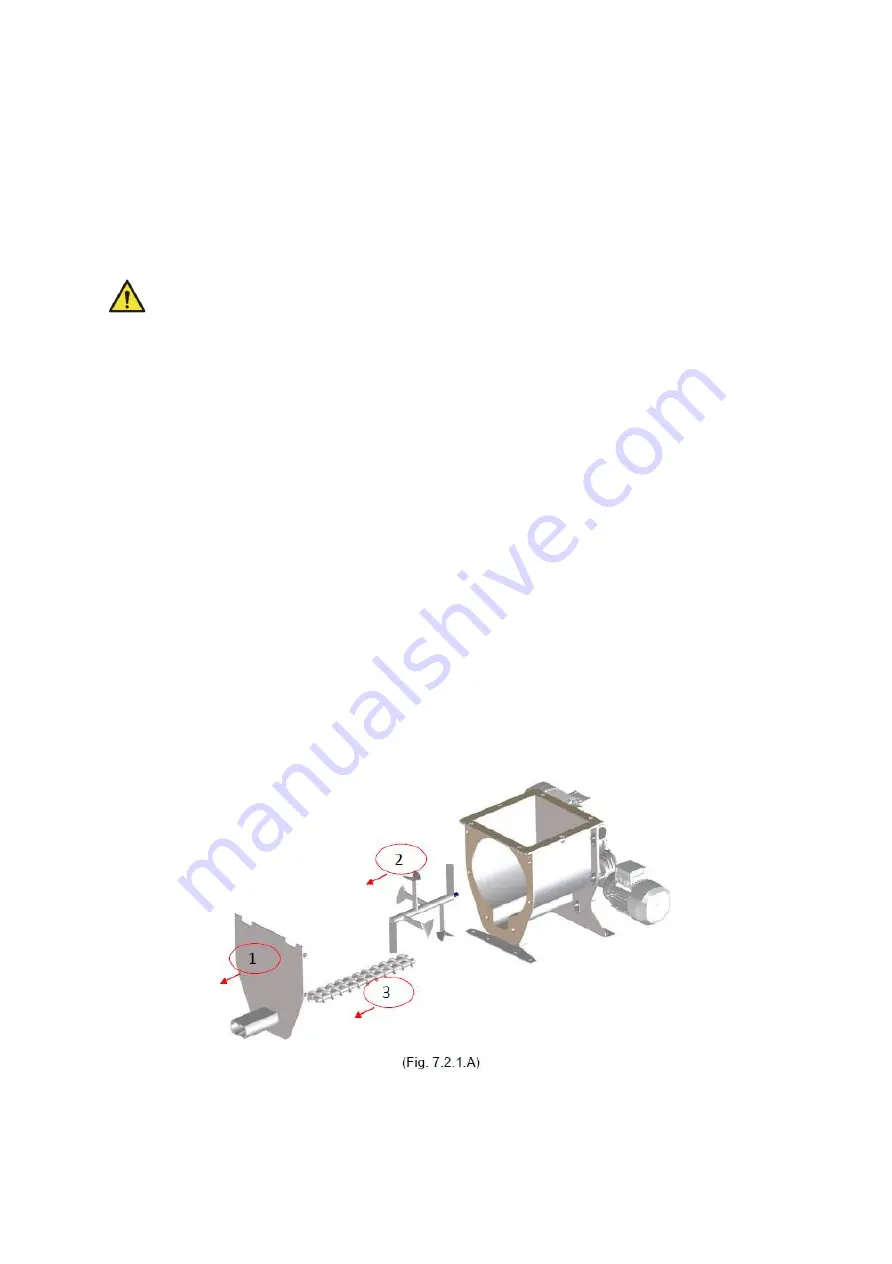

of the guide bearing present in the mixing paddle (Fig. 7.2.1.A).

4. Loosen the break-bridge agitating paddle always clockwise and take it off from

the screw feeder body (Fig. 7.2.1.A)

5. Loosen the endless screws always clockwise and take them off from the screw

feeder body (Fig. 7.2.1.A).