26

MECHANICAL ADJUSTMENTS

2-3:

2-2:

When the Tape Running Mechanism does not work well,

adjust the following items.

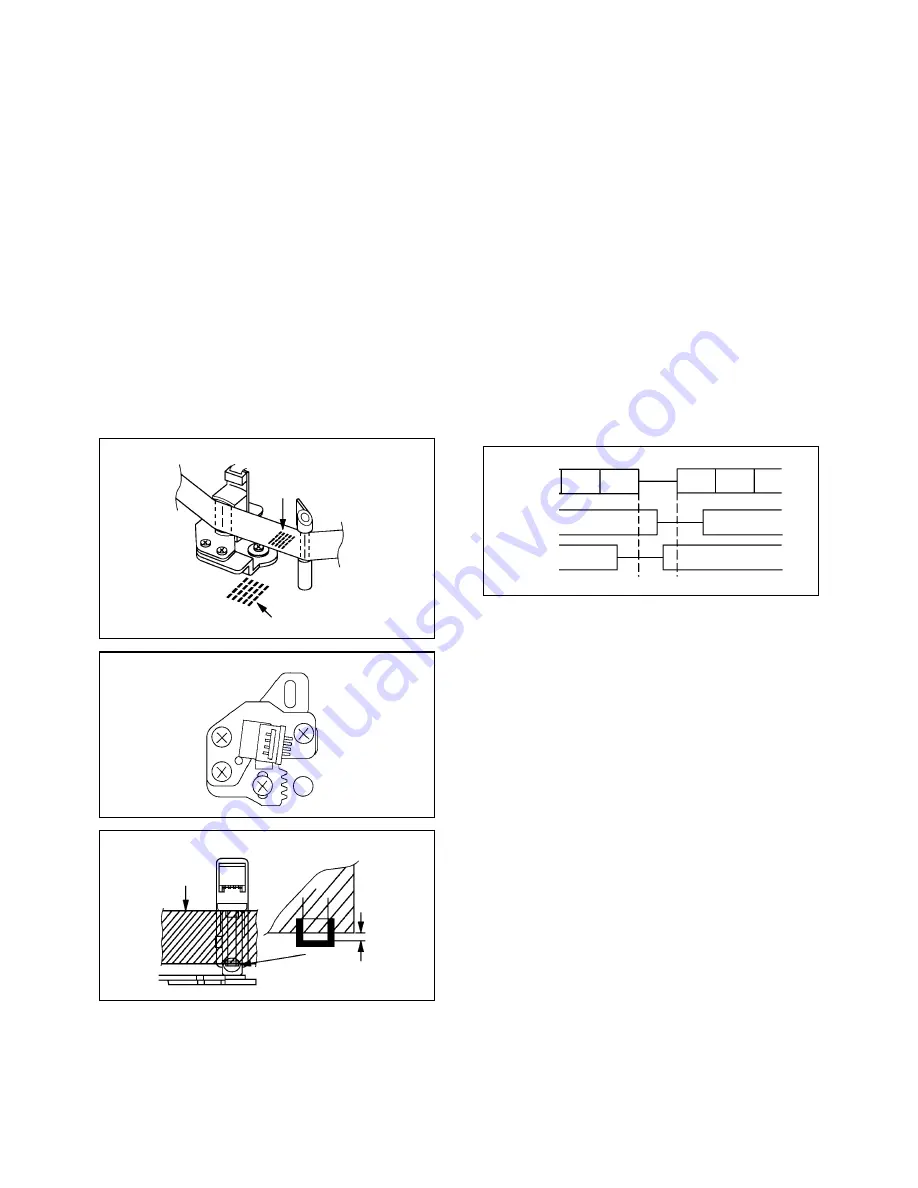

CONFIRMATION AND ADJUSTMENT OF AUDIO/

CONTROL HEAD

1.

2.

3.

4.

When the height is not correct, turn the screw

3

to

adjust the height. Then, adjust the 1~3 again.

Playback the VHS Alignment Tape (JG001C or JG001E).

(Refer to SERVICING FIXTURE AND TOOLS)

Confirm that the reflected picture of stamp mark is

appeared on the tape prior to P4 Post as shown in Fig. 2-

2-A.

a)

b)

Turn the screw

2

to set the audio level to maximum.

Confirm that the bottom of the Audio/ Control Head and

the bottom of the tape is shown in Fig. 2-2-C.

c)

When the reflected picture is distorted, turn the screw

1

clockwise until the distortion is disappeared.

When the reflected picture is not distorted, turn the

screw

1

counterclockwise until little distortion is

appeared, then adjust the a).

P4 Cap

Fig. 2-2-A

Audio/Control Head

1

3

2

Fig. 2-2-B

Audio/Control Head

Fig. 2-2-C

TAPE RUNNING ADJUSTMENT

(X VALUE ADJUSTMENT)

Confirm and adjust the height of the Reel Disk.

(Refer to item 1-1)

Confirm and adjust the position of the Tension Post.

(Refer to item 1-2)

Adjust the Guide Roller. (Refer to item 2-1)

Confirm and adjust the Audio/Control Head.

(Refer to item 2-2)

Connect CH-1 of the oscilloscope to TP4001, CH-2 to

TP4002 and CH-3 to HOT side of Audio Out Jack.

Playback the VHS Alignment Tape (JG001U or JG001V).

(Refer to SERVICING FIXTURE AND TOOLS)

Press and hold the Tracking-Auto button on the remote

control more than 2 seconds to set tracking to center.

Set the X Value adjustment driver (JG153) to the

4

of

Fig. 2-2-B. Adjust X value so that the envelope waveform

output becomes maximum. Check if the relation between

Audio and Envelope waveform becomes (1) or (2) of Fig.

2-3.

1.

2.

3.

4.

5.

6.

7.

8.

4

Audio/Control Head

Reflected picture of

Stamp Mark

Stamp Mark

Tape

0.25

±

0.05mm

Envelope

CH-3

Audio

(1)

(2)

Fig. 2-3

2-4: CONFIRM HI-FI AUDIO (Hi-Fi model only)

Connect CH-1 of the oscilloscope to TP4001 and CH-2 to

the Hi-Fi Audio Out Jack.

Playback the VHS Alignment Tape (JG001R). (Refer to

SERVICING FIXTURE AND TOOLS)

Press and hold the Tracking-Auto button on the remote

control more than 2 seconds to set tracking to center.

Press the Tracking Up button and count number of steps

which the audio output is changed from Hi-Fi (10KHz) to

MONO (6KHz).

Press and hold the Tracking-Auto button on the remote

control more than 2 seconds to set tracking to center.

Press the Tracking Down button and count number of

steps which the audio output is changed from Hi-Fi

(10KHz) to MONO (6KHz).

If the difference are more than 3 steps, set the X Value

adjustment driver (JG153) to

4

of Fig. 2-2-B. Change the

X Value and adjust it so that the value becomes within 2

steps.

1.

2.

3.

4.

5.

6.

7.