9. Final Driving Mechanism

9-2

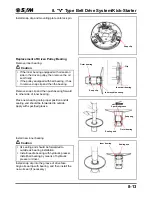

Maintenance Information

Limited usage of gear oil: gear oil #140

Recommended oil: Bramax serial oil.

Oil quantity: 110 c.c. (100 c.c. as replacement)

Torque Values:

Mission cover bolt

2.4~3.0kgf-m

Mission oil drain bolt

1.0~1.5kgf-m

Mission oil check bolt 1.0~1.5kgf-m

Troubleshooting

Trouble Diagnosis

Engine can be started but scooter cannot be moved

1. Damaged drive gear

2. Burnt out or seized drive gear

Noise

1. Seized, worn or damage gear

2. Worn or loose bearing

Gear oil leaks

1. Excessive gear oil.

2. Worn or damage oil seal

Summary of Contents for JET 4R

Page 1: ......

Page 38: ...3 Lubrication System 3 6 ...

Page 106: ...12 Brake System 12 2 Rear Drum Brake System 0 8 1 2kgf m 11 0 13 0kgf m 0 8 1 2kgf m ...

Page 118: ...12 Brake System 12 14 Notes ...

Page 134: ...14 Rear Wheel Rear Cushion 14 6 Note ...

Page 163: ......