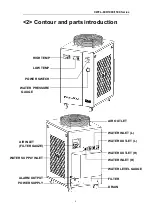

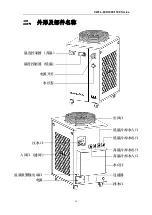

CWFL-800/1000/1500 Series

17

感谢您购买广州特域机电有限公司的产品,请在使用前仔细阅读使用安装

说明书,并妥善保管。

本使用安装说明书并非质量保证书,对印刷错误的更正

,

所述信息谬误的勘

误,以及产品的改进,均由广州特域机电有限公司随时做出解释,恕不预先通知,

修正内容将编入再版使用安装说明书中。

一、使用注意事项

1

、请确保电源插座接触良好并且地线可靠接地!

2

、请确保冷水机的工作电压稳定、正常!

由于制冷压缩机对电源电压比较敏感,我公司标准产品的正常工作电压为

210~240V(110V

机型为

100~120V)

。如果确实需要更宽的工作电压范围,

可以另行定制。

3

、电源频率不匹配会导致机器损坏!

请根据实际情况,使用

50Hz

或

60Hz

的机型。

4

、为保护循环水泵,严禁无水运行!

新机装箱前都排空了储水水箱,请确保水箱注水后再开机,否则水泵极易损

坏。当水箱水位在水位计绿色(

NORMAL

)范围以下时,冷却机制冷量会轻

微下降,请保证水箱水位在水位计的绿色(

NORMAL

)范围内。严禁使用循

环泵排水!

5

、请确保冷水机入风、出风通道顺畅!

冷水机上面的出风口距离障碍物要留有

50cm

以上的距离,侧面的入风口

离障碍物要求距离在

30cm

以上。

6

、入风口的滤网必须定期清洗!

必须定期拆洗防尘网

,

防尘网严重堵塞会引起冷水机故障。

7

、请注意冷凝水的影响!

当水温低于环境温度,并且环境湿度较大时,循环水管与被冷却器件表面会

产生冷凝水。当出现以上情况时,建议调高水温或对水管与被冷却器件进行保

温。

8

、本产品为工业设备,请勿让非专业人士操作。

Summary of Contents for CWFL-800

Page 1: ...CWFL 800 1000 1500 DUAL TEMPERATURE INDUSTRIAL CHILLER USER MANUAL...

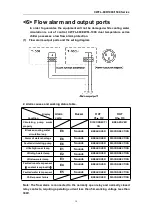

Page 15: ...CWFL 800 1000 1500 Series 15 CWFL 800 1000 1500...

Page 16: ...CWFL 800 1000 1500 Series 16 17 18 19 20 23 24 25 28...

Page 18: ...CWFL 800 1000 1500 Series 18...

Page 19: ...CWFL 800 1000 1500 Series 19 1 2 3 4 1 2 3 4 5 6 CWFL 800 1000 1500 20...