Disassembly and Reassembly

Samsung Electronics

1-15

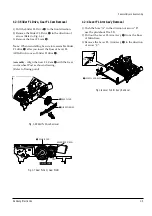

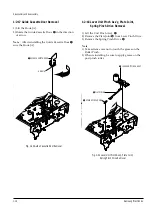

1-2-23 Plate Ground Deck, Cylinder Ass’y Removal

1) Remove the 3 Screws

Œ

.

2) Lift the Plate Ground Deck

´

.

3) Lift the Cylinder Ass’y

ˇ

.

Assembly

:

1) Match the 3 holes in the bottom of Cylinder ass'y

ˇ

to the 3 holes of Main Base as attending not to

drop or knock the Cylinder ass'y

ˇ

.

2) Tighten the 1 Screw

Œ

.

3) Match the Plate Ground Deck

´

to the Hole of

Base Main.

4) Tighten the other 2 Screws

Œ

.

Note

:

1) Take care not to touch the Cylinder Ass'y

ˇ

and

the tape guide post at reinstalling.

2) When reinstalling, Don't push down too much on

Screw Driver.

Œ

3 SCREWS

´

PLATE GROUND DECK

ˇ

CYLINDER ASS'Y

Fig. 1-29 Plate Ground Deck, Cylinder Ass’y Removal

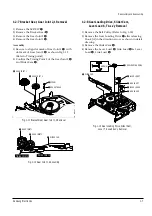

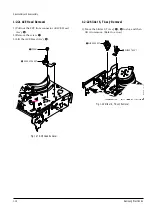

1-2-24 Belt Pulley Removal

1) Remove the Belt Pulley

Œ

.

Note

: Take extreme care not to get grease on Belt

Pulley

Œ

at assembling or reassembling.

Œ

BELT PULLEY

Fig. 1-30 Belt Pulley Removal

1-2-25 Level Head Cleaner Ass’y Removal

(Optional)

1) Release the Hook

Œ

.

2) Lift the Lever Head Cleaner Ass’y

´

.

Œ

HOOK

´

LEVER HEAD CLEANER ASS'Y

SLEEVE-HEAD CLEANER

Fig. 1-31 Level Head Cleaner Ass’y Removal

Summary of Contents for VR5140C

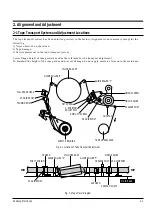

Page 10: ...2 6 Alignment and Adjustment Samsung Electronics MEMO ...

Page 18: ...Exploded View and Parts List 3 8 Samsung Electronics MEMO ...

Page 28: ...4 10 Samsung Electronics Electrical Parts List MEMO ...

Page 32: ...Schematic Diagrams 5 4 Samsung Electronics 5 2 Logic Ø ˆ Œ ˇ ...

Page 34: ...Schematic Diagrams 5 6 Samsung Electronics 5 3 Audio Video ˇ ˆ Ø Œ ...

Page 36: ...Schematic Diagrams 5 8 Samsung Electronics 5 4 Hi Fi Option Œ ˇ ...

Page 40: ...Schematic Diagrams 5 12 Samsung Electronics 5 7 Display LED Lamp VR8140C 5140C ...

Page 59: ...1 18 Samsung Electronics Disassembly and Reassembly MEMO ...